Opinion Article, J Food Nutr Disor Vol: 12 Issue: 2

Processing Techniques on Microbial Safety and Quality of Food Products

Navvaro Cartel*

Department of Nutrition Cancer, Allegheny General Hospital, Pittsburgh, Pennsylvania, USA

*Corresponding Author: Navvaro cartel

Department of Nutrition Cancer

Allegheny General Hospital, Pittsburgh

Pennsylvania, USA

E-mail: cartel4@yahoo.com

Received date: 27 March, 2023, Manuscript No. JFND-23-99018;

Editor assigned date: 31 March, 2023, Pre QC No. JFND-23-99018(PQ);

Reviewed date: 17 April, 2023, QC No. JFND-23-99018;

Revised date: 27 April, 2023, Manuscript No: JFND-23-99018(R);

Published date: 01 May, 2023, DOI: 10.35248/ 2324-9323.100348.

Citation: Cartel N (2023) Processing Techniques on Microbial Safety and Quality of Food Products. J Food Nutr Disor 12:2.

Description

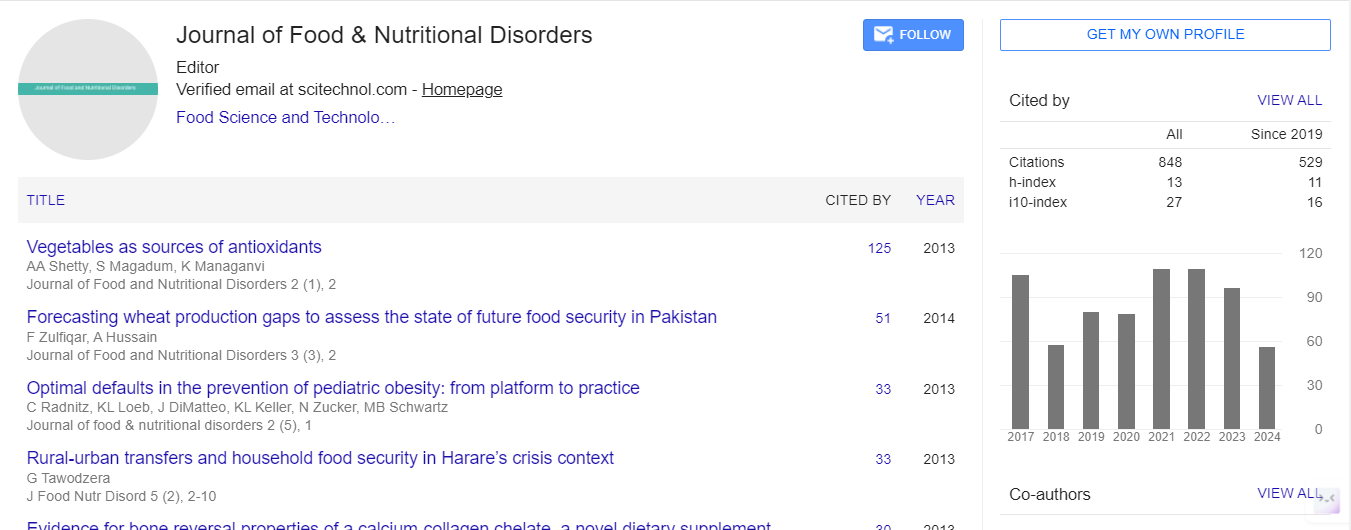

Food safety and quality are paramount concerns for consumers and regulatory bodies worldwide. Microbial contamination poses a significant risk to the safety and shelf life of food products. Therefore, implementing appropriate processing techniques is essential to ensure microbial safety and maintain high-quality standards. This essay explores various processing techniques employed in the food industry to enhance microbial safety and preserve the quality of food products.

Thermal processing is a widely used technique to eliminate or reduce microbial populations in food products. Processes such as pasteurization and sterilization involve applying heat to destroy pathogens, spoilage organisms, and enzymes. Pasteurization is commonly used in the dairy industry to eliminate harmful bacteria, while sterilization is employed for canned foods. Proper temperature and time parameters must be maintained to achieve microbial safety without compromising food quality. High-pressure processing is an emerging technique that uses hydrostatic pressure to inactivate microorganisms. This non-thermal process can extend the shelf life of food products while preserving their sensory and nutritional attributes. HPP is particularly effective against pathogens like Listeria monocytogenes and Escherichia coli, making it suitable for ready-toeat foods, juices, and seafood. Food irradiation involves exposing food products to ionizing radiation to control microbial pathogens. It disrupts the DNA of microorganisms, rendering them unable to multiply. Irradiation is approved for use in various products, including spices, fruits, and vegetables. It effectively eliminates bacteria, viruses, and parasites without compromising nutritional content or sensory qualities. However, consumer acceptance and regulatory concerns have limited its widespread implementation. Modified atmosphere packaging alters the composition of the surrounding atmosphere to inhibit microbial growth and prolong shelf life. It involves replacing atmospheric air with gases like nitrogen, carbon dioxide, or a combination thereof. By reducing oxygen levels, MAP hinders the growth of aerobic spoilage microorganisms. Additionally, it can slow down enzymatic reactions and oxidative processes, maintaining the quality of perishable foods such as meats, fruits, and vegetables. Fermentation is an ancient technique that utilizes microorganisms to transform food substrates, improving their safety, flavor, and nutritional properties. Microbes like bacteria, yeasts, and molds are intentionally added to initiate the fermentation process. This technique is commonly used in the production of fermented dairy products, sauerkraut, kimchi, and sourdough bread. The acidification and production of antimicrobial compounds during fermentation inhibit the growth of pathogenic and spoilage microorganisms.

Chemical preservatives play a vital role in preventing microbial growth and extending the shelf life of food products. Common preservatives include organic acids (e.g., acetic acid), salts (e.g., sodium nitrite), and antimicrobial agents (e.g., nisin). These compounds inhibit the growth of bacteria, yeasts, and molds, ensuring the safety and quality of various food items such as meat products, bakery goods, and beverages. However, it is important to regulate the levels of preservatives to avoid negative health impacts. Proper cleaning and sanitization practices are essential in maintaining microbial safety in food processing facilities. Effective cleaning removes organic matter that can harbor microorganisms, while sanitization involves the use of antimicrobial agents to kill or reduce microbial populations on food contact surfaces. Cleaning and sanitization protocols should be strictly followed to prevent crosscontamination and ensure the production of safe, high-quality food products.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi