Effect of particles size on sintering quality and mechanical properties of the peanut husk powder / pes composites produced via selective laser sintering

Aboubaker Idriss Bolad Idriss

Northeast Forestry UniversityCollege of Mechanical and Electrical Engineering, China

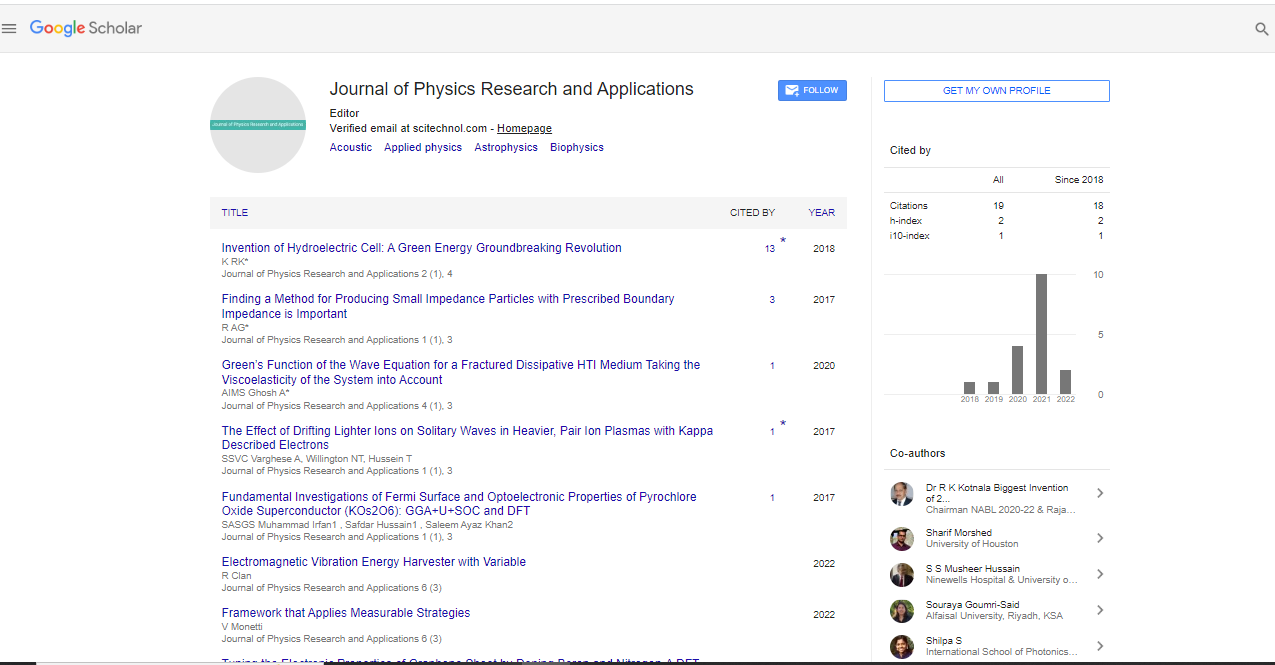

: J Phys Res Appl

Abstract

In order to improve the mechanical strength of wood-plastic SLS parts, reduce the pollution associated with agricultural waste, and increase the availability materials use in laser sintering technology, while simultaneously valorizing agricultural waste. Herein, a new composite of peanut husk powder (PHP)/polyether sulfone (PES) (PHPC) was developed for SLS additive manufacturing that is low cost, friendly, and sustainable materials. Initially, the glass transition temperatures (Tg) and thermal decomposition of PHP and PES powders were determined to avoid the produced PHPC parts from deformation and warping during SLS, while estimate the preheating temperature of PHPC composite. The formability of PHPC specimens with various PHP particle size was firstly tested via single-layer sintering to ensure that can be used in SLS. Moreover, PHP and PES powders particle distribution, microstructure of PHPC specimens, and the PHPC SLS parts (both before and after breakage in mechanical tests and waxing processing), respectively were inspected using scanning electron microscopy (SEM). The density, mechanical strengths, residual ash content, dimensional precision, and surface roughness of the various PHPC SLS parts were measured and analyses. Through the tests results, the relationship between various PHP particles sizes and mechanical properties of the PHPC SLS parts were determined. According to the combined results demonstrated that, a particle size of PHP = (<0.125 mm) resulted in the highest mechanical properties, when comparing with other PHP particle size and pure PES. Thus, the measured bending strength, tensile, impact strength, residual ash content, and density for produced PHPC were 14.1 MPa, 6.076 MPa, 2.12 kJ/cm2, 1.2 %, and 1.1825 g/cm3, respectively. To further improve the surface roughness and mechanical strength of these parts, the post-processing treatment was utilized.

Biography

Aboubakar Idriss Bolad Idriss is a PhD student in Northeast Forestry University, College of Mechanical and Electrical Engineering, Harbin 150040 China. He obtained his Master degree in the Mechanical egineering (Production department) from the Sudan University of science and technology. He is qualified Mechanical Engineer with a proven track record within the Mechanical egineering and industrial technologies. He has been graduated from University of Nyala, Sudan, BSc in Mechanical Engineering. His previous experience involved being a member of both Faculty board and department of mechanical egineering. Besides that he is a member on the Research Council of the Faculty of Engineering Science team and lecturer at the University of Nyala- Sudan. He has published over 7 Science Citation Index Expanded (SCI) papers in peer-reviewed journals during his PhD study.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi