Review Article, J Nucl Ene Sci Power Generat Technol Vol: 14 Issue: 1

Review of External Preheating Techniques for Power Battery in Electric Vehicles at Low Temperatures

Zibo Ye1, Xingfeng Fu2*, Kai Wen3,4, Feng Pei4, and Hai Jiang3

1School of Automobile and Transportation Engineering, Guangdong Polytechnic Normal University, Guangzhou, China

2School of Civil Engineering and Transportation, South China University of Technology, Guangzhou, China

3Department of Physics, Tsinghua University, Beijing, China

4Department of Electronics Engineering, Peking University, Beijing, China

*Corresponding Author: Xingfeng Fu,

School of Civil Engineering and

Transportation, South China University of Technology, Guangzhou, China

E-mail: fxf1000@163.com

Received date: 11 May, 2024, Manuscript No. JNPGT-24-134706;

Editor assigned date: 13 May, 2024, PreQC No. JNPGT-24-134706 (PQ);

Reviewed date: 27 May, 2024, QC No. JNPGT-24-134706;

Revised date: 03 June, 2024, Manuscript No. JNPGT-24-134706 (R);

Published date: 10 June, 2024, DOI: 10.4172/2325-9809.1000393.

Citation: Ye Z, Fu X, Wen K, Pei F, Jiang H (2024) Review of External Preheating Techniques for Power Battery in Electric Vehicles at Low Temperatures. J Nucl Ene Sci Power Generat Technol 13:3.

Abstract

Electric drive vehicles offer a hopeful solution for significant decreases in greenhouse gas emissions and reliance on fossil fuels. Exploring efficient battery preheating techniques is essential due to the fact that harshly cold climates substantially decrease the discharge efficiency of electric vehicles, frequently necessitating lengthy warming periods for the battery upon startup. To this end, this paper reviews currently popular preheating strategies used in passenger electric vehicles. Initially, the postmortem analysis of the cycled anodes charged at low temperatures is reviewed briefly. Following this, detailed descriptions of different external preheating system designs for battery warm-up are presented. Furthermore, the improved charging strategies with the preheating devices such as traditional PTC water heaters and HVCH are elucidated. In addition, the use of electro thermal element preheating in early EVs and prototype vehicles for experimental research is discussed.

Keywords: External preheating technique; Current fluctuation;

Water heater; High-voltage coolant heater

Introduction

As the global Electric Vehicle (EV) market has flourished in recent years, the demand for advancements in battery technology and charging infrastructure will also increase. However, due to the reduced Li+ diffusivity in the electrolyte and increased charge transfer resistance, the deteriorated electrochemical performance of batteries hinders their application in EVs at low temperatures, especially in cold or high-latitude areas. By conducting specific heat capacity tests on the aged batteries after cycling tests at 0℃, it was observed that the heat generation of the cell increases rapidly when the State of Health (SOH) falls below 80% [1]. The subsequent thermal runaway experiments also discovered that the onset temperature of exothermic reactions and the thermal stability of Lithium-Ion Battery (LIB) decrease with more severe aging. Numerical simulation of a thermal runaway model for low-temperature cycling LIBs, which was constructed by coupling the decomposition chemical reaction model taking the aging effect into account with a thermal model, demonstrated that the cathode-electrolyte reaction was the largest heat source, and the second heat source was the anode-electrolyte reaction [2]. Fu et al., disassembled a power battery that had been in service for a long-term charging and discharging process at low temperatures [3]. When compared to the pristine anode, a significant color change from black to golden-yellow is observed in the charged state, indicating the pronounced formation of LiC6 on the surface of the battery’s anode electrode [4,5]. More severe irreversibility and a higher proportion of dead metallic lithium were detected in the postmortem morphology. The numerous small, flaky, and silvery lithium precipitates on the anode electrode suggest over-lithiation and a significant reduction in battery capacity. The formation of lithium precipitation should be avoided during the low-temperature charging process of the power battery. S. Barcellona designed a hybrid energy storage system that combines LIBs with a directly parallelized small super capacitor [6]. Tests in low-temperature conditions have demonstrated the effectiveness of the hybrid system, which can start the EV without the need to wait for the pre-heating. But the battery capacity of 10 Ah studied in the tests is significantly lower than the capacity typically used in electric vehicles. From initial temperatures of -20℃ and -30℃, there is an 11.3% and 31.4% improvement in discharge energy, respectively, when heating up to its optimum temperature compared to no pre-heating. Fly et al., concluded that a battery pre-heating thermal management system will have a significant benefit on the total discharge energy output for electric vehicles that regularly encounter temperatures below -20℃ [7].

Extensive research is being conducted to develop efficient and safe methods of preheating batteries in EVs to maintain them within the optimal operating temperature range of 15℃ to 35℃ [8,9]. These preheating techniques can be classified into two categories: internal heating and external heating, depending on whether the heat source is located inside or outside the battery cell [10]. In laboratory settings, although commonly used internal heating techniques like self-heating and current excitation heating can improve the performance of individual cells or batteries at low temperatures, they also carry the risk of causing damage [11,12]. Further research is needed to evaluate their suitability for battery packs and electric vehicles as a whole. External heating methods based on the battery thermal management system use devices from the outside to transfer heat through heat transfer media such as air, liquid, Phase Change Material (PCM), and electro thermal plates/films [13]. This article aims to provide practical engineering perspectives and suggestions by briefly reviewing the state-of-the-art low-temperature external preheating techniques for LIB packs in electric vehicles.

External preheating system

In this section, external preheating technologies are divided into five categories: Air-based preheating, liquid-based preheating, PCMbased preheating, electro thermal element preheating, and hybrid preheating methods. PCM preheating techniques, which can alter a material’s state of matter and absorb or release a large amount of latent heat, are currently popular research topics. These techniques have the advantage of temperature uniformity and simple design of the BTMS. Great efforts have been made to increase enhance the low thermal conductivity and volumetric energy density of PCM in the storage system [14,15]. Hybrid approaches, incorporating a battery pack with PCM and heating film, have shown enhanced preheating performance by optimizing heating film power, power variance, cell spacing, and PCM thickness [16]. A thermal energy storage setup featuring electric heaters, cooling pipes, and paraffin PCM in its core module has been developed for rapid-charging electric city buses. During charging, electric resistance heaters are employed and directly embedded within the PCM to capture and store its heat [17]. A forced air convection heating system centered on a PCM battery module has been constructed, simultaneously ensuring heating speed and temperature uniformity across the battery pack through multiple fans and a closedloop configuration [18]. However, most studies on PCM-based preheating are still in the stage of complex laboratory research or simulation prototypes and have not been conducted on a real vehicle yet. Therefore, this review briefly describes the preheating methods used in best-selling or prototype EVs, which include various preheating devices and the control strategy of mainstream battery preheating techniques.

Air-based preheating: Air preheating warms the battery pack either through an external heat source or by the on-board air conditioner, using air as the medium for heat exchange. Depending on the presence of a heating device, this technology can be classified as passive (natural convection) or active (forced air convection) preheating. Passive air preheating performance, which is determined by pack geometry, exposed surfaces, and cell placement, is suitable for low-energy-density batteries like lead-acid batteries. An active preheating system, which includes a fan and a heater to drive convective air for transferring thermal energy, is necessary for highenergy- density batteries like LIBs [19]. Air-based preheating offers several benefits, such as low cost, structural simplicity, and easy maintenance. This method has been applied in early-stage EVs, like the Honda Insight and Toyota Prius, which use forced cabin air to help regulate battery temperature [20]. However, they suffer from the low heat capacity of air and temperature inconsistencies, which are why they have been deployed less in recent vehicles.

In summary, the air-based preheating technique still holds significant potential and value in specific applications because of its simplicity, cost-effectiveness, and environmental friendliness. Novel structural design of the air-based preheating battery pack and corresponding heating strategies should be carefully considered to meet the desired requirements for practical applications of EVs. In addition, future research should also focus on the noise generated by fans, which may affect BTMS’s reliability and comfort of the driver and passengers.

Liquid-based preheating: A liquid-based preheating system, typically integrated with cooling BTMS, heats the liquid coolant in battery packs with higher thermal conductivity and convective heat transfer rates. Compared with air, this system leads to a more uniform temperature distribution and increased heating efficiency. Despite the complexity and higher costs associated with liquid-based systems, their high safety and reliability make them viable and easy to maintain for passenger electric vehicles [19]. Regardless of whether the heating liquid comes into direct contact with the battery, such as immersion liquid heating or non-contact heating through specific components that separate the cells and the coolant, such as dual cooling plates the liquid coolant is usually warmed up by a water heater [21,22]. Automotive water heaters typically include ceramic-based heaters and thin film heaters. The characteristics of each type are analyzed as follows.

Literature Review

Positive Temperature Coefficient (PTC) water heater

Barium titanate-based ceramics with a Positive Temperature Coefficient (PTC) of resistance have become increasingly important due to their use as the main heating element in electric vehicles [23]. The PTC heater offers the advantages such as low thermal resistance, high heat exchange efficiency, and minimal power attenuation over extended periods of use. In current vehicles such as the Volkswagen ID.3, two electric heaters are utilized in electric air conditioners. The vehicle cabin is heated by an air heater, while the battery is heated by a water heater [24,25]. This system comprises a liquid preheating BTMS, a heat exchanger, a pump, and circulation pipes [26]. In the Heating, Ventilation, and Air Conditioning (HVAC) system of EVs, PTC heaters are integrated into the liquid cooling loop as auxiliary devices and controlled by the HVAC system [27]. Heating the power battery through PTC will activate the air conditioning and operate the entire passenger compartment heating system. During the battery charging and heating process, warm air will blow out from the passenger compartment of the electric vehicle, leading to energy diversion [28,29]. This not only results in a waste of heating energy but also contradicts the user's typical driving behavior. In an electric city bus equipped with LiFePO4 battery cells, a modified preheating system featuring three distributed PTC heaters has been implemented [30]. However, the preheating time has not significantly improved when heating to the target temperature of 2℃ at an ambient temperature of -10℃, and using three heaters, each with a maximum power of 8 kW, results in high power consumption. Even worse, the PTC power released by the HVAC system may vary due to factors like the current water temperature, flow rate, and the power requested by the Hybrid Control Unit (HCU). In case the cold temperature reaches values in which the heat pump loses performance such as dramatically decrease of heating capacity and heating performance coefficient, an PTC heater or the waste heat recovery system are essential components that the BTMS must use [31]. In order to enhance battery longevity, a quick charging protocol has been created that considers the maximum non-harming charging current at low temperatures [32]. This upgraded charging approach, in conjunction with a refined multi-stage heating plan, segments the battery temperature into distinct phases to control the power of PTC heaters. By factoring in temperature-appropriate charging currents as constraints during charging in low-temperature environments, this approach averts lithium precipitation triggered by excessive charging currents without substantially prolonging the charging duration.

Heat pump with PTC heater: When compared to a PTC heater, heat pumps can provide the same amount of heating while consuming less energy, which is crucial for electric vehicles where maximizing driving range is a priority. An electric heater auxiliary to the heat pump air conditioning system can enhance the heating efficiency. In the coolant heating loop, heat pumps have the ability to vary their heating capacity by adjusting compressor speed, allowing for more precise control and better energy management [33]. Tesla has developed a novel rotary valve known as the “octovalve”, featuring eight ports that facilitate coolant circulation across five separate loops.

In the scenario where the ambient temperature drops below -10℃ and solely the battery necessitates heating, the cold coolant from the drive unit is directed towards a liquid-cooled condenser. In this stage, the coolant absorbs more heat from the compressed and hot refrigerant sourced from the compressor before passing through the octovalve to the chiller for a cooling process. Ultimately, the now warmed coolant progresses to the battery loop to provide heat to the battery [34]. Nowadays, accomplished car brands like Mercedes-Benz, BMW, Audi, and Nissan have introduced new EV models equipped with a heat pump system. The Nissan Ariya also utilizes a PTC heater in parallel with the battery pack to improve the heating rate of the long-life coolant circulating from the chiller [35]. Waste heat recovery technology integrated with heat pump air conditioners has been explored as a way to reduce the energy consumption of battery packs under low-temperature working conditions. The cooling circuit of the motor is connected in series to the battery and the water-heated PTC heater through an electronic expansion valve to facilitate rapid battery preheating [36].

High-voltage coolant heater with thin-film heating elements: Another type of water Heater is a High-Voltage Coolant Heater (HVCH) with heating elements made of layered thin-film structures. Using a silver-palladium alloy as a resistive heating layer of only 8 μm thickness, the 7 kW HVCH is highly compact and relatively flattened compared to the PTC heater. It consumes less energy in the preheating process and generates nearly twice the power density as PTC heaters [37]. The serpentine heating layer can be printed on the cover of HVCH instead of the heater body, which is more convenient for clamping during the printing process. In addition, the temperature uniformity in the HVCH can be regulated with the aid of a dual-input port. BorgWarner Inc. has extended the application of HVCH to the fields of hybrid vehicles and electric vehicles as well as proton exchange membrane fuel cell systems [38,39]. Durable screen-printed thick film heating elements submerged in the coolant cabin can quickly provide heat when required by the Battery Management System (BMS). Additionally, the small thermal resistance between the heating element and the coolant enables maximum power efficiency. The minimum temperature applicable to the HVCH available in power variants from 3 to 10 kW is -40℃, which is significantly lower than the operating temperature of the heat pump.

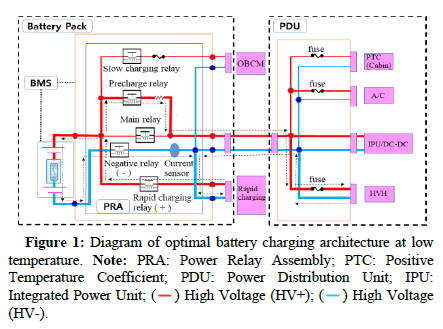

When the battery is fully charged and exposed to cold ambient conditions before the vehicle’s departure, the HVCH is used to preheat the battery and electric drivetrain loop. As a result, the online computational burden of solving a nonlinear program to minimize the total energy consumption of the vehicle has been significantly reduced, requiring only a 1Wh increase in energy consumption over a 60 km driving distance [40]. During the rapid preheating process, the PTC heater and the condenser, which provide warm air for the vehicle cabin, are not activated. This helps to reduce energy consumption. When the electric vehicle is connected for charging before departure, the BMS will safeguard the battery pack’s safety by deactivating the main positive relay of the battery system during the preheating phase, as depicted in Figure 1. Through managing the on/off state of relays on the connection lines of the Onboard Charger Module (OBCM) and DC charging ports, the battery charging system can enable or disable the respective ports. This practice prevents passive charging or discharging of the power battery, circumvents current fluctuations in the BMS during HVCH heating, and upholds a stable system. The heater will run until the battery achieves the target temperature. At that point, the precharge relay will be disengaged, marking the completion of the preheating process.

Discussion

As a more mature technology in passenger EVs, liquid-based preheating offers higher thermal conductivity and heat capacity, despite the necessity of increasing the complexity of the cooling structure design of the battery pack. Various liquid-based preheating devices can be electrically connected in parallel or series to achieve optimal heating efficiency or minimize energy consumption. Additionally, emphasizing the need to optimize the charging strategy at subzero temperatures will be crucial in the future, taking into account variables like current fluctuations that could harm batteries.

Electro thermal element preheating

The electro thermal elements are usually attached to the surface of the battery and heated through electrical-thermal conversion. Electro thermal plate preheating and Peltier-effect preheating, which are used in actual EVs are discussed in this study. Certain EV models, such as the Nissan Leaf with a 24 kWh battery capacity, utilize electro thermal plates for preheating. However, the driving range of the 2012 Nissan Leaf drops substantially in cold weather at -10℃ and is limited to approximately 100 km at speeds of 90 km/h or less. At a constant speed of only 50 km/h, the battery energy use with the heater reaches its lowest value [41,42]. Peltier effect elements have been applied in SAM EVII EVs for precise temperature control during battery preheating [43]. By increasing the amplitude of the electrical current passing through the Peltier element, the rate of temperature rise of cells increase. However, the widespread use of these elements is limited by the high cost of semiconductor materials. Two thermal units, each comprising 12 Peltier thermoelectric modules sandwiched between heat sinks, are utilized for heating the frontal and rear battery boxes. These units warm up the batteries by transferring heat to the air flowing from ambient [44]. Despite this, the average Coefficient-of- Performance (COP) in heating mode is less competitive compared to electric resistance heaters and mechanical heat pumps..

The electro thermal element is easy to install due to its uncomplicated design, which minimally affects the battery housing volume. Nevertheless, managing the temperature of electro thermal plates presents a risk of battery ignition due to overheating, and the Peltier-effect elements’ low COP prolongs the preheating duration if the ambient temperature drops below 0℃. Further research is imperative to comprehensively explore the safety and dependability of electro thermal element preheating methods.

Conclusion

This paper discusses the advanced external preheating strategies utilized by vehicle manufacturers in cold temperatures. While each preheating method has distinct advantages and various applications in research literature, a qualitative comparison can be made based on heating efficiency, temperature consistency, energy consumption, and COP at low temperatures. Most world-renowned automobile brands typically opt for the non-contact liquid-based preheating system with PTC heater or heat pump due to its superior thermal conductivity, safety, and reliability. It is important to recognize that certain preheating devices, like HVCH, rely on external grid energy for power during charging process. Battery preheating does not require its own energy consumption, but the charging strategies must align with the heating control strategy. Hybrid approaches that combines PCM-based with air-based, or electro thermal element preheating techniques, balancing their strengths and weaknesses, holds promise for enhanced preheating performance in real-world vehicle applications.

Acknowledgement

The authors would like to thank the support from the Research Capacity Enhancement Project for Key Construction Discipline of Guangdong Province (2021ZDJS027).

References

- Qi C, Liu ZY, Lin CJ, Hu YZ, Liu DH (2024) Study on the effect of low-temperature cycling on the thermal and gas production behaviors of Ni0.8Co0.1Al0.1/graphite lithium-ion batteries. Appl Therm Eng 247:123054.

- Zhao, LY, Zheng MX, Zhang, JM, Liu H, Li W (2023) Numerical modeling of thermal runaway for low temperature cycling lithium-ion batteries. J Energy Storage 63:107053.

- Ye ZB, Fu XF, Zhou SJ (2024) Research on control strategy of rapid preheating for power battery in electric vehicle at low temperatures. Appl Therm Eng 245:122770.

- Mei W, Jiang L, Liang C, Sun J, Wang Q (2021) Understanding of Li‐plating on graphite electrode: detection, quantification and mechanism revelation. Energy Storage Mater 41:209-221.

- Weisenberger C, Harrison DK, Zhou C, Knoblauch V (2023) Revealing the effects of microstructural changes of graphite anodes during cycling on their lithium intercalation kinetics utilizing operando XRD. Electrochim Acta 461:142629.

- Barcellona S, Piegari L, Villa A (2019) Passive hybrid energy storage system for electric vehicles at very low temperatures. J Energy Storage 25:100833.

- Fly A, Kirkpatrick I, Chen R (2021) Low temperature performance evaluation of electrochemical energy storage technologies. Appl Therm Eng 189: 116750.

- Wang Q, Jiang B, Li B, Yan Y (2016) A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew Sustain Energy Rev 64:106-128.

- Wang Y, Wang L, Li M, Chen Z (2020) A review of key issues for control and management in battery and ultra-capacitor hybrid energy storage systems. Transportation 4:100064.

- Wang Y, Zhang X, Chen Z (2022) Low temperature preheating techniques for Lithium-ion batteries: Recent advances and future challenges. Appl Energ 313:118832.

- Ruan H, Sun B, Zhu T, He X, Su X, et al. (2021) Compound self-heating strategies and multi-objective optimization for lithium-ion batteries at low temperature. Appl Therm Eng 186:116158.

- Wu X, Cui Z, Chen E, Du J (2020) Capacity degradation minimization oriented optimization for the pulse preheating of lithium-ion batteries under low temperature. J Energy Storage 31: 101746.

- Piao N, Gao X, Yang H, Guo Z, Hu G, et al. (2022) Challenges and development of lithium-ion batteries for low temperature environments. eTransportation 11:100145.

- He S, Xiong B, Lei H, Dong K, Khan SA, et al. (2023) Optimization of low-temperature preheating strategy for Li-ion batteries with supercooling phase change materials using response surface method. Int Commun Heat Mass. 142:106635.

- Jaguemont J, Mierlo JV (2020) A comprehensive review of future thermal management systems for battery-electrified vehicles. J Energy Storage 31:101551.

- E JQ, Qin YS, Zhang B, Yin HC, Tan Y (2023) Effects of heating film and phase change material on preheating performance of the lithium-ion battery pack with large capacity under low temperature environment. Energy 284:129280.

- Kraft W, Stahl V, Vetter P (2020) Thermal storage using metallic phase change materials for bus heating-state of the art of electric buses and requirements for the storage system. Energies 13:3023.

- Lv YF, Yang XQ, Zhang GQ, Li XX (2019) Experimental research on the effective heating strategies for a phase change material based power battery module. Int J Heat Mass Tran 128:392-400.

- Wu S, Xiong R, Li H, Nian V, Ma S (2020) The state of the art on preheating lithium-ion batteries in cold weather. J Energy Storage 27:101059.

- Kelly KJ, Mihalie M, Zolot M (2002) Battery usage and thermal performance of the toyota prius and honda insight during chassis dynamometer testing XVII. The Seventeenth Annual Battery Conference on Applications and Advances, Batter Conf Appl Adv Seventeenth Annu 247-252.

- Jiang W, Lyu PZ, Liu XJ, Rao ZH (2024) An immersion flow boiling heat dissipation strategy for efficient battery thermal management in non-steady conditions. Appl Therm Eng 245:122783.

- Wen K, Fu XF, Pei F (2023) Research on the thermal management safety of the fast charging power battery management system. Energy Rep 10:3289-3296.

- Prohinig JM, Reichmann K, Bigl S (2021) The role of SiO2 in semiconducting BaTiO3-based ceramics: Extension of the Jonker model and effect on the electrical properties. Open Ceramics 7:100138.

- Wassiliadis N, Steinsträter M, Schreiber M, Rosner P, Nicoletti L, et al. (2022) Quantifying the state of the art of electric powertrains in battery electric vehicles: Range, efficiency, and lifetime from component to system level of the Volkswagen ID.3. eTransportation 12:100167.

- Liu X, Hong X, Jiang X, Li Y, Xu K (2023) Novel approach for liquid-heating lithium-ion battery pack to shorten low temperature charge time. J Energy Storage 68:107507.

- Gamra KA, Wassiliadis N, Allgauer C, Lienkamp M (2024) Revealing the effect of initial conditions and the potential of self-heating versus active heating on fast-charged lithium-ion batteries. J Energy Storage 84:110968.

- Chen P, Lu Z, Ji L, Li Y (2013) Design of the control scheme of power battery low temperature charging heating based on the real vehicle applications. IEEE Veh Power Propuls Conf (VPPC) 4:105-110.

- Hu X, Zheng Y, Howey DA, Perez H, Foley A, et al (2020) Battery warm-up methodologies at subzero temperatures for automotive applications: Recent advances and perspectives. Prog Energ Combust 77:100806.

- Wang Z, Du C (2021) A comprehensive review on thermal management systems for power lithium-ion batteries. Renew Sust Energ Rev 139:110685.

- Zhu T, Min H, Yu Y (2017) An optimized energy management strategy for preheating vehicle-mounted Li-ion batteries at subzero temperatures. Energies 10(2):243.

- He LG, Jing HD, Zhang Y, Li PP, Gu ZH (2024) Performance research of integrated thermal management system for battery electric vehicles with motor waste heat recovery. J Energy Storage 84:110893.

- Zhang Z, Min H, Yu Y, Cao Q, Li M, et al. (2022) An optimal thermal management system heating control strategy for electric vehicles under low-temperature fast charging conditions. Appl Therm Eng 207:118123.

- Ma Y, Ding H, Liu Y, Gao J (2022) Battery thermal management of intelligent-connected electric vehicles at low temperature based on NMPC. Energy 244:122571.

- Wray A, Ebrahimi K (2022) Octovalve Thermal Management Control for Electric Vehicle. Energies. 15:6118.

- Maiorino A, Cilenti C, Petruzziello F, Aprea C (2024) A review on thermal management of battery packs for electric vehicles. Appl Therm Eng 238:122035.

- Liu X, Zhang F, Zhang Z, Huang Y, Chen L, et al. (2024) A three-heat source segmented heating control strategy based on waste heat recovery technology for electric vehicles. Energ Convers Manage 300:117932.

- Son KJ (2023) Optimal power distribution of high-voltage coolant heater for electric vehicles through electro-thermofluidic. Int J Auto Tech-Kor 24(4):995-1003.

- Stifel T (2021) Optimization and Protection of Traction Batteries with an HV Coolant Heater. ATZ Worldwide 123: 44-47.

- Rios GM, Schirmer J, Gentner C, Kallo J (2020) Efficient thermal management strategies for cold starts of a proton exchange membrane fuel cell system. Appl Energ 279:115813.

- Hamednia A, Forsman J, Murgovski N, Larsson V, Fredriksson J (2023) Computationally efficient approach for preheating of battery electric vehicles before fast charging in cold climates. IFAC PapersOnLine 56(2):6630-6635.

- Laurikko J, Granström R, Haakana A (2013) Realistic estimates of EV range based on extensive laboratory and field tests in Nordic climate conditions. World Electr Veh J 6: 192-203.

- Y Ji, CY Wang (2013) Heating strategies for Li-ion batteries operated from subzero temperatures. Electrochim Acta 107:664-674.

- Kras B, Aebi A (2010) Improvement of low temperature performance of SAM EV-II Li-ion battery pack by applying active thermal management based on Peltier elements. In Proceedings of the 25th World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Shenzhen, China.

- Alaoui C, Salameh ZM (2005) A novel thermal management for electric and hybrid vehicles. IEEE T Veh Technol 54(2):468-576.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi

) High Voltage (HV+); (

) High Voltage (HV+); ( ) High Voltage

(HV-).

) High Voltage

(HV-).