Research Article, J Fashion Technol Textile Eng S Vol: 0 Issue: 3

Moisture Management Evaluation in Double Face Knitted Fabrics with Different Kind of Constructions and Fibers

Fernando Barros de Vasconcelos1, Lara Melo Monteiro de Barros1, Camilla Borelli1* and Fernanda Gomes de Vasconcelos2

1University center FEI, Brazil

2Interface Engineering, Brazil

*Corresponding Author : Camilla Borelli

Professor in the Department of Textile Engineering at the Center University of FEI, Av. Humberto de Alencar Castelo Branco, 3972, Brazil

Tel: + (011) 43532900

E-mail: cborelli@fei.edu.br

Received: October 04, 2017 Accepted: November 07, 2017 Published: November 12, 2017

Citation: de Vasconcelos FB, de Barros LMM, Borelli C, de Vasconcelos FG (2017) Moisture Management Evaluation in Double Face Knitted Fabrics with Different Kind of Constructions and Fibers . J Fashion Technol Textile Eng S3:009. doi:10.4173/2329-9568.S3-009

Abstract

When someone plays sports, whether a professional athlete or just a sports lover, is desirable feel comfortable, especially with apparel. This comfort is related to sweat that evaporates or that stay retained in fabric, which has influence body’s thermoregulation and in keeping the fabric dry even during the exercises. Based on this principle, this work had as objective to evaluate moisture management performance in double face knitting with different constructions (swiss piquet and double face pique) and fibers (cotton, polyamide and polyester) using Moisture Management Tester (MMT) to the evaluation. Results shows that double face constructions with different absorption potential fibers in both faces presented more satisfying results confirming hypotheses on the subject.

Keywords: Moisture management; Comfort; MMT

Introduction

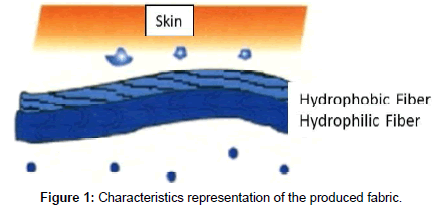

In this study, were produced double face knitting fabrics with fibers that have different hydrophilicity and has sweat absorbing characteristics aiming to create a comfort sensation without wetting or soaking. Its construction principle is shown in Figure 1.

According to Slater et al. [1], comfort, being a fundamental necessity for consumers, is defined as a pleasant state that starts from the physiological, psychological and physical harmony between human and environment. Literature classifies comfort subdivided into three spheres: aesthetic comfort, thermo-physiological comfort and touch comfort. Aesthetic comfort is based on subjective feelings and revolves around fashion trends that have directly influence customer preferences, while touch comfort is related to the mechanical interaction between clothing and human body.

In other hand, thermo-physiological comfort is related to fabrics capacity to maintain the thermal balance between the human body and the environment. Comfort in clothing is related to sweat that evaporates or that stay retained in fabric, which has influence body’s thermoregulation and in keeping the fabric dry even during the exercises.

One of the factors that most influence comfort is fibers. In this study were chosen three fibers: cotton, polyamide and polyester. Cotton has the characteristics of greater moisture absorption, better performance and pleasant touch. Polyamide is a thermoplastic polymer characterized by medium moisture absorption, pleasant touch and quick drying. Polyester being hydrophobic, has low moisture absorption providing to the fabric a quickly drying. The disadvantage of polyester compared to polyamide is the rougher touch and little perspiration.

Objectives

This study had as objective to evaluate moisture management performance in double face knitting with different constructions (swiss piquet and double face pique) and fibers (cotton, polyamide and polyester) using Moisture Management Tester (MMT) to evaluation.

Comfort

Comfort can be defined as a state of physical and mental harmony with the environment based on the absence of any uncomfortable feeling.

Comfort is a very important aspect to be evaluated, especially in relation to sports clothing, where the user, besides exercising a lot, also perspires. Comfort not only affects the athlete's well-being, but also their performance and efficiency.

Moisture generated by human body, known as sweating, is the most effective way to control the increase in body temperature generated by physical activity or external conditions and has a significant influence on human perceptions of thermal comfort. In the first phase of transpiration body generates moisture in a vapor form, condensing, in a second phase, in liquid form.

Liquid generated on body surface (sweat) will have to be eliminated in order to achieve a good level of comfort. Clothing being a natural obstacle to this processes, should minimize this effect by using appropriate fabrics fibers, yarns, construction and finishes [2].

Thus, the management of this moisture constitutes an important point in the definition of main parameters related to textiles comfort. Currently there are in market fabrics with moisture management, in this case, sweat, to disperse it in the environment and keep clothes dry even during physical activities.

According to Nanligoz et al. [3] moisture management depends on textiles properties as liquid resistance, liquid repellence, liquid absorption, capillarity on fibers and yarns, as well as fabric geometry and the internal structure of materials.

Microfibers

Microfibers are multifilament synthetic yarns with individual filaments extremely thin (≤ 1 dtex), which has its yarn count described in dtex, which means a certain weight (grams) in 10 thousand meters of yarn.

The thickness of the fiber can be perceived when compared to other fibers, for example, the microfiber fiber is three times thinner than cotton and 60 times thinner than a human hair. Since microfibers are characterized by being much thinner than conventional fibers, very important variations occur which affect the properties of fibers, yarns and fabrics [4].

From fabrics point of view there are several interesting points in microfiber articles, such as the greater porosity that allows greater and faster moisture transport, greater thermal insulation, greater impermeability to water and wind, among the others. A comparative illustration of some of these phenomena is in the physical properties of fibers in capillary transport and moisture absorption. Within their applications, sporting uniforms stand out as they help to prevent perspiration from accumulating in the fabric.

Double face knitting

Based on the results of the Hohenstein Institute research, the first double-sided fabrics were developed in the early 1980s combining natural (cotton) and synthetic (polypropylene) fibers into two distinct layers. In that decade, an Austrian underwear company along with the Institute developed double-faced clothing for the Austrian women's team to compete at the Winter Olympics in Lake Placid. In this development, the synthetic fibers used in the inside part had the function of transporting fast and effective transpiration of the skin away from the body while the exterior of the garment was cotton to ensure a good buffering effect and moisture evaporation.

Combined in this way these two materials offer significant improvement in comfort, thanks to best transport of sweat, which results in a sensation of dry body, besides the faster drying of the material. Following the positive response from the Olympic athletes, the "Double Sided Transtex" was launched in market for amateur athletes (Figure 2).

The concept of double face fabrics still used today to ensure a better comfort of sports clothing. With the evolution of microfibers, these fabrics are generally produced with hydrophobic fiber in the interior and hydrophobic fiber, but microfiber i.e., with high capillarity, on the outer face.

Among the most common double face knitting construction is Pique, the two most known types being double face Pique and Swiss Pique also known as French Pique.

The Swiss Pique (French) is chosen when it is desired to produce a double face article, but this characteristic does not mean that the fabric has two totally different sides, having the possibility of being reversible. This ligament makes it possible to have on the right side of the fabric one kind of yarn while on the other side there are two kinds of yarn (Figure 3a).

Double face Pique provides a hive (lozenge) appearance on the inner side of the fabric, due to the slope of the knitting and presents totally different threads on both sides (Figure 4).

Moisture Management Tester MMT

In order to reproduce the diffusion of sweat generated by human body and its behavior on fabric surfaces (inner and outer), an instrument was developed combined with a test method called Moisture Management Tester (MMT) created by SDL Atlas, identified in the Figure 5 [5].

MMT is composed of two concentric sensors, bottom and top. As can be seen in Figure 6, the fabric to be tested is placed between sensors so that the side that will contact the human skin is in contact with the upper sensor, so turned upwards, in order to study the behavior this side of the fabric [6]. The opposite side simulates the behavior on the outer side of the fabric, which consequently will contact the external air.

According to Borelli et al. [7] the principle lies in measuring changes in electrical conductivity through contact with the fabric. It is performed during the transport of moisture between the two surfaces. The value of this change depends on two factors: the components present in the water as well as the water content in the fabric. Since the components present in the water are fixed, the value of the electric resistance change is based on the water content in the test fabric [8].

Through the use of MMT, it is possible to obtain several predetermined results and indexes. The main evaluation parameters provided by the software are expressed by indices shown in the Table 1.

| Indexes | Unit | ||

|---|---|---|---|

| Wetting Time | Top | WTt | S |

| Bottom | WTb | ||

| Abortion Rate | Top | Art | %/s |

| Bottom | Arb | ||

| Maximum Wetted Radius | Top | MWRt | mm |

| Bottom | MWRb | ||

| Spreading Speed | Top | SSt | mm/s |

| Bottom | SSb | ||

| Accumulative One-way Transport Capability | ----- | R | % |

| Overall Moisture Mangement Capability | ----- | OMMC | ---- |

Table 1: Indices obtained in MMT.

MMT can also distinguish different kinds of performance from test fabrics in moisture distribution graphs (Figure 7) showing the diffusion of the liquid on both sides of fabric.

Materials and Methods

For this study were chosen Cotton, polyamide (standard and microfiber) and polyester (standard and microfiber) fibers due to their hydrophilicity and absorption characteristics and the construction double face Pique and Swiss Pique because of their constructions [9,10].

With these defined factors, the combinations were determined for the production of samples, according to the Table 2, considering that the inner face is always in contact with the skin and the outer face is not.

| Construction | Inner face | Outer face |

|---|---|---|

| Double face Pique | PES 167f48 | CO Ne 30/1 |

| PES 167f48 | PES 167f144 (micro) | |

| PA 2X 78f23 | PA 2X 80f68 (micro) | |

| PA 2X 78f23 | CO Ne 30/1 | |

| Swiss Pique | PES 167f48 | CO Ne 30/1 |

| PES 167f48 | PES 167f144 (micro) | |

| PA 2X 78f23 | PA 2X 80f68 (micro) | |

| PA 2X 78f23 | CO Ne 30/1 |

Table 2: Yarns for sample production.

Samples were produced in Mayer machine - OVJA 36, fineness 22 and diameter 30 "changing the construction (Table 3).

| Feeding | LFA (cm/lap) | Yarn Speed (m/min) | Tension (cN) |

|---|---|---|---|

| Odd (outer yarn) | 991 | 117 | 5 |

| Even (Inner yarn) | 437 | 50 | 2 |

Table 3: Swiss Pique production data.

The first sample produced was Swiss Pique with the following characteristics:

Then the sample with Double Face Pique construction was produced, with the following characteristics:

A cleaning process was carried out according to the following steps:

1. Washing at 90°C during 30 minutes

2. Two warm baths

3. Five cold baths

The washing recipe used for each sample was as follows:

After cleaning, tests were performed on Moisture Management Tester (MMT), with samples prepared according to AATCC Test Method 195-2009: Liquid Moisture Management.

To represent the sweat, a solution of Sodium Chloride with 9 g of NaCl diluted in 1L of distilled water was prepared in order to reach 16 ± 2 mS of the conductivity of the solution.

The evaluation of results was through Minitab software.

Results

Evaluation of samples behavior

Polyester (inner) and Cotton (outer): As a natural fiber, cotton has the property of being hydrophilic, which means that has possibilities of connections with water molecules. Therefore, the water tends to be retained in the fiber structure, which makes it difficult to transport moisture [11].

Moreover, polyester, because it is hydrophobic, has a small absorption when compared to cotton, therefore the moisture transport occurs by capillarity.

As the liquid is dropped on the polyester surface, the double face Pique structure causes the liquid to be quickly transported to the cotton by capillarity [12,13]. Cotton absorbs the liquid not allowing its contact with the user's skin.

In Swiss Pique structure, the same phenomenon happens with the difference of being at a lower intensity, that is, because it does not have the hive effect on the structure, the rupture of the surface tension is slowly, resulting in a more difficult liquid penetration from inner to outer surface [14].

Polyester (inner) and Polyester microfiber (outer): As is known, the polyester absorbs little liquid because of its hydrophobic nature, but in this case, there is a difference in capillarity between the inner and outer face filaments. The liquid is dropped into the standard polyester (inner) and transferred by capillarity to the outer side of the fabric (microfiber polyester) there will be no absorption, ensuring a dry fabric [15,16].

This fact was observed in both structures, but with much greater intensity in the Double face Pique than in the Swiss Pique due, among others factors, to the absence of the hive effect in the structure (Table 4).

| Feeding | LFA (cm/lap) | Yarn Speed (m/min) | Tension (cN) |

|---|---|---|---|

| Odd (outer yarn) | 703 | 86 | 7 |

| Even (Inner yarn) | 948 | 113 | 5 |

Table 4: Double Face Pique production data.

Polyamide (inner) and Cotton (outer): Because the two fibers are hydrophilic and absorb moisture, although polyamide less than cotton, the expected capillary effect was not achieved. This occurs both in the Double Face Pique structure and in the Swiss Pique, where the capillary effect is even smaller [17].

Polyamide (inner) and Polyamide microfiber (outer): Both standard polyamide and polyamide microfiber absorb moisture, so not all of the moisture is transferred out of the fabric, not leaving the inside of the fabric as dry as expected. This characteristic occurs in both structures, Double face Pique and Swiss Pique, but is more distinct in the Swiss Pique due to the lack of the hive effect on the back of the fabric [18].

Indices do MMT

Accumulative one way transport capability (R): Expresses the accumulated moisture difference between the upper (inner) surface and the lower (outer) surface of the fabric.

In the graph of Figure 8 it can be seen that the PA / CO sample failed to achieve the expected capillary effect as the two fibers absorb moisture. In the PA / PA, PES / PES and PES / CO samples there was the expected effect of capillarity at the Double face pique construction, but not at the Swiss Pique, as can be seen in the graph below. The results of PES samples were higher than those with PA (Table 5).

| Recipe | Product | Quantity (g/L) |

|---|---|---|

| CO/PES | Na2CO2 | 1 |

| Detergent (1:10) | 1 | |

| NaOH (36°Be) | 2 | |

| 100% PES | Na2CO2 | 2 |

| Detergent (1:10) | 1 | |

| CO/PA | Na2CO2 | 1 |

| Detergent (1:10) | 1 | |

| NaOH (36°Be) | 1 |

Table 5: Washing recipe.

Overall moisture management capacity (OMMC): This index indicates fabric's ability to manage moisture and considers three aspects of performance:

• Absorption rate on bottom: ARb

• Accumulative one way transport capability: R

• Spreading speed on bottom: SSb

The manual suggests a classification for moisture management capability according to the OMMC indexes, as follows:

• 0 a 0,2 – very poor

• 0,2 a 0,4 – poor

• 0,4 a 0,6 – good

• 0,6 a 0,8 – very good

• 0,8 a 1,0 - excellent

The OMMC indices obtained for tested samples can be visualized in the graph represented in Figure 9.

Thus, it can be verified:

• All fabrics in Swiss pique construction have a behavior classified as poor regardless of fiber.

• In the Double face piquet fabrics the PA / CO shows very poor behavior, the PA / PA good behavior and the PES / CO and PES / PES very good behavior, the latter being slightly higher.

Conclusion

In this study, properties of moisture management in doubleface knitting fabrics with different constructions and combinations of fibers were considered. The Moisture Management Tester (MMT) was used to evaluate moisture transport.

Yarns selected were Cotton, Polyester standard, Polyester microfiber, Polyamide standard and Polyamide microfiber [19].

The results showed that the Double Face Pique had a better result when compared to the Swiss pique due to the hive effect on the back of the fabric, which helps to break the surface tension and facilitates water penetration on the inner side to the outer and also because Swiss pique is not truly a double-sided fabric. The other differences were due to fibers properties.

In PA / PA fabric the results were satisfactory, but inferior to those made with PES [20].

In the PES / PES fabric, the best overall moisture management capacity Index were observed for having on the inner surface a hydrophobic fiber (PES) which guarantees the capillarity of the liquid, while the microfiber of the outer surface is responsible of diffusion of the liquid. On the other hand, the PES / CO fabric in which CO absorbs the liquid to the outer surface also presented good results of overall moisture management capacity Index and Unilateral Transport Index, but in general a little lower than PES / PES.

These results confirm the hypothesis that the best liquid transport behavior would be obtained with:

• Double face construction with hive surface on inner face

• Use of hydrophobic fiber on the inner surface in a standard yarn and a good absorption fiber or a microfiber yarn of hydrophobic fiber on the outer surface.

References

- Slater K (1986). The assessment of confort. Australian textile institute 77: 157-171.

- Das B, Das A, Kothari VK, Fangueiro R, Araujo M (2007) Moisture transmission through textiles part i: processes involved in moisture transmission and the factors at play.

- Nanligoz ES, Coban S, Bahtiyari MI (2010) Comparison of moisture transport properties of the various woven fabrics, Tekstil Ve Komfeksiyon 20: 93-100.

- Guillén JG (2001) Microfibers. Barcelona

- Atlas (2010) Manual Mmt - Moisture management tester

- American association of textiles chemists and colorists

- Borelli C, Bittencourt E, Vasconcelos FB, Gasi F (2013) Assessment of moisture management in textile articles through mmt. Chemical Textile Magazine V: 58-70.

- Fangueiro R, Filgueiras A, Barbosa RAA (2013) Physiological comfort and athlete performance.

- Gasi F, Bitencourt EE, Vasconcelos FB (2010) Comparative study of vapor permeability properties of moisture transport and ultraviolet protection in polyamide 6.6 and polyester knitting with elastane.

- Higgins L, Anand S (2003) Textile Materials And Products For Active Wear And Sportswear.

- Hu J, Li Y, Yeung KW, Wong AWS, Xu W (2005) Moisture management tester: A method to characterize fabric liquid moisture management properties. Text Res J 75: 57-62.

- Martin JRS (2010) Transpiring comfort: Managing fabric functionality and comfort.

- Ozdil N, Supuren G, Ozçelik G, Pruchova J (2009) A Study on the moisture transport properties of the cotton knitted fabrics in single jersey structure. Tekstil Ve Konfeksiyon 3: 218-223.

- Sdl Atlas (2010) Presentation Moisture management tester – An innovation in testing equipment.

- Supuren G, Oglakcioglu N, Ozdil N, Marmarali A (2011) Moisture management and thermal absorptivity properties of double-face knitted fabrics. Text Res J81: 1320-1330.

- Umbach Kh (1993) Aspects of clothing physiology in the development of sportswear.

- Umbach KH (2001) Optimization of the wear comfort by suitable fibre, yarn and textile construction.

- Vasconcelos FB (2006) Parameters for the development of sporting goods.

- Vasconcelos FG, Vasconcelos FB, Watanabe T (2014) Moisture management in sports shirts after washing.

- Yao B, Kwok Y, Li Y (2008) Precision of new method for characterizing dynamic liquid moisture transfer in textiles fabrics. Aatcc Review 8: 44-48.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi