Research Article, J Food Nutr Disor Vol: 8 Issue: 1

Proteolysis of Reduced-Salt Cheddar Cheese as Affected by Casein to Fat Ratio, Rennet, and pH at Drainage

Ali Sheibani1*, Ayyash M2, Vasiljevic T1 and Vijay K Mishra1

1Advanced Food Systems Research Unit, College of Health and Biomedicine, Victoria University, Werribee Campus, PO Box 14428, Melbourne, Australia

2Department of Food Science, College of Food & Agriculture, United Arab Emirates University, Al Ain - United Arab Emirates

*Corresponding Author : Ali Sheibani

Advanced Food Systems Research Unit, College of Health and Biomedicine, Victoria University, Melbourne, Australia

Tel: +61 3 99198130

E-mail: ali.sheibani84@gmail.com

Received: February 15, 2019 Accepted: March 08, 2019 Published: March 18, 2019

Citation: Sheibani A, Ayyash M, Vasiljevic T, Mishra VK (2019) Proteolysis of Reduced-Salt Cheddar Cheese as Affected by Casein to Fat Ratio, Rennet, and pH at Drainage. J Food Nutr Disor 8:1. doi: 10.4172/2324-9323.1000259

Abstract

Effects of change in pH at drainage (6.2, 5.9, and 5.6), rennet concentration (0.1 and 0.3 mL rennet/L of milk) and casein to fat ratio (0.6, 0.7, and 0.8) on proteolytic characteristics of salt-reduced Cheddar cheese were investigated. Chemical composition, lactic acid bacteria and proteolysis were measured. At the same drainage pH, cheeses with C/F ratio 0.6 had significantly higher moisture and ash content compared other ratios. The pH decreased significantly from day 0 (right after pressing) to 120 day and then remained constant. Total LAB growth in cheeses made with 0.3 ml rennet /L was higher at the same C/F ratio and pH at drainage of 6.2. Total plate count at day 180 was significantly higher compared with day 0 (right after pressing). At the same drainage pH, C/F ratio and storage time, water soluble nitrogen contents in cheeses made with 0.3 ml/L rennet were higher compared with 0.1 ml/L. Total free amino acids and trichloroacetic acid-soluble nitrogen contents increased significantly during storage. More hydrophobic peaks appeared as the rennet concentration was increased from 0.1 to 0.3 ml/L. Extra-hydrophobic peptides % in cheese at day 0 and pH at drainage of 5.6, were higher compared to cheese where pH at drainage was 6.2. Increase in C/F ratio and rennet concentration, especially at low pH, showed similar proteolysis as cheese containing 2.5-3% salt.

Keywords: Salt-reduced Cheddar cheese; proteolysis; casein-to-fat ratio; pH at drainage; rennet

Introduction

Proteolysis is the process of breakdown of milk protein mainly casein into smaller polypeptides and amino acids that plays a significant role in development of flavor and texture of Cheddar cheese during ripening process. Factors, such as existent enzymes of milk (plasmin), added coagulants (chymosin) and starter culture accelerate the proteolytic process in Cheddar cheese [1]. The flavor is directly affected by the development of peptides and free amino acids during ripening [2]. A soft texture of cheese is a consequence of the conversion of existing unaffected casein within protein matrix, into polypeptides and smaller water-soluble peptides. However, peptides produced during proteolysis under certain conditions cause bitterness in Cheddar cheese [3,4] reported that the bitterness was high in ovine cheese made with microbial coagulant due to production of hydrophobic peptides. Similar study has been done by Børsting et al. [5] on fat-reduced Cheddar cheese made with different coagulants. Cheddar cheeses made with bovine chymosin showed high bitterness taste. Pollard et al. [6] suggested that enhancement of proteolytic activity in Cheddar cheese decreased the firmness and raised the crumbliness in the cheese. Apart from above mentioned affecting factors, salt (NaCl) content of cheese also influences the proteolysis indirectly. For instance, the higher the salt content, the lower the microbial activity and consequently the lower proteolysis rate and the lower peptide production which in turn impacts the sensory quality of cheese negatively [7]. On the other hand, salt associates with some health issues including hypertension, osteoporosis, and kidney stone and cardiovascular diseases [8]. Therefore, a reduction in daily sodium intake is recommended [9]. Reduction of salt content adversely affects most characteristics of cheese as described by several researchers [10-12]. Likewise, the texture of cheese which is highly affiliated with the rate of proteolysis is influenced by reduction of salt content of cheese [13]. Therefore, decrease in salt content of cheese should be taken into consideration in order to maintain the quality of cheese as well as the health standards. Based on the review of open literature [14] the effect of lowering salt content in Cheddar cheese has been investigated by Sheibani et al. [15] Authors found that Cheddar cheese dry-salted by 1.5% NaCl showed similar properties of control Cheddar cheese (2.5%). Therefore, this current study was designed to investigate several factors on proteolysis of low-salted Cheddar cheeses. It appeared to be lack of information about proteolysis as affected by modification of casein to fat ratio, rennet concentration and pH at drainage step, particularly, when Cheddar cheese with low salt concentration is prepared. The objective of this study was to establish the effect of changes in draining pH, rennet concentration, and casein-to-fat ratio on the extent of proteolysis of salt-reduced Cheddar cheese during storage at 9 ± 0.5°C for 180 days.

Materials and Methods

Experimental design

In the current study, three main factors were adjusted including casein/fat ratio of the milk (0.6, 0.7 and 0.8), pH at drainage (6.2, 5.9 and 5.6) and rennet concentration (0.1 and 0.3 ml per L milk). Thus, eighteen experimental cheeses (3 C/F ratio × 3 pH levels × 2 rennet concentrations) were made in a full factorial design and the code of each experimental cheese is presented in Table 1. The experimental design was also replicated on a separate occasion. For each trial, the chemical composition of the milk (Protein=3.2 g/100 g, Fat=3.8 g/100 g, carbohydrate=4.9 g/100 g, sodium=41 mg/100 g, calcium=117 mg/100 g, pH=6.70) was examined to ensure that no significant variation come from milk composition.

| Factors | Treatment codes | ||

|---|---|---|---|

| pH | C/F ratio1 | Rennet concentration | |

| 6.2 | 0.6 | 0.1 | (6.2/0.6/0.1) |

| 0.3 | (6.2/0.6/0.3) | ||

| 0.7 | 0.1 | (6.2/0.7/0.1) | |

| 0.3 | (6.2/0.7/0.3) | ||

| 0.8 | 0.1 | (6.2/0.8/0.1) | |

| 5.9 | 0.6 | 0.1 | (5.9/0.6/0.1) |

| 0.3 | (5.9/0.6/0.3) | ||

| 0.7 | 0.1 | (5.9/0.7/0.1) | |

| 0.3 | (5.9/0.7/0.3) | ||

| 0.8 | 0.1 | (5.9/0.8/0.1) | |

| 5.6 | 0.6 | 0.1 | (5.6/0.6/0.1) |

| 0.3 | (5.6/0.6/0.3) | ||

| 0.7 | 0.1 | (5.6/0.7/0.1) | |

| 0.3 | (5.6/0.7/0.3) | ||

| 0.8 | 0.1 | (5.6/0.8/0.1) | |

| 0.3 | (5.6/0.8/0.3) |

Table 1: Experimental design.

Cheese making

Cheeses were prepared according to Kosikowski [16] with some modifications. Pasteurized bovine skim milk and cream were obtained from a local supplier (Parmalat, Victoria, Australia) and casein/fat (C/F) ratio was standardised to 0.6, 0.7 or 0.8 followed by homogenisation (HST Homogeniser HL3, Unipulse Pty. Ltd, Victoria, Australia) at 5 × 106 and 2.5 × 107 Pa at 50°C; afterwards, the milk was kept overnight at 4°C. Next day, the milk was transferred to temperature-controlled cheese vats (25 L, Unipulse Pty. Ltd, Victoria, Australia) and tempered at 32°C for 30 min. After addition of 10% calcium chloride solution (2.5 ml per litre of milk), a commercial freeze-dried Cheddar cheese culture consisting of Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris (0.25% (w/v); R-704 Chr. Hansen, Bayswater, Victoria, Australia) was added and allowed to stay for 35 min before a 0.1 or 0.3 ml/L of diluted single strength rennet (CHY-MAX®200 IMCU/mL, Chr. Hansen) was added with rigorous mixing for 1 min. The milk was coagulated within 35- 40 min and the curd (pH 6.48) was cut into 1 cm3 cubes using cheese wire knives. Curds were cooked at 38°C until pH dropped to 6.2, 5.9 and 5.6. Whey was then drained and curds were cheddared at 38°C until pH reached to 5.3. The milled curds were salted with NaCl (1.5% w/w) and mellowed for 10 min. The salted curds were hooped in 2.5 kg capacity molds and pressed at a pressure of 0.0246 kg/cm2 overnight at room temperature. Pressed cheese was vacuum packaged in oxygen barrier bags (Collinsons Pty. Ltd., Fawkner, Australia) using Multivacs vacuum packaging equipment (Multivac Sepp Haggenmuller, Wolfertschwenden, Germany), and then ripened at 9.0 ± 0.5°C for 180 days. Cheeses were unpacked and sampled at day 0 (right after pressing), 60, 120 and 180 of storage and then vacuumpackaged again. All analyses were carried out in duplicates.

Chemical composition

Moisture was determined by the oven-drying method using acid-washed sand (Sigma, St. Louis, Mo.) at 102°C, fat by the Babcock method, protein by the Kjeldahl method, and ash by the muffle furnace method following Association of Official Analytical Chemists methods [17], for pH measurement, 20 g of grated cheese was macerated with 20 mL distilled water, and the pH of the resulting slurry was measured by a digital pH meter (Meter Lab, Pacific Laboratory Products, and Blackburn, Victoria, Australia) after calibration. Total sodium content of cheeses was measured using a multitype inductively coupled plasma atomic emission spectrometer (ICPE-9000; Shimadzu Scientific Instruments (Oceania) Pty. Ltd., Rydalmere, NSW, Australia) according to Ayyash and Shah [18].

Enumeration of total LAB and total plate count

Total lactic acid bacteria growth in cheeses was enumerated by the pour-plating method as described by Mistry and Kasperson [19] with minor modifications. In brief, 11 g of grated cheese and 99 mL sterile distilled water were blended for 2 min in a stomacher-400 laboratory blender (Seward Medical, London, UK). Serial dilutions were prepared in sterilized 0.1% peptone. Total lactic acid bacteria was enumerated on de Man, Rogosa, and Sharpe (MRS) agar (Merck Pty. Ltd., Bayswater, VIC, Australia) and incubated anaerobically using anaerobic jars (Becton Dickinson Microbiology Systems, Sparks, Md., U.S.A.) and gas generating kits (Oxoid) at 37°C for 48 h. Non-starter lactic acid bacteria (NSLAB) growth was enumerated using M17 Agar (Oxoid Ltd., West Heidelberg, VIC, Australia) aerobically at 37°C for 48 h [20].

Proteolysis Assessment

Water soluble nitrogen (WSN)

The water-soluble extract (WSE) of each cheese sample was prepared according to Kuchroo and Fox [21] Briefly, a mixture of cheese and distilled water (1:2) was kept in a 40°C water bath for 60 min followed by centrifugation (Sorvall T6000D, Thermo Scientific) at 4000 × g for 30 min. The resultant slurry was filtered through a 0.45-μm filter (Millipore Corp., Bedford, MA). The total nitrogen in the filtrate extract (3 ml) was determined by the Kjeldahl method [17].

12% Trichloroacetic acid-soluble nitrogen (TCA-SN)

12% Trichloroacetic acid-soluble nitrogen (TCA-SN) was determined in 9 mL filtrate obtained after 5 mL of WSE was mixed with 5 mL of 24% TCA (Sigma) and left overnight followed by centrifugation at 4000×g for 20 min. The total nitrogen in the filtrate was determined by the Kjeldahl method [17].

Measurement of total free amino acids

The total free amino acids (TFAA) concentration in WSE of experimental cheeses was measured by using the Cd-ninhydrin method according to Folkertsma and Fox [22].

Peptides profile by reverse-phase HPLC

The peptide profile of experimental cheeses during ripening was analyzed by RP-HPLC using an analytical column (C18, 250 mm × 4.6 mm, 5 μm; Grace Vydac, Hesperia, CA).The peptide fractions (hydrophilic, hydrophobic and extra-hydrophobic) were calculated according to method of Sadat-Mekmene et al. [23]. Peptides appeared between retention times 2 – 22 min, 22 – 50 min, and 50 – 100 min were considered as hydrophilic (A), hydrophobic (B) and extrahydrophobic (C), respectively. The percentages were calculated according to the following formula:

Statistical Analysis

Due to the expected effect of storage time on Cheddar cheese parameters, full factorial design was applied to carry out the analysis of all parameters at each storage time. The General Linear Model (GLM) was performed to examine the significant effect of pH, C/F ratio and rennet concentration and their interactions at level (P<0.05) at each storage time. Least significant difference (Fisher`s test) was conducted to test the significance between all 18 experimental cheeses at each storage period (P<0.05). Data analysis was carried out using SAS software V9.0.

Results

Chemical composition

The results of chemical composition of the experimental Cheddar cheeses made with different draining pH, C/F ratio and rennet concentrations at day 0 (right after pressing) of storage are presented in Table 2. The probabilities calculated from the analysis of variance (ANOVA) of the data showed that C/F ratio and pH affected the moisture content significantly (P<0.05) (Table 3); whereas, the effect of rennet concentration, two-way interactions (C/F ratio*rennet, C/F ratio*pH, rennet*pH), and three-way interactions (C/F ratio*rennet*pH) was not significant (P>0.05). The higher amount of moisture was retained in cheeses made with pH 6.2 compared with those made with pH 5.9 and 5.6. An opposite trend was observed for salt-in-moisture (S/M) contents. At high C/F ratio used during manufacture process the total solid contents was high to begin with therefore low moisture but higher S/M were noted. The drop in pH at drainage step from 6.2 to 5.6 caused a significant drop in moisture contents (2.0-3.0%) but showed moderate increase in ash contents. Furthermore, at the same pH, cheeses made with C/F ratio 0.6 had lower (P<0.05) moisture content compared with 0.7 and 0.8. As expected, the increase in C/F ratio from 0.6 to 0.8 increased protein and decreased fat contents in cheeses. Protein and fat contents in experimental cheeses affected significantly (P<0.05) by C/F ratio and C/F ratio*pH interaction, and affected insignificantly (P>0.05) by rennet, pH, two-way interaction (C/F ratio*rennet, rennet*pH) and three-way interaction (Table 3). At the same pH and rennet concentration, cheeses made with 0.8 C/F ratio had higher (P<0.05) protein contents compared with other cheeses (Table 2). At the same pH level, fat content in cheeses made with 0.6 C/F ratio was higher (P<0.05) compared with those made with 0.7 and 0.8. Moreover, cheeses made with 0.7 C/F ratio had higher fat content compared with 0.8 C/F ratios.

| pH | C/F ratio1 | Rennet Con. | Moisture% | Protein% | Fat% | Ash% | Sodium3 | S/M %4 |

|---|---|---|---|---|---|---|---|---|

| 6.2 | 0.6 | 0.1 | 36.19 ± 0.24 | 24.18 ± 0.23 | 33.38 ± 0.24 | 2.76 ± 0.01 | 412.2 ± 15.9 | 5.43 ± 0.11 |

| 0.3 | 36.18 ± 0.35 | 23.81 ± 0.11 | 33.63 ± 0.31 | 2.77 ± 0.03 | 406.7 ± 8.5 | 5.52 ± 0.05 | ||

| 0.7 | 0.1 | 35.78 ± 0.20 | 24.65 ± 0.14 | 30.13 ± 0.60 | 2.40 ± 0.03 | 379.9 ± 8.3 | 5.80 ± 0.10 | |

| 0.3 | 36.29 ± 0.16 | 24.51 ± 0.20 | 29.88 ± 0.43 | 2.44 ± 0.09 | 397.3 ± 21.2 | 5.71 ± 0.08 | ||

| 0.8 | 0.1 | 37.06 ± 0.23 | 25.78 ± 0.24 | 30.25 ± 0.48 | 2.61 ± 0.02 | 403.4 ± 11.8 | 5.89 ± 0.12 | |

| 0.3 | 37.11 ± 0.10 | 25.03 ± 0.32 | 29.63 ± 0.83 | 2.40 ± 0.07 | 406.1 ± 17.2 | 5.98 ± 0.17 | ||

| 5.9 | 0.6 | 0.1 | 33.99 ± 0.12 | 24.42 ± 0.30 | 33.88 ± 0.24 | 2.78 ± 0.03 | 407.8 ± 13.3 | 5.70 ± 0.09 |

| 0.3 | 33.69 ± 0.25 | 24.02 ± 0.13 | 34.13 ± 0.24 | 2.79 ± 0.02 | 373.1 ± 9.1 | 5.88 ± 0.06 | ||

| 0.7 | 0.1 | 34.05 ± 0.29 | 24.01 ± 0.25 | 30.75 ± 0.60 | 2.59 ± 0.07 | 389.2 ± 21.1 | 6.09 ± 0.14 | |

| 0.3 | 34.46 ± 0.28 | 24.81 ± 0.45 | 32.13 ± 0.24 | 2.62 ± 0.01 | 414.0 ± 13.6 | 5.91 ± 0.14 | ||

| 0.8 | 0.1 | 35.11 ± 0.17 | 26.91 ± 0.38 | 29.88 ± 0.43 | 2.65 ± 0.06 | 408.6 ± 7.1 | 6.37 ± 0.06 | |

| 0.3 | 34.92 ± 0.12 | 25.71 ± 0.18 | 29.25 ± 0.52 | 2.47 ± 0.08 | 393.0 ± 10.2 | 6.31 ± 0.12 | ||

| 5.6 | 0.6 | 0.1 | 33.75 ± 0.24 | 23.95 ± 0.29 | 34.38 ± 0.24 | 2.83 ± 0.03 | 404.7 ± 19.6 | 5.96 ± 0.10 |

| 0.3 | 33.10 ± 0.27 | 24.10 ± 0.32 | 35.13 ± 0.24 | 2.84 ± 0.02 | 413.5 ± 13.1 | 6.00 ± 0.05 | ||

| 0.7 | 0.1 | 33.89 ± 0.13 | 24.79 ± 0.20 | 31.75 ± 0.32 | 2.58 ± 0.06 | 424.5 ± 12.3 | 6.14 ± 0.07 | |

| 0.3 | 34.07 ± 0.09 | 24.70 ± 0.24 | 31.88 ± 0.52 | 2.56 ± 0.06 | 390.8 ± 11.4 | 6.04 ± 0.05 | ||

| 0.8 | 0.1 | 34.86 ± 0.19 | 25.37 ± 0.33 | 28.63 ± 0.52 | 2.46 ± 0.05 | 411.3 ± 4.9 | 6.36 ± 0.12 | |

| 0.3 | 34.64 ± 0.10 | 25.39 ± 0.59 | 29.50 ± 0.54 | 2.37 ± 0.02 | 361.2 ± 7.3 | 6.27 ± 0.14 |

• 2 Values are average of four replicates (mean ± standard error)

• 3 Sodium=Sodium content of cheese (mg/100 g)

• 4 S/M%: salt-in-moisture %

Table 2: Chemical Composition of 18 experimental reduced salt Cheddar cheeses (1.5% w/w of curd) made with different draining pH, C/F ratio, and rennet concentrations at day 0 of storage.

| Source of variation | DF1 | Moisture | Protein | Fat | Ash | LAB2 | NSLAB3 | WSN | TCA-SN | TFAA | pH(m) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Storage | 1 | N/A4 | N/A | N/A | N/A | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 |

| C/F ratio5 | 2 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.403 | 0.639 | 0.021 | 0.0001 | 0.0001 | 0.0001 |

| Rennet | 1 | 0.387 | 0.122 | 0.602 | 0.003 | 0.037 | 0.048 | 0.0001 | 0.0001 | 0.0001 | 0.016 |

| C/F ratio*Rennet | 2 | 0.122 | 0.059 | 0.055 | 0.0001 | 0.481 | 0.005 | 0.381 | 0.119 | 0.0001 | 0.605 |

| pH(d) | 2 | 0.0001 | 0.143 | 0.356 | 0.298 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.261 |

| C/F ratio*pH(d) | 4 | 0.381 | 0.039 | 0.0001 | 0.004 | 0.771 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.044 |

| Rennet*pH(d) | 2 | 0.676 | 0.407 | 0.069 | 0.166 | 0.044 | 0.527 | 0.0001 | 0.251 | 0.0001 | 0.037 |

| C/F ratio*Rennet*pH(d) | 4 | 0.602 | 0.162 | 0.089 | 0.045 | 0.040 | 0.0001 | 0.0001 | 0.002 | 0.0001 | 0.407 |

2 LAB=lactic acid bacteria growth

3 NSLAB=Non-starter lactic acid bacteria growth

4 N/A=Not applicable

5 C/F ratio=Casein-to-fat ratio

(d) pH at drainage

(m) Measured pH during storage

Table 3: Calculated probabilities of the analysis of variance.

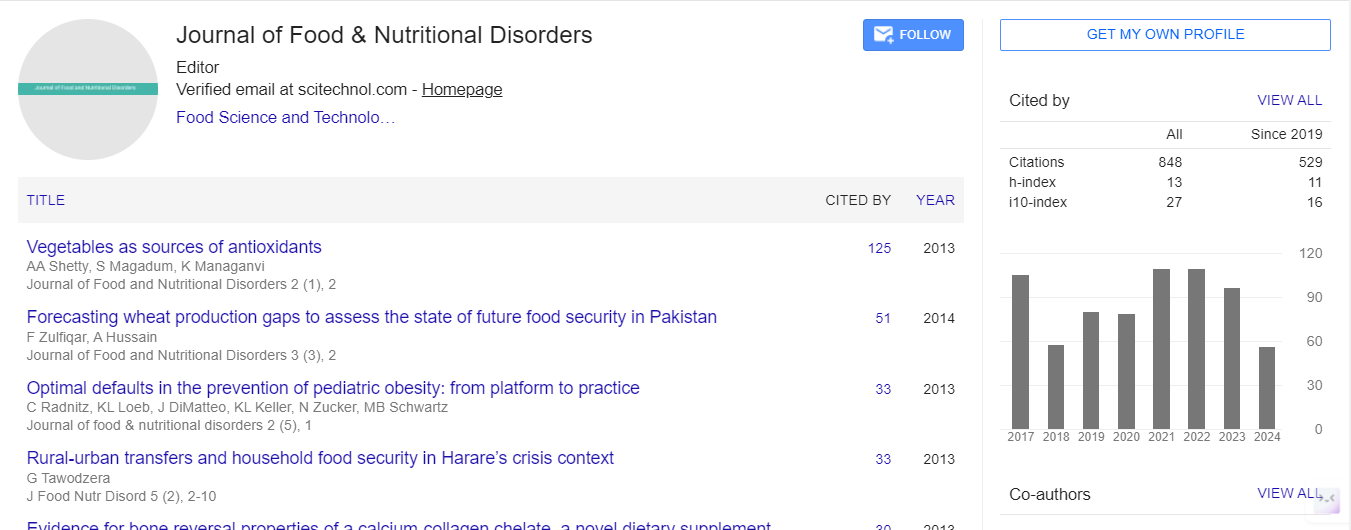

ANOVA showed that C/F ratio, rennet concentration, twoway interactions (C/F ratio*rennet and C/F ratio*pH), three-way interactions had significant (P<0.05) effect on ash content (Table 3). The ash contents in cheeses made with 0.6 C/F ratios were higher (P<0.05) compared with other cheeses at the same pH level. Sodium content of cheeses ranged from 360 to 425 mg/100 g (Table 2), which is lower than the recommended value of 460–920 mg of sodium per day by Anonymous (2007) and NHMRC (2013). The slight difference among sodium content of cheeses can be due to the changes in total solid content of cheese affects the salt-in-moisture content [24] pH of all experimental cheeses showed decreasing trend during the storage (Figure 1). This trend is more notable in cheeses made with lower pH at drainage.

Enumeration of Total LAB and NSLAB

The total LAB and NSLAB growth at day 0 and 180 of the 18 cheeses are shown in Figures 2 and 3, respectively. While NSLAB growth increased the total LAB growth decreased significantly (P<0.05) during storage. The storage time, rennet, pH and three-way interaction (C/F ratio*rennet*pH) significantly (P<0.05) affected total LAB and NSLAB (Table 3). Figure 2 shows that total LAB growth in cheeses made with 0.3 ml/L rennet was higher (P<0.05) than 0.1 ml/L rennet at the same C/F ratio and pH. At pH 5.9 and 5.6, the differences in total LAB growth in cheeses made with 0.1 and 0.3 ml/L rennet were insignificant (P>0.05) at the same C/F ratio and storage period. The increase in rennet concentration increased the amount of the residual rennet in curd causing higher rate of primary proteolysis [25] leading to production of more peptides used as substrates by LAB. As a result, the bacterial growth in cheeses made with 0.3 ml/L rennet was higher compared with 0.1 ml/L rennet. At pH 5.6, regardless of C/F ratio, total LAB growth in cheeses at days 0 was significantly (P<0.05) higher compared with at pH 6.2 and 5.9. Figure 3 presents growth of NSLAB in all experimental cheeses at day 0 and 180. The NSLAB growth at day 180 were significantly (P<0.05) higher compared with day 0. NSLAB growths at day 180 in all cheeses made with 0.3 rennet concentration were significantly (P<0.05) higher. This is due to higher level of peptides, resulting from primary proteolysis, used as substrates by NSLAB [25]. Storage period, rennet, pH, two-way interactions (C/F ratio*rennet, C/F ratio*pH), and threeway interaction (C/F ratio*rennet*pH) affected (P<0.05) the NSLAB growth (Table 3) due to lower salt concentration (1.5% w/w) in cheeses. Salt affects the bacterial growth in cheese by restricting the availability of water [14] 3.4. Proteolysis assessment

Water Soluble Nitrogen of Total Nitrogen

WSN contents of cheeses are shown in Figure 4. ANOVA showed that the main effects of storage period, C/F ratio, rennet, pH, and two-way (C/F ratio*pH, rennet*pH) and three-way interactions (C/F ratio*rennet*pH) significantly (P<0.05) affected WSN content (Table 3). In all experimental cheeses, WSN contents increased significantly (P<0.05) with storage period (Figure 4). At same pH, C/F ratio and storage time, WSN contents in cheeses made with 0.3 rennet were higher (P<0.05) compared with those made with 0.1 ml/L rennet? WSN is an indicator of primary proteolysis taking place in cheese by coagulant residues [26].

12% Trichloroacetic acid-soluble nitrogen of total nitrogen

TCA-SN contents of cheese made with different pH, C/F ratio and rennet concentration and stored at 9 ± 0.5°C for 180 days are displayed in Figure 5. Table 3 presents that the storage, C/F ratio, pH, rennet, two-way interaction (C/F ratio*pH) and three-way interaction (C/F ratio*rennet*pH) affected the TCA-SN contents in all cheeses significantly (P<0.05). Figure 5 shows that TCASN content in all experimental cheeses increased significantly (P<0.05) during storage period. At same pH and storage period, TCA-SN contents increased significantly (P<0.05) as C/F ratio was raised from 0.6 to 0.8.

Total free amino acids

Total free amino acids (TFAA) of all experimental cheeses are presented in Figure 6 as affected by treatments. TFAA content increased significantly (P<0.05) over entire storage period. At 120 and 180 days of storage, TFAA content in all cheeses made with pH 5.6 were higher compared with those made with pH 5.9 and 6.2 (Figure 6). Analysis of variance showed that all factors and their interactions had significant (P<0.05) effect on TFAA (Table 3). Normally TFAA indicates advanced proteolytic activity in cheese which results in more production of small size peptides and amino acids.

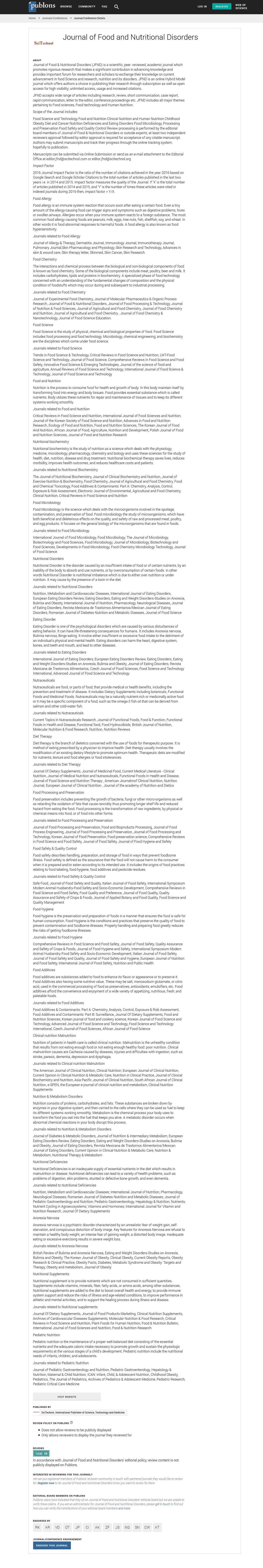

Peptides profile and fractions

The variation in percentages of hydrophilic, hydrophobic, and extra-hydrophobic peptides of the Cheddar cheeses made with different draining pH, C/F ratio, and rennet concentrations are illustrated in Figure 7. The ratios of the hydrophilic, hydrophobic and extra-hydrophobic peptides in factions obtained from all treatment combinations were affected by storage time and rennet concentration (P<0.05). Storage correlated negatively with hydrophilic (-0.619, P<0.001) and hydrophobic (-0.361, P<0.001) and positively with extra-hydrophobic (0.709, P<0.001) peptides in the extract indicating that concentration of extra-hydrophobic peptides increased over time at the expense of hydrophilic peptides. At day 0, hydrophobic peptides were dominant in all cheeses followed by hydrophilic. Afterwards, the percentage of the extra-hydrophobic peptides increased significantly (P<0.05) at the expense of hydrophobic and hydrophilic peptides.

Figure 7: The change in percentages of hydrophilic (blue), hydrophobic (orange), and extra-hydrophobic (gray) peptides of Cheddar cheeses made with different draining pH, C/F ratio, and rennet concentrations during storage period at 9 ± 0.5°C. The circles in the plot represent storage times 0, 60, 120, and 180 days from inside out.

Discussion

Effect of C/F ratio at same pH level and rennet concentration

Milk standardization is the process that maintains the proteinto- fat ratio or casein-to-fat (C/F) ratio fixed. Standardization step in cheese making is very important step to control cheese quality especially of Cheddar cheese. It has been postulated that using standardization process, cheese manufacturers can cope the seasonal variations milk which lead to variation in chemical composition [27]. In order to adjust the C/F ratio, fat content usually is modified. The results of this study show that the variation in C/F ratio had influence on several parameters measured in this study. Increasing the C/F ratio rose moisture content which in turn decreased dry matter of the experimental Cheddars cheeses. Also, the increase in C/F ratio decreased ash and fat contents and increased protein content. These results are in accordance with Fenelon et al. [28] who have studied the impact of reducing fat from 3.33 (C/F ratio=0.75) to 0.54 (C/F ratio=4.71). Authors reported that moisture, and protein contents increased significantly along with fat reduction. Our results also agree with Kumar et al. [29] who reported that moisture content of Feta cheese increased significantly when C/F ratio increased from 0.60 to 0.80. We assume that the reduction in fat content reduced the amount of dry matter which in turn increased the percentages of moisture and protein contents. Due to the influence of C/F ratio on protein moisture contents, C/F ratio indirectly affected the proteolysis in Cheddar cheeses. The experimental cheese that contained higher protein content had generally higher proteolysis rate (TCA). However, the C/F ratio influence on WSN was not clear as TCA which may be attributed that WSN depend on coagulant remain in cheese after drainage. In general, the higher population of LAB over the storage in cheeses made with higher amount of fat (C/F ratio 0.6) is in agreement with Fenelon et al. [28] who reported that the higher starter numbers in the full fat curd was due to comparatively lower syneresis. Increase in fat content of cheese decreases protein content which triggers less protein denaturation and less discharge of moisture [3,30] this provides higher water activity supporting higher bacterial growth (Parente and Cogan 2004). This may be also due to the combined effect of low pH and low salt concentration. C/F ratio showed no significant impact on NSLAB and peptide profile.

Effect of drainage pH at same C/F ratio and rennet concentration

The effect of drainage pH has been studied on different type of cheeses. Studies proved that drainage pH affect the coagulant retention in curd which in turn affects the proteolysis and texture profile of cheeses [30]. Reducing the pH at drainage increase the amount of coagulant remained in curd and then increases the proteolysis rate during ripening [25]. Drainage pH has also influence the calcium content of cheese and thereby affects the textural profile of cheeses [31]. Our results showed that drainage pH had significant influence on proteolysis parameters. WSN, TCA and TFAA rates increased significantly when drainage pH decreased from 6.2 to 5.6. The main reason for these trends may be attributed to the higher amount of coagulant remained in curd during Cheddar cheese processing. According to Fox and McSweeney [1] proteolysis in cheese is divided into three sequential stages: 1) primary stage initiate by remained coagulant in cheese 2) secondary stage starts by action of proteases and peptidases of starter culture in cheese and 3) Advance stage begins with the action of amino peptidases produced by starter culture and non-starter culture bacteria in cheese. Thus, in our results, we postulate that the amount of coagulant remained in cheese was higher and then primary stage start fast and strong which observed in WSN. Consequently, proteolytic enzymes produced by SLAB hydrolyzed effectively on large and intermediate peptides which were obvious in TCA (Figure 4). This allowed for amino peptidases produced by SLAB and NSLAB to hydrolyze small peptides and then produced higher amount of TFAA (Figure 6). Our results are in accordance with those of [32] who found that proteolysis rate increased significantly in cheeses drained at low pH.

It was obvious from our study that the drainage pH had significant effect on moisture content of experimental Cheddar cheeses. The moisture content decreased when drainage pH decreased from 6.2 to 5.6. This may be attributed to the high whey repulsion occurred as a result of acidity increase at the cooking step. Increase in the time between cutting the curd and whey drainage is known to increase acid development enhancing even more whey repulsion out of the curd [33] The impact of drainage pH on ash content in experimental cheeses was significant. The decrease in drainage pH from 6.2 to 5.6 may be increased the solublization of colloidal calcium phosphate from the casein micelle to whey and consequently loss from curd which in turn decreased the total ash content in cheeses [34]. These results are in accordance with Yun et al. [32] that showed that calcium content in mozzarella cheese decreased significantly when pH at whey drain decreased from 6.4 to 6.12. 4.3. Effect of rennet concentration at same C/F ratio and pH level. It has been well stated the significant influence of rennet and/or chymosin during cheese making and ripening. It has been proved that rennet is the main factor that coagulates the milk as first step in cheese making by cleavage the peptide bond (Phe105-Meth106) in κ-casein [35]. Research studies also found that rennet residues in curd have great influence on proteolysis and ripening in cheeses. Upadhyay et al. [25] have reported that the primary stage of proteolysis occurs due to the hydrolytic action of rennet residues in cheese. Rennet residues primarily start hydrolysis of αs1-casein (Phe23-Phe24) with minor or no lysis action on β-casein [1]. The increase in residue concentration of rennet in cheese has been reported to increase the proteolysis rate [25]. In addition to the effect of pH of whey at drainage, rennet concentration added to the milk has been found to impact the amount of rennet residues in cheese which in turn affect the proteolysis. WSN has been reported as indicator for hydrolytic activity of rennet residues [1]. In this study, it was obvious that increasing rennet concentration increased the WSN significantly. These results are in accordance with results of Soodam et al. [36] who reported that pH 4.6-SN/TN increased significantly with increasing Hannilase rennet concentrations in Cheddar cheese. It also agrees with results of Kubiš et al. [37] who found that the pH 4.6-soluble nitrogen contents of Cheddar-type goat’s milk cheeses increased during ripening, and its level was generally proportional to rennet levels. We postulate that the increase in rennet concentration increased the amount of rennet residues in cheese which in turn accelerated the occurrence of primary proteolysis stage by rennet residues [1]. This postulation could explain the significant impact of rennet concentration on peptide profile in our experimental cheeses. In other words, the acceleration in primary proteolysis stage may be occurred due to the increase in rennet concentration provided suitable substrates to proteolytic enzymes produced by SLAB and NSLAB in Cheddar cheese. Our results showed that proteolysis rate (TCA-SN and TFAA) during ripening increased when drainage pH was reduced from 6.2 to 5.6. These results are in accordance with those of [32] who reported that proteolysis in mozzarella cheese increased as an influence by reduction of whey pH at drainage. These results confirm the scientific fact that the amount of rennet residues in curd increases as pH of whey decrease at the time of drainage [25].

Effect of storage time

The effect of time during storage is well stated and observed by extensive studies. During storage, several biochemical changes occur due to several hydrolytic activities including proteolysis, lipolysis and glycolysis. Several factors influence the rate of hydrolytic activities during storage time [1,37]. The results of this study have confirmed the same fact that storage time affected the proteolysis parameters significantly. WSN, TCA-SN and TFAA increased significantly during storage time regardless to changes in other factors including; C/F ratio, drainage pH and rennet concentration. These results are in accordance with results of several studies [38-40]. This trend of increase in WSN, TCA-SN and TFAA may be attributed to proteolytic agents in Cheddar cheeses [1,41-43]. The trends peptide profile may be attributed to the initial proteolytic activities of rennet residues in cheeses and proteinase and peptidases of NSLAB Storage time played major role in changes of peptide profile occurred in Cheddar cheeses [44,45]. Our results showed that hydrophobic peptides were dominant during storage time of all experimental cheeses. In general, hydrophilic peptides decreased significantly whilst hydrophobic and extra-hydrophobic increased (Figure 7). Hydrophilic peptides decreased significantly from 0 day to 60 day of storage and then kept generally constant with prolong of Cheddar cheeses [46]. These trends of peptide profile may be attributed to the initial proteolytic activities of rennet residues in cheeses and proteinase and peptidases of NSLAB.

Effect of interactions

In general, analysis of variance showed that the interaction between factors influenced proteolysis parameters of Cheddar cheese significantly. Indeed, the interpretations of the influence of interactions are not straightforward. However, the interaction effect between rennet concentration and drainage pH was obvious in WSN and TFAA. Our results showed that the increase in rennet concentration increased WSN whereas this increase was more obvious when drainage pH decreased from 6.2 to 5.6. This implies that the amount of rennet residues increased when drainage pH decreased. This hypothesis has been reported by Yun et al. [32]. Who found that proteolysis rate increased when whey pH of mozzarella cheese decreased?

Conclusion

Moisture and ash content of cheeses made with C/F ratio 0.6 were significantly higher compared to other ratios at the same drainage pH. Increase in C/F ratio during manufacture process caused an increase in total solid contents; therefore, the moisture contents decreased which led to increase in S/M. Proteolysis in salt-reduced Cheddar cheese increased when C/F ratio and rennet concentration levels were increased for all levels of pH at drainage. Increase in C/F ratio and rennet concentration, especially at low pH, showed similar proteolysis for cheese containing salt concentration of 2.5%-3% (control). Also, Hydrophilic, hydrophobic and extra-hydrophobic peptide profiles followed similar trend to standard salt concentration. More hydrophobic peptides were produced as a result of increase in rennet concentration over the storage period. In addition to the benefits of low salt intake, higher amount of peptides in low salt cheese Cheddar may have health benefits which need further investigation.

References

- Fox PF, McSweeney PLH (1996) Proteolysis in cheese during ripening. Food Reviews International 12: 457-509.

- Sousa MJ, Ardö Y, McSweeney PLH (2001) Advances in the study of proteolysis during cheese ripening. Int Dairy J 11: 327-345.

- Fox PF, McSweeney PLH, Cogan TM, Guinee TP (2004) Cheese chemistry, physics, microbiology 1: 1069 London, New York.

- Agboola S, Chen S, Zhao J (2004) Formation of bitter peptides during ripening of ovine milk cheese made with different coagulants. Lait 84: 567-578.

- Børsting MW, Qvist KB, Rasmussen M, Vindeløv J, Vogensen FK (2012) Impact of selected coagulants and starters on primary proteolysis and amino acid release related to bitterness and structure of reduced-fat Cheddar cheese. Dairy Sci Tech 92: 593-612.

- Pollard A, Sherkat F, Seuret MG, Halmos AL (2003) Textural changes of natural cheddar cheese during the maturation process. J Food Sci 68: 2011-2016.

- Guinee TP (2004) Salting and the role of salt in cheese. Int J Dairy Technology 57: 99-109.

- Turk MW, Tuite PK, Burke LE (2009) Cardiac health: Primary prevention of heart disease in women. Nursing Clinics of North America 44: 315-325.

- Anonymous (2007) Reducing salt intake in populations. World Health Organization, Paris, France WHO Press.

- Singh TK, Cadwallader KR (2008) Cheese in Dairy Processing and Quality Assurance. 273-307 Iowa US: Willey-Blackwell.

- Fox PF (1987) Significance of salt in cheese ripening. Dairy Industries International 52: 19-22.

- Guinee TP, Fox PF (2004) Salt in cheese: Physical, chemical and biological aspects. In: Cheese: Chemistry, physics and microbiology 207-259 Elsevier Academic Press, London, UK.

- Wick C, Nienaber U, Anggraeni O, Shellhammer TH, Courtney PD (2004) Texture proteolysis and viable lactic acid bacteria in commercial Cheddar cheeses treated with high pressure. J Dairy Res 71: 107-115.

- Sheibani A, Mishra V, Stojanovska L, Ayyash M (2013) Salt in cheese: Health issues. Reduction, Replacement and Release 397-418.

- Sheibani A, Ayyash MM, Shah NP, Mishra VK (2015) The effects of salt reduction on characteristics of hard type cheese made using high proteolytic starter culture. Int Food Res J 22: 2452-2459.

- Kosikowski F (1977) Cheddar cheese and related types. Cheese and Fermented Milk Foods 228-260

- AOAC International (1995) Official methods of analysis of AOAC International. Arlington, VA, USA.

- Ayyash MM, Shah NP (2010) Effect of partial substitution of NaCl with KCl on Halloumi cheese during storage: Chemical composition, lactic bacterial count, and organic acids production. Journal of Food Science 75: 525-529.

- Mistry VV, Kasperson KM (1998) Influence of salt on the quality of reduced fat cheddar cheese. J Dairy Sci 81: 1214-1221.

- Jordan KN, Cogan TM (1993) Identification and growth of non-starter lactic acid bacteria in Irish cheddar cheese. Irish Journal of Agricultural and Food Research 32: 47-55.

- Kuchroo CN, Fox PF (1982) Soluble nitrogen in Cheddar cheese: Comparison of extraction procedures. Milchwissenschaft 53: 262-269.

- Folkertsma B, Fox PF (1992) Use of the Cd-ninhydrin reagent to assess proteolysis in cheese during ripening. J Dairy Research 59: 217-224.

- Sadat-Mekmene L, Richoux R, Aubert-Frogerais, L, Madec MN, Corre C (2013) Lactobacillus helveticus as a tool to change proteolysis and functionality in Swiss-type cheeses. J Dairy Sci 96: 1455-1470.

- Fox PF, Guinee TP, Cogan TM, McSweeney PLH (2000) Fundamentals of Cheese Science. Aspen Publishers, Maryland, USA.

- Upadhyay VK, McSweeney PLH, Magboul AAA, Fox PF (2004) Proteolysis in cheese during ripening. In: Cheese: Chemistry, physics, microbiology. General Aspects 391-433.

- McSweeney PLH, Fox PF (1997) Chemical methods for the characterization of proteolysis in cheese during ripening. Dairy Sci Tech 77: 41-76.

- Walker GP, Williams R, Doyle PT, Dunshea FR (2007) Seasonal variation in milk production and cheese yield from commercial dairy farms located in Northern Victoria is associated with pasture and grazing management and supplementary feeding practices. Australian J Experimental Agriculture 47: 509-524.

- Fenelon MA, O'Connor P, Guinee TP (2000) The effect of fat content on the microbiology and proteolysis in cheddar cheese during ripening. J Dairy Science 83: 2173-2183.

- Kumar S, Kanawjia SK, Kumar S (2011) The effect of varying casein/fat ratio on physicochemical and sensory qualities of Feta-type cheese made using buffalo milk. Int J of Dairy Tech 64: 380-385.

- Lawrence RC, Gilles J, Creamer LK, Crow VL, Heap HA, Honoré CG (2004) Cheddar Cheese and Related Dry-Salted Cheese Varieties: 1-38.

- Lucey JA, Fox PF (1993) Importance of Calcium and Phosphate in Cheese Manufacture: A Review. J Dairy Science 76: 1714-1724.

- Yun JJ, Barbano DM, Kindstedt PS, Larose KL (1995) Mozzarella cheese: Impact of whey ph at draining on chemical composition, proteolysis, and functional properties. J Dairy Science 78: 1-7.

- Tunick MH, Guinee TP, Van Hekken DL, Beresford TP, Malin EL (2007) Effect of whey drainage pH on composition, rheology, and melting properties of reduced-fat Cheddar cheese. Milchwissenschaft, 62: 443-446.

- Roefs SPFM, Walstra P, Dalgleish DG, Horne DS (1985) Preliminary note on the change in casein micelles caused by acidification. Netherlands Milk and Dairy Journal 39: 119-122.

- Crabbe MJ C (2004) Rennets: General and Molecular Aspects. In: Cheese: Chemistry, Physics and Microbiology 19-45 London, UK: Academic Press.

- Soodam K, Ong L, Powell IB, Kentish SE, Gras SL (2015) Effect of rennet on the composition, proteolysis and microstructure of reduced-fat Cheddar cheese during ripening. Dairy Sci Tech 95: 665-686.

- Kubiš I, Sousa MJ, Walsh-O'Grady D, Kelly AL, McSweeney PLH (2001) Proteolysis in Cheddar-type cheese made from goat's milk. Milchwissenschaft 56: 557-560.

- Belitz HD, Kaiser, KP (1993) Monitoring Cheddar cheese ripening by chemical indices of proteolysis - 3. Identification of several high-molecular mass peptides. Zeitschrift für Lebensmittel-Untersuchung und-Forschung, 197: 118-122.

- Kaiser KP, Belitz HD, Fritsch RJ (1992) Monitoring Cheddar cheese ripening by chemical indices of proteolysis - 2. Peptide mapping of casein fragments by reverse-phase high-performance liquid chromatography. Zeitschrift für Lebensmittel-Untersuchung und-Forschung 195: 8-14.

- Anonymous (2007) Reducing salt intake in populations. World Health Organization, Paris, France WHO Press.

- J Law, Fitzgerald GF, Daly C (1983) Proteolysis and flavour development in Cheddar cheese. Aust J Dairy Technol 38: 59-65.

- Ayyash MM, Shah NP (2011) Proteolysis of low-moisture Mozzarella cheese as affected by substitution of NaCl with KCl. Journal of Dairy Science 94: 3769-3777.

- Kosikowski F (1977) Cheddar cheese and related types. Cheese and Fermented Milk Foods 228-260

- Lawrence RC, Creamer LK, Gilles J (1987) Texture development during cheese ripening. Journal of Food Science 49: 1098-1101.

- NHMRC (2013) Australian Dietary Guidelines. Canberra: National Health and Medical Research Council.

- Parente E, Cogan TM (2004) Starter cultures: General aspects. In: Cheese: Chemistry, Physics and Microbiology. Academic Press

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi