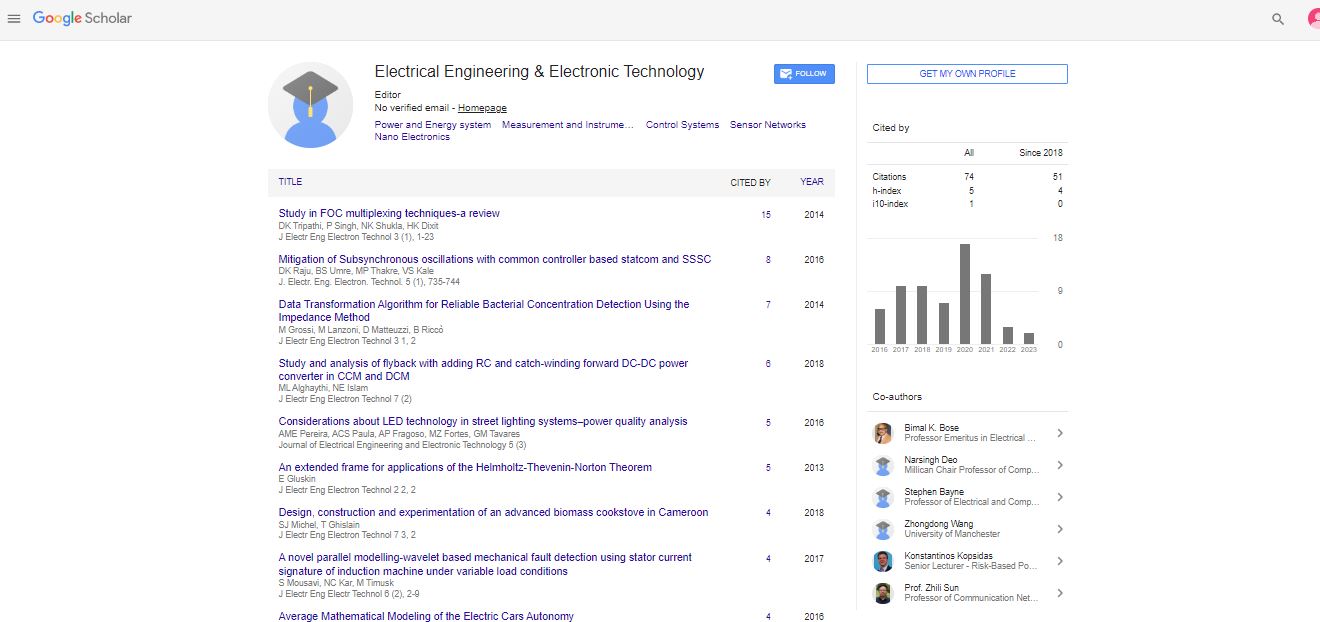

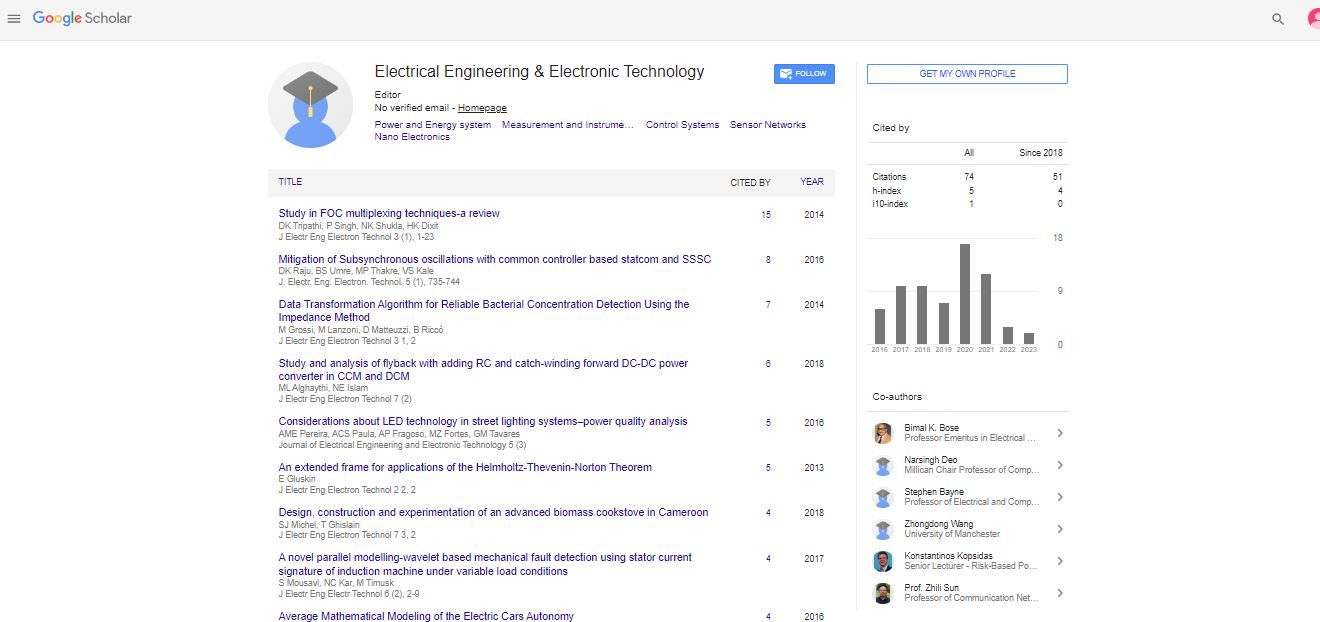

Research Article, J Electr Eng Electron Technol Vol: 10 Issue: 11

Heavy-Duty Cable Tray System

Mohammad Mulla1, Mohammed AlHamaidi2*

1Department of Management information system, Majmaah University, Saudi Arabia

2Department of Management information system, Majmaah University, Saudi Arabia

*Corresponding Author: Mohammed AlHamaidi

Department of Management information system, Majmaah university, Saudi Arabia

Tel: 0034648747211

E-mail: mohammed.alhamaidi@aramco.com

Received: August 11, 2021; Accepted: November 19, 2021; Published:November 29, 2021.

Citation:

Mulla M, AlHamaidi M (2021) Heavy-Duty Cable Tray System. J Electr Eng Electron Technol 10:11

Abstract

This paper presents an opportunity and design concept that will lead to a significant enhancement to the cable tray design, procurement, and construction by utilizing the heavy-duty cable tray system. This paper covers the length of six (6) meters horizontal cable trays with heavy- duty joint connectors and heavy-duty expansion joint connectors. In addition, the system includes heavy-duty horizontal bend fittings, heavy- duty horizontal tee fittings, and heavy-duty horizontal cross fittings. Typically, cable tray design in all projects follows the typical examples mentioned in the National Electric Manufacturing Association (NEMA) standards. In Saudi Aramco’s Tanajib Gas Plant project, a full report for the cable tray and structural steel design, containing detailed design calculations, shop tests witnessed by 3rd party inspection agency, and simulations were conducted to prove the compliance of the heavy-duty cable tray system with all applicable standard requirements.

Keywords: Cable tray design; Tanajib Gas Plant project; Horizontal cross fittings

Introduction

One of the difficulties that face many oil and gas projects is the demand of power that leads to significant amount of cables. Recently in Saudi Aramco projects, the preferred installation method for cables is utilizing aboveground cable trays to enhance the safety, reliability, and maintenance requirements. Thus, aluminum cable trays are the ideal option in recent projects that requires the pipe rack and cable tray supports to be properly designed.

Introducing the application of heavy-duty cable tray system will optimize significantly the quantity of supports required for the cable tray without affecting the quality, reliability, and safety of the facility. This will also eliminate the difficulties of the design and installation especially in congested areas where multiple curves and levels coincide. Moreover, this will improve the project schedule related to material delivery and installation.

This paper will demonstrate the comparison between NEMA VE-2 typical design and the improved design according to the manufacturer recommendation which utilizes the application of heavy-duty cable tray system based on horizontal 6m cable trays with heavy-duty joint connectors illustrated in Figure 1 and heavy-duty expansion joint connector illustrated in Figure 2. In addition, the system includes heavy-duty horizontal bend fittings, heavy-duty horizontal tee fittings, and heavy-duty horizontal cross fittings.

NEMA-VE2 Typical Design

In this section, we will explain the requirements of NEMA-VE2 typical design for the following

•Expansion joint connector shall have two supports located within 600 mm (2 ft.) on each side as illustrated in Figure 3

•Horizontal bend fitting shall have one support located in the center of the fitting and two supports within 600 mm (2 ft.) of each fitting edge illustrated in Figure 4

• Horizontal cross fitting shall have four supports under each side rail and four supports within 600 mm (2 ft.) of each fitting edge as illustrated in Figure 5

• Horizontal tee fitting shall have three supports under each side rail and three supports within 600 mm (2 ft.) of each fitting edge as illustrated in Figure 6

Improved Manufacturer Design

In this section, we will explain the requirements of the improved design according to the manufacturer for the following

• Expansion joint connector shall have one support located within quarter point of the expansion joint connector as illustrated in Figure 7

• Horizontal bend fitting shall have two supports within 600 mm (2 ft.) of each fitting edge as illustrated in Figure 8

• Horizontal cross fitting shall have four supports within 600 mm (2 ft.) of each fitting edge as illustrated in Figure 9

• Horizontal tee fitting shall have three supports within 600 mm (2 ft.) of each fitting edge as illustrated in Figure 10

Tests and Reports

The cable tray manufacturer in Tanajib Gas Plant project for Saudi Aramco submitted a full report ensuring and validating the compliance of the improved manufacturer design with NEMA, IEC, and Saudi Aramco standards.

As per Saudi Aramco SAES-P-104 standard dated 1 January 2018, the below criteria was followed

“9.4 The working load for cable trays shall consist of the weight of the cables (or tubing, etc.) including future additions (if required), plus a concentrated static load of 90 kg at the center of the span. The Working load shall not exceed the rated load capacity of the cable tray defined in NEMA VE 1 or NEMA FG 1 (destruction load divided by a safety factor of 1.5)”

“9.10 Deflection of the cable tray system (several sections spliced together as a continuous beam), when loaded to the working load as defined in paragraph 9.4, excluding the concentrated static load, shall not exceed L/100 (L=span length).”

Actual Load Tests

To verify that the heavy-duty cable tray system meets the mandated required loading capacity as per Saudi Aramco standards section 9.4, all fittings and multi-span straight cable tray sections were tested locally in the manufacturer shop and witnessed by an approved 3rd party agency per IEC 61537 Clauses 10.2, 10.3 & 10.7 and NEMA VE 1 Clause 5.2 where details are shown below

Horizontal Bend Fitting

The horizontal bend fitting was assembled as per Figure 11 using the recommended splicing device and mounted at the supports

The test procedure followed IEC 61537 Clause 10.2

Nominal Data

The horizontal bend fitting nominal data used for the actual load tests can be seen on Table 1 below

| Safe Working Load (SWL) | Total Leagth of Mid- Line of Fitting (La) | Width of Cable Tray Fitting (w) | Load Q | Load Qu |

|---|---|---|---|---|

| 149 kgim | 3,571.8 mm (3.5718 m) | 900 mm (0.9 m) | 532.20 kg | 904.74 kg |

Table1: Horizontal bend fitting nominal data

Where:

Table 1: Horizontal bend fitting nominal data

Load Q = Uniformly Distributed Load applied on the fitting = SWL x Lm

Load Q1.7 = Uniformly Distributed Load applied on the fitting with a safety factor of 1.7 = SWL x Lm x 1.7

Test Results

It was observed that the practical mid-span deflection @Load Q met the required acceptance criteria of (< ???? /100). Moreover, the sample sustained @Load Q1.7 without collapse. Thus, the testing result for Mid-Span deflection has passed. Detailed values can be seen on Table 2.

| Mid-Span Deflection | |||||

|---|---|---|---|---|---|

| @ Load Q | Point R | Point T | Average (R+T)/2 | Required | Remarks |

| 13.63 mm | 41.99 mm | 27.81 mm | < 35.7mm NO DAMAGE | PASSED | |

| @ Load Q1.7 | 15.78 mm | 52.62 mm | 34.20 mm | NO COLLAPSE | PASSED |

Table2: Horizontal bends fitting Mid-Span Deflection results

It was observed that the transverse deflection, which is the vertical deflection across the width of the base area, omitting the longitudinal deflection, when mounted horizontally, met the required acceptance criteria of (< (w)/20). Thus, the testing result for transverse deflection has passed. Detailed values can be seen on Table 3.

| Point S | Transverse (S Average) | Required (w)/20 | Remarks | |

|---|---|---|---|---|

| Load Q | 28.48 mm | 0.67 mm | 45mm NO DAMAGE | PASSED |

| Load QL7 | 35.52 mm | 1.32 mm | NO COLLAPSE | PASSED |

Table3: Horizontal bends fitting Transverse Deflection results

Horizontal Tee Fitting

The horizontal tee fitting was assembled as per Figure 12 using the recommended splicing device and mounted at the supports.

The test procedure followed IEC 61537 Clause 10.2

Nominal Data

The horizontal tee fitting nominal data used for the actual load tests can be seen on table 4 below

| Safe Working Load (SWL) | Total Leagth of Mid- Lime of Fitting | Distance Point to Point T (distRT) | Lead Q | Load Qu |

|---|---|---|---|---|

| 149 kg/m | 6,236.1 mm (6.2361 m) | 1,405.4 mm (1.4054) m) | 929.18kg | 1,579.6kg |

Table4: Horizontal tee fitting nominal data

Where:

Load Q = Uniformly Distributed Load applied on the fitting = SWL x Lm

Load Q1.7 = Uniformly Distributed Load applied on the fitting with a safety factor of 1.7 = SWL x Lm x 1.7

Test Results

It was observed that the practical mid-span deflection @Load Q met the required acceptance criteria of (< ???? /100). Moreover, the sample sustained @Load Q1.7 without collapse. Thus, the testing result for Mid-Span deflection has passed. Detailed values can be seen on Table 5.

| Point R | Point T | Average (R+T)2 | Required (L_/100) | Remarks | |

|---|---|---|---|---|---|

| @Load Q | 14.11 mm | 9.70 mm | 11.91mm | <62.3mm NO DAMAGE | PASSED |

| (Load Qu | 20.70mm | 14.82mm | 17.76mm | NO COLLAPSE | PASSED |

Table5: Horizontal tee fitting Mid-Span Deflection results

It was observed that the transverse deflection, which is the vertical deflection across the width of the base area, omitting the longitudinal deflection, when mounted horizontally, met the required acceptance criteria of (< ????????????/20). Thus, the testing result for transverse deflection has passed. Detailed values can be seen on Table 6.

| Point S | Transverse | Required (distRT)/20 | Remarks | |

|---|---|---|---|---|

| @L-Oad Q | 33.69 mm | 22.05 mm | 70.27 mm | PASSED |

| @Load Q1.1 | 5131 mm | 33.55 mm NO COLLAPSE | No collapse | PASSED |

Table6: Horizontal tee fitting Transverse Deflection results

Horizontal Cross Fitting

The horizontal cross fitting was assembled as per Figure 13 using the recommended splicing device and mounted at the supports.

The test procedure followed IEC 61537 Clause 10.2

Nominal Data

The horizontal cross fitting nominal data used for the actual load tests can be seen on table 7 below

| Safe Working Load (SWL) | Total Length of Mid- Line of Fitting (La) | Distance Point Rte Point T (distRT) | Load Q | Load Qu |

|---|---|---|---|---|

| 149 kgim | 8,314.8 mm (8.3148 m) | 2,068 mm (2.068 m) | 1,238.9 kg | 2,106.15 kg |

Table7: Horizontal cross fitting nominal data

Where:

Load Q = Uniformly Distributed Load applied on the fitting = SWL x Lm

Load Q1.7 = Uniformly Distributed Load applied on the fitting with a safety factor of 1.7 = SWL x Lm x 1.7

Test Results

It was observed that the practical mid-span deflection @Load Q met the required acceptance criteria of (< ???? /100). Moreover, the sample sustained @Load Q1.7 without collapse. Thus, the testing result for Mid-Span deflection has passed. Detailed values can be seen on Table 8.

| Mid-Spam Defection | |||||

|---|---|---|---|---|---|

| Poim R | Poim T | Average (R+T)l2 | Required (lm/100) | Remarks | |

| @Lo:1d Q | 9.74 mm | 8.59mm | 9.17 DIDI | $ 83.1nm1 NO DAMAGE |

PASSED |

| @Load Q,,, | 17. Q? mrn | 16.26 mm | 16.67 nm1 | NO COLLAPSE | PASSED |

Table8: Horizontal cross fitting Mid-Span Deflection results

It was observed that the transverse deflection, which is the vertical deflection across the width of the base area, omitting the longitudinal deflection, when mounted horizontally, met the required acceptance criteria of (< ????????????/20). Thus, the testing result for transverse deflection has passed. Detailed values can be seen on Table 9.

| Point S | Transverse | Required (distR1)1'20 | Remurks | |

|---|---|---|---|---|

| @V>nd Q | 58.00 mm | 48.83 mm | 103.4 mm NO DAMAGE |

PASSED |

| .@Load Q1.7 | 93.87 llUll | 77.20 mm | NO COLLAPSE | PASSED |

Table9: Horizontal cross fitting Transverse Deflection results

Multi-Span Straight Cable Trays

The multi-span straight cable trays (5 spans) was assembled as per figure 14 using the recommended splicing device and mounted at the supports.

The test procedure followed IEC 61537 Clause 10.3 and NEMA VE1 Clause 5.2.

Nominal Data

| Rated Load | Maximum Mid-Span Deflection(Lm/100) | Total Test Load |

|---|---|---|

| 149kg/m@6mSpan | 60mm | 4470kg |

Table10: Multi-span straight cable trays nominal data

Where:

Total Test Load = 5 SPANS x 149 kg/m PER SPAN

= 5 * 149 kg/m * 6 m = 4470 kg

Test Results

It was observed that the average deflection span @100% total test load met the required acceptance criteria of (< ???? /100). Thus, the testing result for average deflection span has passed. Detailed values can be seen on Table 11.

| Total Test Load | Average Deflection Spas (Ead) | Average Deflection Span | Average Deflection Span 3 (Center) | Average Deflection Span 4 | Average Deflection |

|---|---|---|---|---|---|

| 100% | 45.88mm | 14.01mm | 26.30mm | 11.42 mm | 53.94 mm |

Table11: Multi-span straight cable trays average deflection span results

Simulation Validation

The design was validated by simulating several recommended tests and utilizing ANSYS software that can validate the actual test performed in order to be installed in an industrial environment. The results of the validation exercise have been reviewed by Saudi Aramco’s engineering consultation committee including civil, structural and electrical consultants.

Static Structural Analysis

A simulation of static structural analysis using the nominal data on table 12 was performed to validate the average deflection span results.

| Rated Load | Maximum Mid-Span Deflection(Lm/100) | Total Test Load |

|---|---|---|

| 149kg/m@6mSpan | 60mm | 4470Kg |

Table12: Multi-span straight cable trays nominal data (simulation)

Nominal Data

Where:

Total Test Load = 5 SPANS x 149 kg/m PER SPAN

= 5 * 149 kg/m * 6 m = 4470 kg

Test Results

It was observed that the average deflection span @100% total test load met the required acceptance criteria of (< ???? /100). Thus, the testing result for average deflection span has passed. Detailed values can be seen on Table 13.

| Total Test Load | Average Deflection Spas (Ead) | Average Deflection Span | Average Deflection Span 3 (Center) | Average Deflection Span 4 | Average Deflection |

|---|---|---|---|---|---|

| 100% | 21.4mm | 15.3mm | 16.9mm | 15.3mm | 21.4 mm |

Table13: Multi-span straight cable trays average deflection span results (simulation)

Thermal Structural Analysis at Maximum Temperature

A simulation of thermal structural analysis at maximum temperature using the nominal data on table 14 was performed to validate the average deflection span results.

| Rated Load | Maximum Mid-Span Deflection(Lm/100) | Total Test Load | Max tenperature |

|---|---|---|---|

| 149kg/m@6mSpan | 60mm | 4470kg | 55degc |

Table14: Multi-span straight cable trays nominal data (simulation)

Nominal Data

Where:

Total Test Load = 5 SPANS x 149 kg/m PER SPAN

= 5 * 149 kg/m * 6 m = 4470 kg

Test Results

It was observed that the average deflection span @100% total test load met the required acceptance criteria of (< ???? /100). Thus, the testing result for average deflection span has passed. Detailed values can be seen on Table 15.

| Total Test Load | Average Deflection Spas (Ead) | Average Deflection Span | Average Deflection Span 3 (Center) | Average Deflection Span 4 | Average Deflection |

|---|---|---|---|---|---|

| 100% | 25.7mm | 13.6mm | 16.9mm | 13.5 mm | 26.1 mm |

Table15: Multi-span straight cable trays average deflection span with max temperature results (simulation)

Thermal Structural Analysis at Minimum Temperature

A simulation of thermal structural analysis at minimum temperature using the nominal data on table 16 was performed to validate the average deflection span results.

Nominal Data

| Rated Load | Maximum Mid-Span Deflection L_/100) | Total Test Load | Min. Temperature |

|---|---|---|---|

| 149 kg/m @ 6m Span | 60 mm | 4470kg | O deg C |

Table16: Multi-span straight cable trays nominal data (simulation)

Where:

Total Test Load = 5 SPANS x 149 kg/m PER SPAN

= 5 * 149 kg/m * 6 m = 4470 kg

Results

It was observed that the average deflection span @100% total test load met the required acceptance criteria of (< ???? /100). Thus, the testing result for average deflection span has passed. Detailed values can be seen on Table 17.

| Total Test Load | Average Deflection Spas (Ead) | Average Deflection Span | Average Deflection Span 3 (Center) | Average Deflection Span 4 | Average Deflection |

|---|---|---|---|---|---|

| 100% | 25.9mm | 13.8 mm | 17.2mm | 13.7mm | 26.3 mm |

Table17: Multi-span straight cable trays average deflection span with min temperature results (simulation)

Recommendations and Limitations

As a result of the manufacturer report, recommendation and limitations were developed in order to ensure the design capability and the installation integrity as per the below

• Installation shall be limited to horizontal cable tray runs. Vertical cable tray runs shall be installed as per the requirements of NEMA VE-2

• Fittings shall not be installed immediately before or after a heavyduty expansion plate

• Only 3 types of fittings are considered which are horizontal bend fittings, horizontal cross fittings, and horizontal tee fittings

• Cable tray fitting supports shall be located within 600 mm of cable tray fitting end

• Cable tray supports shall be located within quarter span of all straight cable tray adjacent to the cable tray fitting

Conclusion

In this paper, we have demonstrated an improved design for the cable tray system by utilizing the heavy-duty cable tray system that will improve the design and installation of the structural steel and cable tray system. Concerning the design, the heavy-duty system eliminates the complexity of the design especially in congested areas where multiple curves and levels coincide that mainly affects maintenance requirements. In addition, concerning the installation, the heavy-duty cable tray system reduces the quantity of material needed for the structural steel thus improving the schedule of the installation. For this case study, applying the heavy- duty cable tray system in Tanajib Gas Plant eliminated more than 15,000 supports of around 270 km of cable trays.

References

- Saudi Aramco Engineering Standard SAES-P- 104 2018, Wiring Methods and Materials

- IEC 61537 2006, Cable Management – Cable Tray Systems and Cable Ladder Systems

- Wahah Electric Supply Co. of Saudi Arabia Ltd. Cable Management System Report

- NEMA VE1 2017, Metal Cable Tray Systems

- NEMA VE2 2018, Cable Tray Installation Guidelines

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi