Review Article, J Nucl Ene Sci Power Generat Technol Vol: 11 Issue: 6

Review of the Thermal Comfort and Energy Conservation Performance of Phase Change Materials (PCMs) In the Building Envelope

Fitsum Andualem* and Pranil Sawalakhe V

Department of Mechanical Engineering, Jain University, Bangalore, India

*Corresponding Author:Fitsum Andualem, Department of Mechanical Engineering, Jain University, Bangalore, India;E-mail: prasannamishra234@gmail.com

Received date: 09 February, 2022, Manuscript No. JNPGT-21-46976;

Editor assigned date:11 February, 2022, PreQC No. JNPGT-21-46976 (PQ);

Reviewed date: 25 February, 2022, QC No. JNPGT-21-46976;

Revised date: 13 April 2022, Manuscript No. JNPGT-21-46976 (R);

Published date: 02 May 2022, DOI: 10.4172/2325-9809.1000283

Citation: Fitsum A, Pranil SV (2022) Review of the Thermal Comfort and Energy Conservation Performance of Phase Change Materials (PCMs) In the Building Envelope J Nucl Ene Sci Power Generat Technol 11:6.

Abstract

Throughout entire world, the electricity used to create energy demand and boost thermal comfort has risen significantly; policymakers and stakeholders are reinforcing policies to reduce building energy usage. The energy consumption is usually decreases by means of the Phase Change Material (PCM) inside the construction. It is very much important that PCM be used like Thermal Energy Storage (TES) because its increase in power density and low level temperature transition range. Various PCM materials, their temperature phase shift and PCM incorporation methods within residential buildings envelope will be elaborated in this paper. This PCM integrated gypsum board is highly acceptable in construction industry for the future due to its availability and high demand. Finally, all researchers agree that PCMs are a promising material in the construction industry for energy conservation and thermal fluctuation control, but there is a gap in the cost viability assessment and dependence on weather conditions of the area, which can further be studied in near future.

Keywords: Building envelope; Energy conservation; Phase change material; Temperature; Thermal comfort

Introduction

Energy demand is growing for the world as a whole. It creates a scarcity of energy consumed in buildings. The substitution of energy supply sources from traditional to renewable or self-feeding sources is a result of this. The construction industry now absorbs substantial quantity of energy generated worldwide mainly meant for heating, ventilation and air conditioning system every day. So policymakers and the government should concentrate deeply on implementing policies in this field. Heat Storage Technology (HST) is one of the most used methods for energy management in addition to thermal relief. Due to this Phase Change Materials (PCM) are used to store latent heat throughout the daytime while all through the night time it release the warehoused heat by phase changes. In this case, we only address the phase shift from liquid to solid or vice-versa of said material i.e. PCM. Furthermore, they are promising materials for energy conservation and thermal comfort via this phenomenon. Thermal energy does have a higher power capture or storage potential over sensible temperature, allowing these to conserve more power along with heat energy within constructions [1,2].

Using PCMs in the building envelope has the following advantages. It can increase the building envelope's heat power, control indoor temperature fluctuations and enhance thermal comfort. In contrast, at the time the PCMs are coupled with the air conditioning system, by shifting the pick load demand of electricity, it reduces the electrical power used by Heating, Ventilation, and Air Conditioning (HVAC) systems because these materials are becoming increasingly desirable in the construction industry [3].

In the resource-saving construction domain the usage of the PCM envelope and study on enhancing the interior thermal conditions has become increasingly common [4]. This review paper focuses primarily on research papers that have been carried out to assess the efficiency of resource savings and thermal satisfaction PCM. This paper also included the techniques and the methods used for the implementation of PCMs in the building [5-7].

Literature Review

Phase change material’s for buildingsHeat can always be kept either in form known as Latent Heat Storage (LHS) or in its other form known as Sensible Heat Storage (SHS). Due to its high conversion efficiency and low heat fluctuation, LHS materials utilized to store a heat directly from solar radiation or ambient temperature and release it when required. Material classification and comparison of PCMs are discussed in Table 1 and will allow the selection of PCM material that matches our building envelope [8-10].

ClassificationPCMs are divided into three varieties depending upon their status of phase transformation or shift from one stage to other [11]:

- Solid-solid (S2S)

- Solid-liquid (S2L)

- Liquid-gas (L2G)

For one of the storage i.e. thermal energy storage, the very well suited type among the above three are S2L PCMs like organic (Paraffin or Non-Paraffin based), inorganic (Salt Hydrate or Metallic) and Eutectics PCMs as depicted below in Figure 1. A summary of the many types of PCMs is provided in Table 1 and Figure 1. [12].

| Type | Merit | Demerits |

|---|---|---|

| Organic PCMs | Incredibly wide temperature range. | Less thermal conductivity (around 0.2 W/m K). |

| Good heat of fusion. | Large volume change. | |

| No existence of super cooling. | Fire resistance. | |

| Chemically stable | ||

| Compatibility is good. | ||

| Inorganic PCMs | Fusion heat is incredibly strong. | Super cooling problem. |

| High thermal conductivity. | Attack by corrosion. | |

| Less change in volume. | ||

| Low cost. | ||

| Eutectics | Applicable melting temperature. | Shortage of currently avaiable Thermo-Physical Test data. |

| Good therma lstorage density. |

Table 1: Illustrates the contrast of the various forms of Phase Change Material (PCM)[4]. The merits and demerits of different types of PCM are also discussed here in this table.

| PCMs | Heat of fusion (kJ/Kg) | Melting temperature (°C) | Specific heat (kJ/kg K) | Thermal conductivity (W/m k) | Type |

|---|---|---|---|---|---|

| Bustyl stearate | 140 | 19 | - | - | Organic |

| 1-Dodecanol | 200 | 26 | - | - | Organic |

| 1-Octadecane | 200 | 28 | - | - | Organic |

| Paraffin C16-C18 | 152 | 20-22 | - | - | Organic |

| Paraffin C13-C24 | 189 | 22-24 | 2.1 | 0.21 | Organic |

| Paraffin C18 | 244 | 28 | 2.16 | 0.15 | Organic |

| Vinyl Stearate | 122 | 27-29 | - | - | Organic |

| Dimethyl sabacate | 120-135 | 21 | - | - | Organic |

| Polyglycol E600 | 127.2 | 22 | - | 0.1897 (1) | Organic |

| 45/55 capric+lauric acid | 143 | 21 | - | - | Organic |

| Propy1 Palmitate | 186 | 19 | - | - | Organic |

| Octadecy1 3-mencaptopr opylate organic | 143 | 21 | - | - | Organic |

| KF.4H20 | 231 | 18.5 | 1.84 (s) 2.39 (1) |

KF.4H2O | Hydrate salts |

| Mn (N03).6H2O | 125.9 | 25.8 | - | - | Hydrate salts |

| Cacl2.6H2O | 171 | 29.7 | 1.45 (s) | - | Hydrate salts |

Table 2: Illustrates the physical characteristic possessions of organic and hydrated salt PCM

Classification of literature review based on objective, methods and phase change materials temperature rangeThe classification is based on the purpose, temperature of the phase shift, the techniques and software used by the author and the parameters used to evaluate the simulation work. Table 3 shows different researchers and practitioners and their publications on PCM performance analysis in building envelope and thermal storage system [13].

| S.no | Author | Publication Year and Page No. | Obhective | Phase change Temperture | Method and Tools | PCM material selected and parameter | Future Scope Study |

|---|---|---|---|---|---|---|---|

| 1 | D. Zhou, C.Y. Zhao, Y.Tian | Review 92 (2012) 593-605 Applied energy. | Previous work on Latent thermal energy storage is summarize. | Thermal comfort temperture is 18°C and 30°C. | Different methods | One of the most significant parameters to remember when estimating a building's thermal effciency is the time lag decrement factor. | - |

| 2 | Barilelo Nghana, Fitsum Tariku. | Building and environment 2016 | Numerical and experimental validation is used to explore the ability of phase change materials. | 23°C | Energy Plus software, numerical and experimental studies. | Bio PCM is selected over paraffin based PCM. | |

| 3 | Naser P. Sharifi | Energy building 10-12-2016 | Evaluation of the effectiveness of PCM in gypsum bard by using impregnation to boost building thermal efficiency. | - | COMSOL Myltiphysics software. | - | Durability and fire rating of PCM, will be future study. |

| 4 | Yunhua Zhu | Analysis on the of phase change wall by the application of thermal isolation. | - | ANSYS finite emement analysis software is used for numerical simulation | Paraffin phase-change materials, for concrete, its heat conductivity coefficent is λ=1.74 (W/m2.K), | - | |

| 5 | Daniel M. madyira | Procidia manufacturi ng 7 (2016) 420-426 | Assessment on the performance of PCM rig. | 22-26 °C | Experimental method using test rig. An orgnaic PCM encapsulate aluminimum plate was used. | Paraffin based PCM Rubitherm RT25HC. | |

| 6 | Xiaoqin sun | Energy conversion and Manageme nt 120 (2016) 100-108 | Evaluate and present the heat trasfer theory of PCM board in the building envelope. | - | Methods used are energy and mass efficency (EME). | Evaluating parameters used in the building envelope are melting temperature, board thickness and PCMs's heat transder coefficient. | - |

| 7 | K.S. Reddy Vijay Mudgal and Tapas K. Mallick | 09-Sep-17 | Thermal performace of roof integrated with PCM is Investigated | - | FLUENT Inc and ANSYS Fluent are used for modeling and analusis. The thermo-physicla properties are calculated using the porosity technique. | The parameters used in this study were thickness, phase transition temperature, heat of fusion, and PCM layer. | |

| 8 | Amine Laaouat Ni | Energy procedia 139 (2017) 744-749 | To test the coupling on concrete blocks in order to improve the building thermal inertia. | 28°C | COMSOL Multi physics. Tubes are mounted (open. Closed and ventilated) and experimental devices are designed to compare the thermal response. | Paraffin and styrene-type polymer. | - |

| 9 | Dong Li, Yangyang Wn, Changyu luiGuoju n Zhang, Muslum Arici | Energy conversion and Management 172 (2018) 119-128 | To show the effect of NANO pariticle fraction and diameter on the temperture difference between the glass. | - | One of the effective methods to boost thermal efficiency is to add nano particles into the phase change material (PCM). | paraffin wax. | - |

| 10 | Song mengjie, Nuy Fuxin, Mao Nung, Hu Yanxin Deng Shiminge. | Energy and Building 158 (2018) 776-793 | Examine building envelope optimization techniques with wall, Roof, and Floor integration bounded phases change material. | - | A collection of devices for air conditioning, heating and ventilation combined with thermal energy storage. | Paraffin and binary organic acids. | |

| 11 | Y.B Tao, Ya-ling He | Renewable and Sustainable energy reviews 93 (2018) 245-259 | Design the performance improvement method for the latent heat storage system. | - | Nano Composite PCM, Finned tube, Porous Composite PCM, Cascading, Encapsulated PCM, PCM to enhance thermal efficiency in the LHS system are methods performed in this paper. | - | Develop highly effective methods of encapsulation for PCMs at high temperature. |

| 12 | H Hamdani | 2018 IOP Conf Ser.: Mater Sci Eng 434 012186 | On the walls of banda Aceh City, Indonesia, numerical analysis of building thermal properties is addressed. | 20-24°C, 24-28°C | Energy Plus software is selected. The macro-encapsulation process uses epoxy as a coating medium and graphite poweder is used to incerease thermal conductivity. | Beeswax and paraffin. | - |

| 13 | Beom Yeol Yun, Sungwoong Yang, Hyun Mi Cho, Seong Jin Chang, Sumin Kim | Environmental research 173 (2019) 480-488 | Heating techniques suitable for use in wooden buikdings are being investigated. | 28°C to 35°C | Macro-Packed PCM (MPPCM), as Shape stabilization is applied | PCMs based on paraffin are used, such as n-octadecane, n-eicosane, n-docosane and n-eicosane. | - |

Table 3: Illustrates the classification of literature based on objective, methods and phase change temperature range.

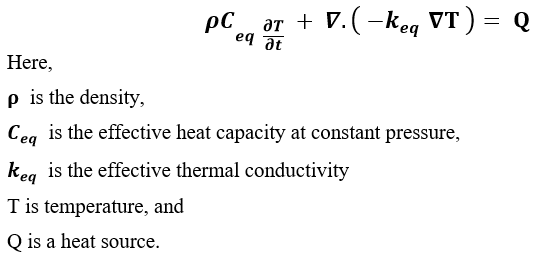

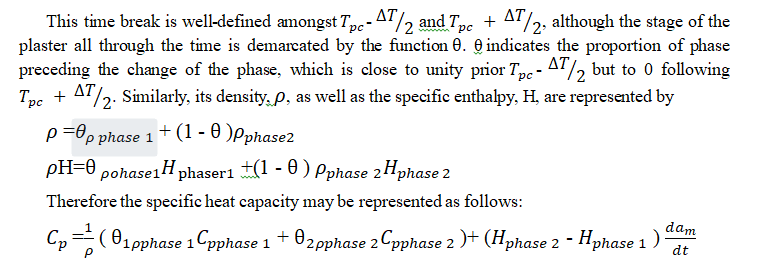

Numerical modelling formulasDuring the phase shift from solid to liquid, volume of the PCMs is changed, leading to a volumetric contraction. Every alteration inside the original system is represented using the solid PCM coordinates, whenever the solid PCM covers whole region. Considering there is no interaction within the liquid state, the conductivity formula using solid PCM parameters may be applied [14].

Whenever such PCM-enhanced plaster achieves its phase transition heat, it is anticipated that perhaps the phase shift take places across the time period [15].

Discussion

Study determines performance of phase transformation changes PCM within construction envelope depend on temperature of that area, PCM selected and incorporation method used. Researchers apply various methods and techniques used to analyse and simulate thermal physical properties of PCMs and also do experimental work to validate simulation work. The PCM materials are integrated in the heat and ventilation system or directly used for passive heating and cooling system with walls, ceilings, roof and floors. The materials for phase change will store a latent heat in a warm period of time and release it in a cold period. By encapsulation or by impregnation process, PCM may be used with gypsum board, mortar, bricks and blocks. The heat capacity and phase change temperature are the main parameters for selection of PCM material for specific building envelope. Finally findings show that by controlling pick electric demand and enhancing energy comfort, PCMs are promising stuff.

Experimentation and simulation are used to carry out the PCM modelling task. Due to the use of data and the precise temperature availability, experimental techniques are more accurate than simulation methods. The simulation programme, on the other hand, is simple to use and advanced. Building envelope having PCM within, has an advantage that reducing temperature fluctuations and picking demand periods by delaying temperature and heat transfer. In areas with high temperature variation and in extremely cold weather conditions, phase change materials are limited. Finally, phase change materials show that the world is transitioning from a traditional energy conservation strategy to a new mechanism. This has the potential to significantly reduce future energy usage in building sectors that utilize air conditioners [16].

Conclusion

This review paper covers the classification of PCMs, thermo-physical characteristics and extensive literature review on methods and instruments for improving efficiency. In walls, ceilings and floors, PCMs have been used to store latent heat, showing a substantial effect on minimizing temperature variations in building. We may enhance thermal efficiency in the latent Heat Storage System (LHS) system using encapsulated PCM, finned tube, Porous composite PCM, cascading PCM, Nano composite PCM techniques. This PCM integrated gypsum board is highly acceptable in construction industry for the future due to its availability and high demand. All the researchers agree that PCMs are effective innovations to support the energy efficacy besides thermal comfort of the envelope. The effectiveness of the reliance on PCM in weather conditions and the assessment of cost viability require additional effort in the research world, hopefully could be conducted in the near future.

References

- Sun X, Zhang Q, Medina MA, Lee KO, Liao S, et al. (2016) Parameter design for a phase change material board installed on the inner surface of building exterior envelopes for cooling in China. Energy Convers Manag 120: 100-108.

- Kylili A, Fokaides PA. (2016) Life Cycle Assessment (LCA) of Phase Change Materials (PCMs) for building applications: A review. J Build Eng 120: 100-108.

- Cai R, Sun Z, Yu H, Meng E, Wang J, et al, (2021) Review on optimization of phase change parameters in phase change material building envelopes. J Build Eng 35: 101979.

- Zhou D, Zhao CY (2010) Experimental investigations on heat transfer in phase change materials (PCMs) embedded in porous materials. Appl Therm Eng 31: 970-977.

- Tao YB, He YL (2018) A review of phase change material and performance enhancement method for latent heat storage system. Renew Sustain Energy Rev 93: 245-259.

- Nghana B, Tariku F (2016) Phase change material’s (PCM) impacts on the energy performance and thermal comfort of buildings in a mild climate. Build Environ 99: 221-238.

- Madyira DM (2017) Experimental Study of the Performance of Phase Change Material Air Cooling Rig. Procedia Manuf 7: 420-426.

- Reddy K, Mudgal V, Mallick T (2017) Thermal Performance Analysis of Multi-Phase Change Material Layer-Integrated Building Roofs for Energy Efficiency in Built-Environment. Energies 10: 1367

- Yun BY, Yang S, Cho HM, Chang SJ, Kim S, et al. (2019) Design and analysis of phase change material based floor heating system for thermal energy storage. Environ Res 173: 480-488.

[Crossref] [Google Scholar][Pubmed]

- Ali HM (2019) Applications of combined/hybrid use of heat pipe and phase change materials in energy storage and cooling systems: A recent review. J Energy Storage 26: 100986.

- Laaouatni A, Martaj N, Bennacer R, El Omari M, El Ganaoui M. (2017) Phase change materials for improving the building thermal inertia. Energy Procedia 139: 744-749.

- Hamdani H, Rizal S, Riza M (2018) Numerical simulation analysis on the thermal performance of a building walls incorporating Phase Change Material (PCM) for thermal management. IOP Conf Ser Mater Sci Eng. 434: 012186

- Kylili A, Fokaides PA. (2017) Numerical simulation of phase change materials for building applications: a review. Adv Build Energy Res 11: 1-25.

- Sharifi NP, Shaikh AAN, Sakulich AR (2017) Application of phase change materials in gypsum boards to meet building energy conservation goals. Energy Build 138: 455-467

- Song M, Niu F, Mao N, Hu Y, Deng S, et al. (2018) Review on building energy performance improvement using phase change materials. Energy Build 158: 776-793.

- Zhu N, Li S, Hu P, Lei F, Deng R (2019) Numerical investigations on performance of phase change material Trombe wall in building. Energy 187: 116057.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi