Study and fabrication of cold plasma treatment for mushrooms spawn

Norhayati Ahmad, Linda Agun, Fakhrur Razi Mohamad Malek, Norizah Redzuan and Raja Kamarulzaman Raja Ibrahim

Faculty of Engineering University Teknology Malaysia, Malaysia

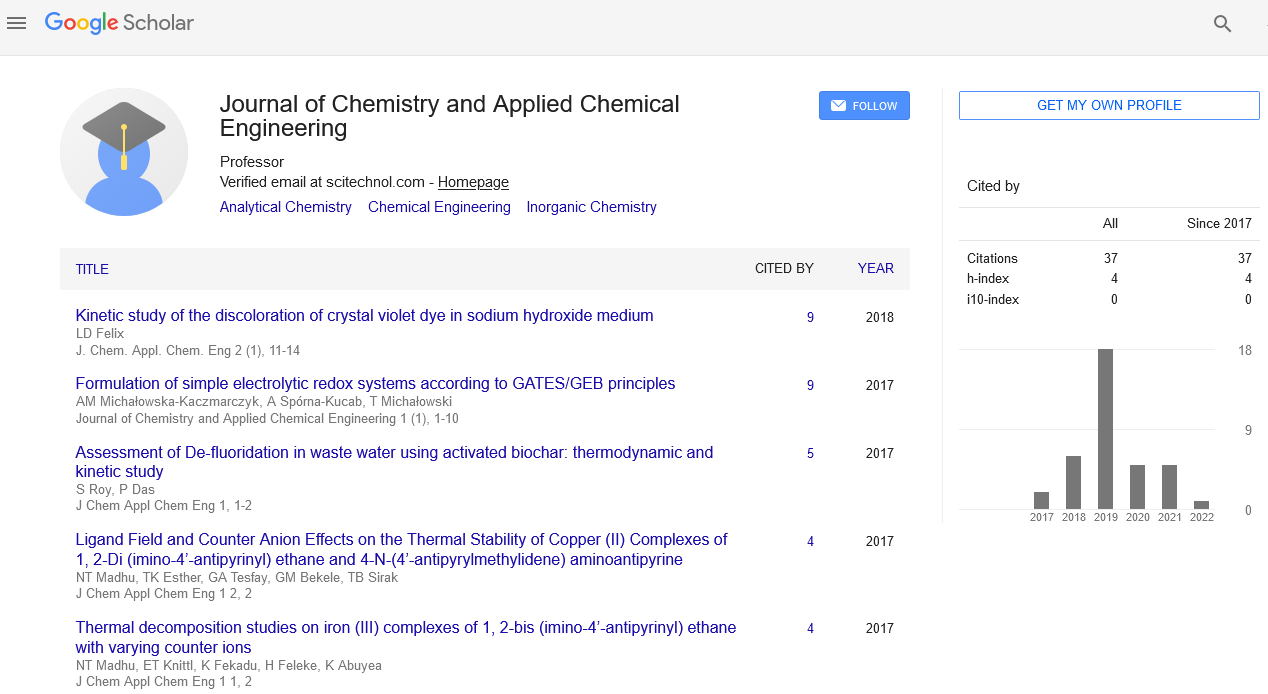

: J Chem Appl Chem Eng

Abstract

Cold plasma (CP) technology has found favor in the agricultural industry for changing seed coat structures, increasing the permeability of seed coats and stimulating seed. However, there are still leaking study of mushroom spawns application. The Pleurotus ostreatus (oyster mushrooms) spices spikes in global demand, encouraging Malaysia to take advantage of the lucrative trade. Therefore, the objectives of this study are to evaluate the mushroom spawn’s wettability for mushrooms germination rate by using CP technology. By using a novel CP pen as shown in Figure, the mushroom spawn will treated by using discharge air. The air generates in a petri dish with a flow rate of 5 L/ min by considering three different time exposures (0, 15 and 30 seconds) with 8 kV of supply voltage. Stainless steel rod is a material for electrode pen discharge. The SEM and contact angle analysis were conducting to study the changes in the surface morphology of the plasma treated spawns. The results show an increment of treatment time, increase the mushroom spawn pores and wettability. This creates surface more hydrophilic thus spawn absorbs more water and shorten the germination rate. Based on the results, it can conclude that the CP application can significantly change the spawn wettability and textural.

Biography

Norhayati Ahmad is the faculty of School of Mechanical Engineering, & Engineering Universiti Teknologi Malaysia,81310 Johor Bahru, Johor, Malaysia, Faculty of Science, Universiti Teknologi Malaysia, 81310 Johor Bahru, Johor, Malaysia

E-mail: nhayati@fkm.utm.my

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi