Research Article, J Fashion Technol Textile Vol: 11 Issue: 5

Fabrication of Chemically Modified Jute Fabric and Nonwoven Wet-Laid Glass Fiber Reinforced Polycaprolactone Composite

Ajoy Roy* and Fahad Halim

Department of Fashion Technology and Textile Engineering, BGMEA University of Fashion and Technology (BUFT), Dhaka, Bangladesh

- *Corresponding Author:

- Ajoy Roy

Department of Fashion Technology and Textile Engineering,

BGMEA University of Fashion and Technology (BUFT),

Dhaka,

Bangladesh;

E-mail: luobuma6@gmail.com

Received date: 26 February, 2020, Manuscript No. JFTTE-23-7769;

Editor assigned date: 02 March, 2020, PreQC No. JFTTE-23-7769 (PQ);

Reviewed date: 16 March, 2020, QC No. JFTTE-23-7769;

Revised date: 19 July, 2023, Manuscript No. JFTTE-23-7769 (R);

Published date: 16 August, 2023, DOI: 10.4172/2329-9568.1000310

Citation: Roy A, Halim F (2023) Fabrication of Chemically Modified Jute Fabric and Nonwoven Wet-Laid Glass Fiber Reinforced Polycaprolactone Composite. J Fashion Technol Textile 12:4.

Abstract

In recent decades, scientific research giving more attention to the development of bio-based polymer composites due to the extensive usage of petroleum-based fillers as well as polymer matrices for the generation of polymer composites. In this study, high-moisture regain nature of cellulosic jute fiber significant drawback for jute-based application to reduce the issue and develop better interfacial adhesion hydrophobic nonwoven PP wet-laid glass-fiber matt used with polycaprolactone as a matrix. Nonwoven jute fabric categorized in untreated, silane, alkali and silane alkali combined modified afterward compounded with the solution of Polycaprolactone (PCL). Fabrication of composite performed following sandwich method according to different hot-pressing time, pressure and temperature for detecting a prominent fabrication parameter. Hence, mechanical properties like tensile and impact strength investigation performed to find the consequence after chemical treatment from the non-woven jute fabric resulting in 48.38%, 32.04% improved in tensile strength and modulus with 39.58% reduced impact strength in alkali silane combined treated composite over untreated optimized composites the Scanning Electron Microscope (SEM) used for displaying interfacial adhesion between fiber and polymer matrix. Besides, further investigation demonstrating due to combined treatment of alkali and silane optimized composites significantly enhanced the Thermogravimetric (TGA) stability in contrast to other composites.

Keywords: Bio-composites, Poly-caprolactone, Woven jute fabric, Chemical treatment, Mechanical properties, Nonwoven wet-laid glass fiber

Introduction

Composite is a substance that's formed using mixing two or more verity of substances in such a way that the outcome substances delivered with properties superior contrast to ordinary ones. Polymer matrix-based reinforces composite got comparatively more attraction compared to ceramic and metal matrix as well as in the area of textile and material research. The exceptional resistance of glass fibers into the ecological assault produced glass-fiber-reinforced polymers more appealing among food and chemical sectors as well as due to low elongation at break, better stiffness and strength with preferable properties turned PCL significant biopolymer contributor in the area of tissue engineering, medical surgery, aerospace, construction industry, automobile, environmental engineering application as well as unremittingly opening new industrial possibilities are broadening day by day [1].

Ordinary jute can be utilized for elementary and non-invasive industrial textile items, whether expected property achieved throughout proper modification, as well as the industry can be capable of offering professional and environmentally friendly products within a reasonable price. Jute has a good enough mechanical property of high specific mechanical strength, good moisture regain (13.75%) and 100% degradable, renewable resources, ease of access, lower-cost, highly breathable and lower contamination emission to nature [2]. These factors make jute fiber along with coir, flax, sisal, pineapple, ramie, hemp and kenaf a high point of interest for researchers for using as a reinforcing material. As a second, most used organic fiber jute will be an outstanding substitute, whereas prospective high specific strength, nonrenewable resources and a comparatively lower price is an important issue. On the other hand, glass fiber gained enormous attention from the past century to the researchers in compared to other synthetic fiber benefits including significant stiffness, high heat, corrosive and impact resistance, comparatively lower price and simplicity of setup, better processability, relatively better immunity to environmental substances and fatigue. For this reason, a substitute for concrete, wood and metal materials with glass fiber used a broad array utilizing in fabricating different types of composites such as insulation, heat and corrosion-resistant application and noise reduction [3].

K Jarukumjorn et al. investigated the tensile strength and bending strength improved after using glass fiber as reinforcement in the sisal- PP composite without influencing tensile and bending modulus as well as significant improvement exhibited in the thermal degradation along with moisture absorption properties of the composite. Manually chopped short length jute with glass fiber reinforced hybrid PET composites exhibit significant improvements in mechanical property due to affecting heap order. R Velmurugan et al. studied adding glass fiber with palmyra hybrid composite improves the mechanical property and adding extra glass fiber exhibited further improvements in successive rate. Huq Tanzina, et al. performed a comparative interfacial property evaluation of jute glass-fiber-reinforced PET composite results exhibited glass matt-pet composites comparatively better mechanical (Tensile, flexural and water absorption) properties compared to other composites in the experimental group. M Boopalan, et al. executed a comparative investigation in jute-sisal reinforced PLA biocomposites where jute reinforced PLA biocomposites outcome revealed significantly improved mechanical properties than sisal. T Munikenche Gowda et al. analyzed the mechanical property test of jute-glass-fiber reinforced polyester figured even though mechanical properties of jute/polyester composites tend not to own matrix and strengths as large as those of other traditional composites, they could process much better advantages than timber composites and several plastics.

Besides, they have some drawbacks, too; weak interfacial adhesion between natural fiber and thermoplastic is the major problem that can overcome by treating the surface of fiber using different chemical processing [4]. Alkali treatment washes out the impurities of fiber and increases the interfacial bonding between the fiber and thermoplastic polymer as well as micro-fibril rearrange of cellulosic content and lignin dissolving of highly hydrophobic content of fiber. After investigating previous studies, soaking jute fibers fiber in a solution of silane coupling agent for surface treatment resulting in better mechanical properties with strong interfacial adhesion also exhibited slightly improved outcomes in thermal stability over untreated even more then alkali-treated bio composites broadly contemplated in.

Gassan et al. performed an investigation in epoxy with 3- glycidoxypropyl trimethoxysilane (KH560) treated jute and concluded with a result of enhanced 100% of dynamic modulus over untreated experimental composites. Wang Xue, et al. studied woven jute with silane coupling agent (KH560) modified epoxy laminated composite trend to better adhesion between fiber epoxy with enhanced crystallinity and thermal stability, 10 times better silicon grafted in jute fiber exhibit upon EDS observation as well as tensile strength (42%), tensile modulus (39%), bending strength (49%) and flexural modulus (51%) enhanced due to silane treatment compared to untreated woven jute which is comparatively better than few wood-based composite application. Having OH and amine (primary NH2 secondary NH4) groups, the silane coupling agent can help to set up a bond between the fibers and Polycaprolactone (PCL) [5].

Debeli et al. performed comparative investigation and result exhibited natural fiber reinforced PLA biocomposites and concluded with fiber, which surfaces treated with silane coupling agent and alkali exhibited noticeable outstanding results in the area of tensile strength and modulus, flexural strength and impact strength as well as enhanced burial degradation process demonstrated over untreated bio composites. Both jute and glass fiber have a significant property to develop advanced products as well as further research needed [6].

However, only a few researchers investigated and fabricated woven jute and wet laid glass fiber sheet reinforced PCL composites using hot pressing. In this research paper, jute fibers chemically treated (Silane coupling agent, alkali and combined) along with commercial untreated woven jute fabric for the comparative purpose and design containing eight optimized sample prepared throughout the hotpressing method according to different compression molding temperature, time and pressure to find out preeminent processing condition for the optimized nonwoven jute and glass fiber reinforced PCL composites.

Materials and Methods

In this experiment, Polycaprolactone (PCL) granules used as a matrix, Dichloromethane (DCM) used as a solvent for dissolving PCL. Alkali (sodium hydroxide)-NaOH ≥ 98% pure, and silane coupling agent (3-glycidoxypropyltrimethoxysilane)-KH560 ≥ 98% with a molecular weight of 236.34 used for fiber surface modification supplied from mike chemical instrument co. Ltd, Hongkong. Moreover, woven jute fabric collected from the local market of Narsingdi, Dhaka, Bangladesh-1200, then cut manually 20 × 20 cm and specimens comprising 40 wt% jute fibers fabricated using the hotpressing method. Nonwoven wet-laid glass fiber sheet obtained from Dalian filter material co. Ltd, China, for using as a reinforcement of PCL (Table 1) [7].

| Properties | Jute | Glass fiber | PCL |

|---|---|---|---|

| Density (g/cm3) | 1.3 | 2.5 ± 0.1 | 1.13 |

| Molecular weight | 38000 | ||

| Melting temp (oC) | 650 ± 15 | 59-64 | |

| Thickness (mm) | ≤ 1.2 | ||

| Glass transition temp (oC) | 155 | -64 |

Table 1: Detail mechanical properties of jute, glass fiber sheet and polycaprolactone.

Fiber treatment and composite fabrication

A solution of 7% (7 g for 100 mL water) NaOH has been prepared. Jute fiber matt (20 × 20 cm) dipped in a solution of 7% NaOH and dried in a woven (Shanghai Hasuc tools fabricate Co. Ltd. Model: DHG-90538) at 80°C temperature for 60 minutes. After completion of drying, kept 9 hours at room temperature. Again, jute fibers saturated in a solution of KH-560 (7 g/100 ml water) and kept for a maximum of 10 hours at room temperature. Moreover, non-woven jute fibers were saturated in a solution of 7% NaOH and 7% KH-560/100 ml water for comparison purposes [8]. Furthermore, due to comprises an epoxy group in KH-560 that functions as an organofunctional silane lead to enhance comparatively better interfacial adhesion among fibers and reinforced matrix.

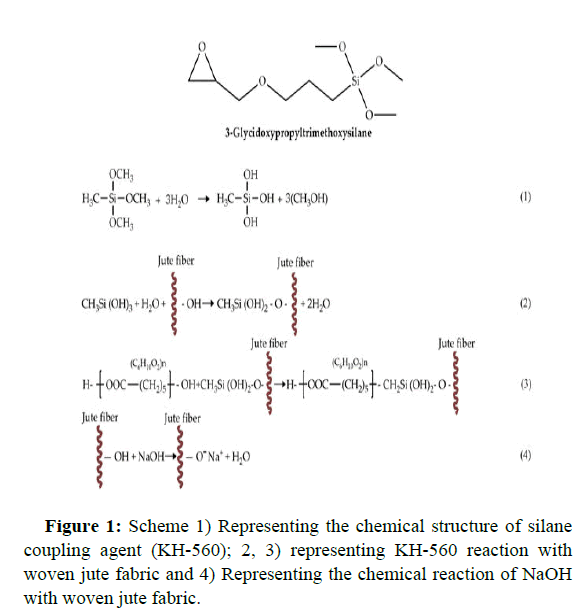

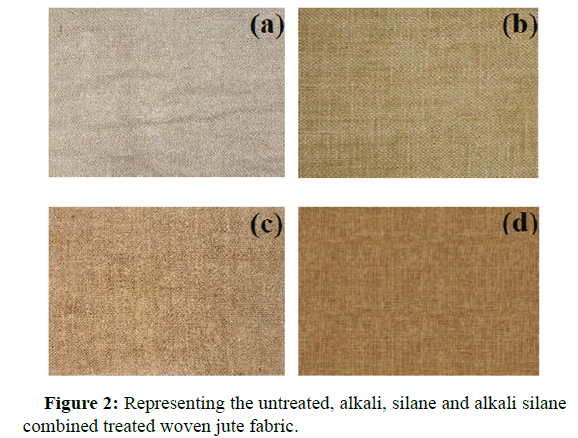

A three-stage mechanism of KH-560 with jute fiber as well as NaOH chemical reaction with jute fibers representing in Figure 1. In the primary stage, silanol and alcohol formed using a reaction with water and a stable covalent bond also created using reaction with a fiber hydroxyl group. Methyl functional group of silane will react with the matrix hydroxyl group when they reinforced together; thus, an enhanced bond formed within matrix and silane coupling acid trend to enhanced interfacial adhesion within jute fiber and PCL matrix. Afterward, both treated jute fibers had rinsed with regular water using acetic acid till surplus alkali (NaOH) and silane (KH-560) removed away and maintained a pH value of 5 for both chemically treated fiber due to enhancing hydrolysis process. Subsequently, completion of the treatment process, both treated fibers dried in woven at 8°C for 5 hours separately for reduced the absorbed moisture content and eliminate unwanted void space during the fabrication of composites (Figures 1 and 2) [9].

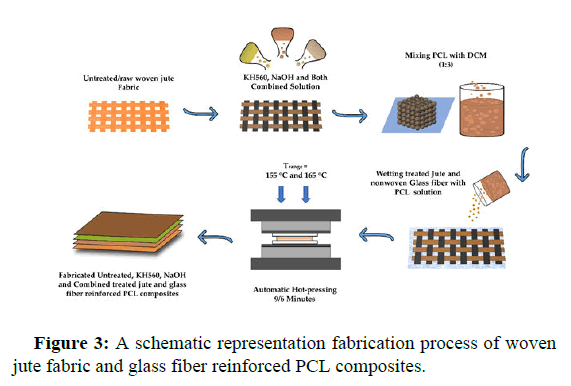

The treated woven jute fibers exposed to open air for five days, then a solution of PCL (1:3 ratio PCL:DCM) took in a glass beaker and mixed using electric stirrer almost 90 minutes until PCL granules dissolve properly within DCM solvent. Woven jute fabric were wetted with PCL solution manually and dried 2 h at room temperature before going through the fabrication process of composites, a design containing eight samples followed closely, as well as a hot-pressing process, was selected and intended to detect a compatible condition for assembling composite based on different hot-pressing temperatures of 155°C and 165°C, time 9-minute heating with 6-minute cooling and pressure of 7 MPa respectively. Figures 2 and 3 depicts different samples and methods of preparing samples (Table 2) [10].

| Sl. No | Chemical treatment | Sample denotations | Temperature (oC) | Heating time (min) | Pressure (MPa) |

|---|---|---|---|---|---|

| 1 | Untreated | R-1 | 155 | 9/6 | 7 |

| 2 | Untreated | R-2 | 165 | 9/6 | 7 |

| 3 | KH560 | S-1 | 155 | 9/6 | 7 |

| 4 | KH560 | S-2 | 165 | 9/6 | 7 |

| 5 | NaOH | A-1 | 155 | 9/6 | 7 |

| 6 | NaOH | A-2 | 165 | 9/6 | 7 |

| 7 | KH-560+NaOH | C-1 | 155 | 9/6 | 7 |

| 8 | KH-560+NaOH | C-2 | 165 | 9/6 | 7 |

Table 2: Detailed process and parameter for fabricating woven jute and glass fiber reinforced composites.

Characterization

Fourier Transform Infrared (FTIR): Fourier Transform infrared (FTIR) performed to observe the spectra change and surface functional groups due to chemical treatments. Dried 2 mg powder of jute fiber mixed with KBr further compounded into a fine powder using mortar and pestle and then compressed. Jute fiber both treated and untreated surface chemistry analyzed using (Nicolet, Model: iS50 FT-IR) within a range of 500 cm-1-4000 cm-1 [11].

Tensile strength and modulus: Tensile strength and modulus test completed and documented data at room temperature of 20°C and 65% relative humidity employing a computer-controlled Instron tester (Model: 5943, Instron shanghai ltd.) The entire testing achieved following the standard of GBT-1447-2005 with a loading speed rate of 5 mm/min. For tensile strength, modulus and impact strength, every specimen tested a minimum of 5 times and averaged data selected for investigation [12].

Impact strength: Impact strength of woven jute and glass fiber reinforced PCL composite performed at room temperature of 20°C and 65% relative humidity according to Chinese standard GB/T 1451-2005. Using a version of XB-OTS-C500 impact tester (Dongguan Xin bao Instrument Co., Ltd. China). The specimen, size was 64 × 13 × 3 mm [13].

Water absorption: WA and measured following ASTM D570 and each of the calculations and outcomes performs the following standard. Before immersion, all prepared samples dried at 60°C for 5 hours afterward WA test has been sustained till 180 hours. Each of the outcomes listed carefully within the specified time using Yueping automatic electrical balance (capacity of min: 10 milligrams max: 100 gm, model: FA1004B, Shanghai Yueping scientific tool Co., Ltd. China) in room temperature [14].

Mt (%)=(Mt-M1)/M1 × 100

Where, Mt stands for sample weight, t for immersion time and M1 is initial dry sample weight.

Thickness swelling: Thickness Swelling (TS) conducted according to ASTM, D570 standard. Prepared specimens immersed in distilled water and recorded data in room temperature at 20°C and 65% humidity using a thickness tester. In total, five times tested every optimized sample and averaged to get the accurate data.

Thermogravimetric analysis of optimized composites: Thermogravimetric or Thermal Decomposition Analysis (TGA) of woven jute and glass fiber reinforced PCL composites studied to observe the thermal degradation behavior of treated and untreated composites. Whereas the sample weight was 3 mg-8 mg, temperature range and the rate were respectively 30-600 (°C) and 20°C/min-1 using (NETZSCH model: TG209 F1 Libra; Germany) [15].

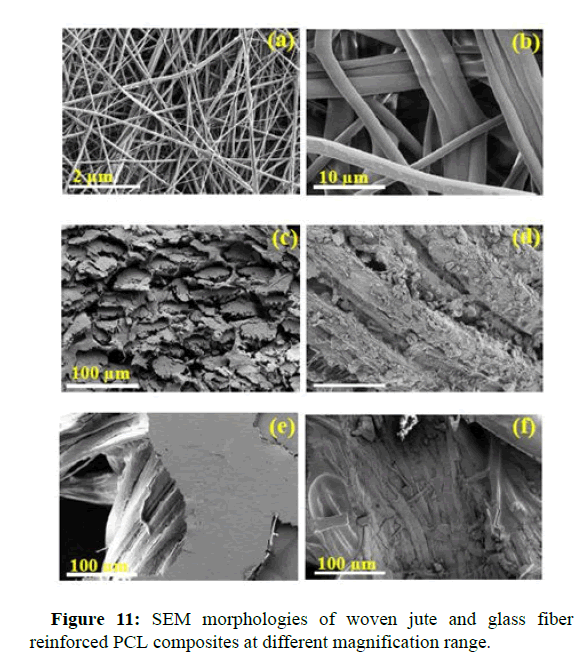

Morphology analysis of optimized composites: The morphological composition of nonwoven jute and glass fiber reinforced PCL composites were studied to see the interfacial adhesion between fiber and matrix using an SEM (Scanning Electron Microscopes JSM-5610LV from JEOL, Japan) after being coated with gold (JFC-1600 fine auto coater from JEOL, Japan). The SEM specimen received from fracture during the tensile strength test.

Results and Discussion

Characterization of treated and untreated composites surface chemistry

The consequences of silane and alkali treatments significantly enhanced the mechanical properties of woven jute and glass fiber reinforced PCL composites over untreated composites distinctly observed in outcomes. The treated and untreated composites revealed a broad and powerful vibration spectrum in 3435 cm-1, 3440 cm-1, 3439 cm-1 and 3434 cm-1 for untreated, silane, alkali and combinedtreated jute suggesting O-H stretching vibration due to cellulose (Figure 4).

In 2950 cm-1 and 2871 cm-1 vibration peak detected for methyl and methylene group (cellulose and hemicellulose) revealed by C-H stretching that transfer to 2917 cm-1, 2865 cm-1 for silane in alkali 2942 cm-1, 2865 cm-1 and combined treated jute which is slightly minimized and transferred to 2915 cm-1 and 2853 cm-1 respectively. The robust peak is showing in untreated jute at 1730 cm-1 corresponding vibration stretching from the carboxylic acid (C=O) and ester attributing of having hemicellulose content in jute fiber which due to structural change shifted silane 1743 cm-1 and alkali 1733 cm-1 after chemical treatment. Besides, absorption spectra detected at 1465 cm-1 represents -CH3 bond, peaks presenting in 1375 cm-1 and 1248 cm-1, respectively attributing of lignin C-H stretching vibration. These peaks minimized in the treated spectra are an indication of lignin removed after chemical treatment.

Furthermore, peaks presenting in untreated jute fiber spectra around 1045 cm-1 attributed to cellulose. As stated in Figure 4, small spectra in combined treated jute, indicating near 1000 cm-1 due to asymmetric stretching vibration of Si-O-Si or cellulose-O-Si bonds because of possible reaction among cellulose hydroxyl and hydrolyze of silane. KH560 holds OH and NH2 group, which creates a connection involving treated fibers with the matrix as well as occupying polar and non-polar groups supplied maximum pressure and heat significantly toward treated fiber throughout composites fabrication.

Tensile strength and modulus

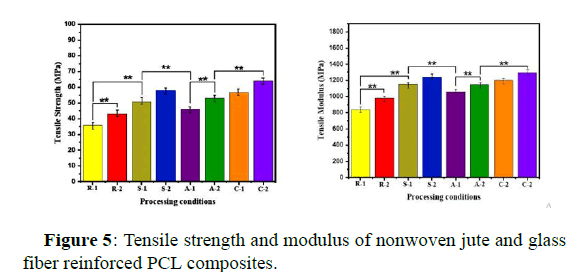

Figure 5 exhibiting the tensile strength and modulus (MPa) of nonwoven jute and glass fiber reinforced PCL composites for various preparing conditions (preparing conditions 1, 2, 3, 4 ....8), as displayed in Figure 5.

Proper working parameters are incredibly potential to provide outstanding results together with the essential chemical and physical attributes required. The chemical treatment effect observed from the outcomes of composite mechanical properties. As demonstrating, combined-treated composite sample C2 (7% of NaOH and KH560 with 165°C temperature and 7 MPa pressure) exhibiting a substantial maximum effect over other composites. The fiber mass volume ratio has a vital role in keep and dispersing by PCL construction via an external heat and load supplied on composites. Furthermore, 9 minutes of hot-pressing with 6 min cooling considered appropriate requirements for this experimental group to get extraordinary results. Mechanical properties of composite mostly depend on interfacial adhesion between fiber and matrix as well as individual fiber and matrix strength and modulus.

Alkali and silane combined treatment occur potential physical and chemical modification into fiber surface resulting in better interfacial bonding with enhanced tensile strength and modulus over untreated fiber. Because insufficient heat transfer fails to spread PCL properly through jute fabric leads to improper wettability to the surface of jute fiber as well as the interface of glass fiber, causing comparatively weak interfacial adhesion between untreated jute fiber and PCL consequences sample R1 displaying the lowest results in the experimental group. Combined treatment in nonwoven jute fiber matt significantly reduces jute fiber stiffness with increased fiber surface roughness develops better interfacial adhesion within jute fiber and PCL, resulting in exhibiting better tensile strength and modulus, which is almost 48.37% and 32.04% higher compared to untreated composites tensile strength and modulus. Similarly, tensile modulus demonstrating more or less similar results with the tensile strength of composites.

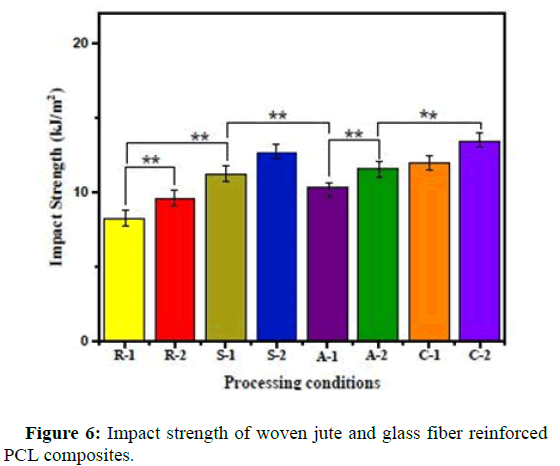

Impact strength

The outcomes of woven jute and glass fiber reinforced PCL composites in the impact test exhibited in Figure 6. The chemicallytreated woven jute composites showed considerable improvements in the impact strength in contrast to untreated jute and glass fiber reinforced PCL composite and further increment occurred with increasing fiber loading based on previous research. Chemically treated composites demonstrating the highest impact result compared to untreated composite due to high stiffness with PCL trend to enhanced interfacial adhesion between jute and matrix. Besides, a higher% of Volume Fraction (VF), strength and stiffness of glass fiber influenced in interfacial adhesion as well as mechanical properties of composites.

Alkali treatment washed out impurities by sparking the surface and also leaves that the roughness with several pits onto the fiber surface, which subsequently contributes to better stiffness, strong interfacial bonding between reinforced matrix with compromising reduced impact strength of composites. Optimized sample R1 indicating the lowest impact strength among optimized processing composites. This can be an indication of weak interfacial adhesion within untreated woven jute fibers with the PCL matrix. Similarly, as reported in Figure 6, the optimized sample A2, revealed moderate result over other composites, which 39.58% less compared to combined treated optimized sample C2. Furthermore, a suitable processing condition (hot pressing temperature, pressure and time) is an essential component in embellishing woven jute, glass fiber sheet and PCL into a competitive composite.

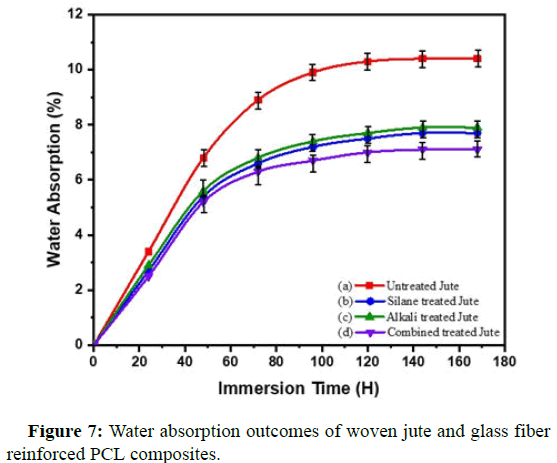

Water Absorption (WA)

WA test performed to observe the amount of moisture absorption of optimized composites (R2, A2, S2 and C2) after immersion in distilled water for a specific period and the result are displayed. Figure 7 exhibiting the effect variation due to consuming water in air-filled voids and pores contribute to up-taking more water and increase the weight of composites. Moisture absorption of composite influenced by cellulosic fiber content, matrix fiber stiffness, hardness, void or empty hole in composite, humidity and temperature. As demonstrated, untreated jute and glass fiber reinforced PCL composite optimized sample R-2 consumed more water in the air-filled void and pored basically created during fabrication of composites over treated composites, which is 31.73% more than silane treated optimized sample S-2.

That is an indication of changing in dimensional stability of the cellulose-based composites. The WA behavior of composites determined by the capability of their fiber to consume water or moisture due to the existence of hydroxyl groups that mainly responsible for WA throughout the creation of Hydrogen (H) bonding. The higher the moisture content of any organic fiber, the higher the alteration in the mechanical and physical characteristics of the composites, resulting in lower adhesion between reinforced matrix with fiber. For this reason, untreated jute and glass fiber reinforced PCL composites displayed maximum WA that is 10.4%. Besides, silane and alkali treatment enhanced jute fiber roughness topography and improved aspect ratio influenced in better fiber-matrix interfacial adhesion, including air-filled voids and pore filled up throughout the preparation of composite trend to lower water uptake.

Moreover, glass fiber matt is highly hydrophobic that limits the moisture consumption between glass and jute fiber due to the high toughness nature of the PCL matrix. After conducting WA, we observed the common tendency of composites showing significant changes in weight with extent immersion time as well as consuming excess moisture at the beginning of immersion until achieved a stable condition.

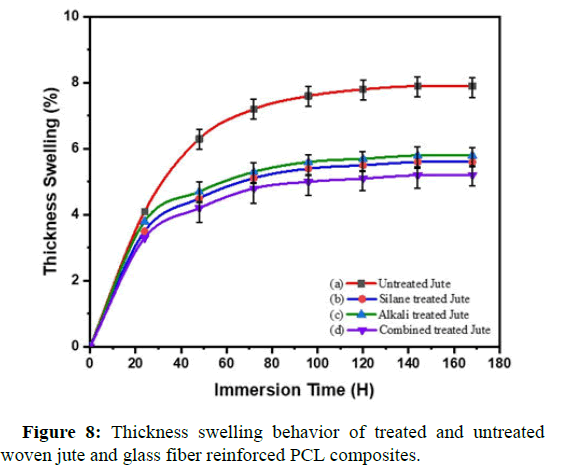

Thickness Swelling (TS)

Thickness swelling behavior of both treated and untreated optimized composites exhibited in Figure 8. TS of composite has been arising predominantly due to the vulnerability of lignocellulosic fiber around the surface of composite because the amount of lingo cellulosic fiber varies with distinct moisture material. The hydrophilic properties of lingo cellulosic substances with medium called capillary action get the consumption of water once the specimens saturated in water consuming the fiber resulting in changing the dimensional stability of the composite.

Figure 8 demonstrated that the untreated optimized composites R-2 showing maximum results due to this reason among the optimized experimental group, which is around 7.9%. Which is also an indication of low interfacial adhesion, micro air-filled void space and pores appear in the composite that uptake the water inside those micro-voids and pores take part in changing dimensional stability with reversible and irreversible swelling of the composites. Besides, the lowest TS result exhibiting the combined treated optimized sample C-2 after 180 hours of immersion, which is respectively 12.06% lower than alkali-treated optimized sample A-2 and 8.92% for silane treated optimized sample S-2 attributed to comparatively better reducing the hydroxyl (OH) group responsible for water uptake with chemical treatment. At the beginning of immersion, the untreated composites incessantly uptakes more water and showing exceeding TS change than the treated reinforced composites. In addition, silane treatment, Hydrogen (H) and a covalent bond formed with polymer matrix resulting in enhanced fiber-matrix adhesion. It summarized from Figure 7, combined treated woven jute and glass fiber reinforced composite exhibited the lowest result, whereas silane and alkalitreated jute and glass fiber reinforced composite showing moderate result over untreated composite, which recorded the highest score in the optimized experimental group.

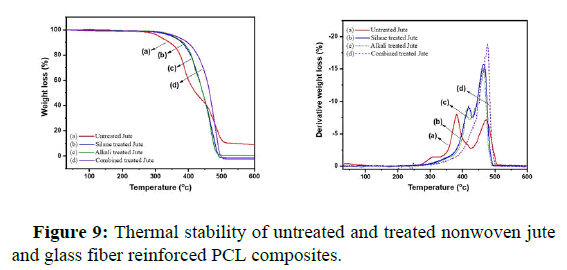

Thermogravimetric analysis of composites

The Thermogravimetric Analysis (TGA) outcomes affirmed that the chemical treatments of woven jute fabric in jute and glass fiber reinforced PCL composites raised the operation of degradation resistance for these optimized processing composites, as exhibited in Figure 9.

Thermal stability is an essential property of fiber-reinforced composites. Untreated composite decomposed in two-stage and started decomposing at lower temperatures compared to treated composite corresponding optimized samples, as demonstrated in Figure 9, both WL% and DWL% graph. Untreated jute initiated the first degradation step around 250°C, and the second stage starts from 449°C, which proceeded to accomplish decomposition around 520°C. Alkali-treated composite overcomes this tendency and degradation completed in a single step due to the removal of hemicellulose as well as increase and decreasing of PCL reinforced molecular mass comparatively affects the thermal degradation process of the composites. Besides, chemically treated woven jute and glass fiber reinforced PCL composites exhibiting improved thermal stability and enhanced the degradation of the composite over untreated composites.

The thermal decomposition starts for alkali-treated composite from 302.5°C following reached to the ultimate stage near about 500.8°C. As demonstrated, combined treated nonwoven jute and glass fiber reinforced PCL composite exhibited bit enhanced thermal stability compared to silane and alkali-treated composite, which is an indication elimination of natural hydrolyzed elements that decompose before that lignin and cellulose. Moreover, decomposition of jute fiber can describe by heat range between 25°C-150°C composites weight loss indicated because of water volatilization, the second peak allocating between 190°C-300°C, indicating the degradation of hemicellulose, the third peak showing between 300°C-360°C attributed to the degradation of cellulose. Moreover, lignin degradation takes place between 280°C-500°C (Table 3).

| Sample name | 1st stage | 2nd stage | 3rd stage | 4th stage | Residual weight % | ||

|---|---|---|---|---|---|---|---|

| 30°C-100°C Wloss (%) | Trange (°C) | Wloss (%) | Trange (°C) | Wloss (%) | 498°C-600°C Wloss (%) | ||

| R2 | 0.851 | 100-269 | 1.94 | 269-518 | 89.55 | 90.88 | 0.1 |

| S2 | 0.403 | 100-312 | 2.1 | 312-500 | 99.09 | 100 | 0.29 |

| A2 | 0.243 | 100-312 | 1.77 | 312-498 | 99.31 | 99.67 | 0.37 |

| C2 | 0.425 | 100-312 | 2.29 | 312-511 | 100 | 100 | 0.44 |

Note: Where, Trange stands for temperature range and Wloss for weight loss

Table 3: Detailed thermal decomposition values of woven jute and glass fiber reinforced PCL composites.

Composites morphology analysis

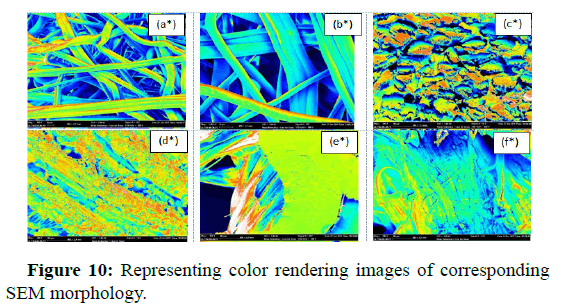

Surface morphology of woven jute and glass fiber reinforced PCL composites displayed in Figure 9. As demonstrated in Figure 10 representing the glass fiber in 2 μm whereas showing the close look of glass fiber in 10 μm. SEM morphology exhibiting the cross-sectional view of woven jute which also demonstrates the stiffness of composites. Micrograph revealed that due to chemical modification PCL grafted properly into the surface of jute fibers that is an indication of better adhesion of fiber with matrix. Subsequently, the surface of wet-laid glass fiber was changed due to hot pressing pressure and temperature which can be observed. Moreover, micrograph Figure 11 representing color rendering images of corresponding SEM morphology.

Conclusion

In the present experiment, woven jute and glass fiber reinforced PCL composites fabricated using the hot-pressing method where jute used as a sandwich with upper and lower glass fiber sheet with PCL as a matrix. The experiment conducted to see the effect of chemical treatment as well as find the best parameter hot pressing temperature, pressure and time for the composites. As demonstrated, alkali and silane combined treated optimized sample C-2 exhibited enhanced tensile strength and modulus with reduced impact strength. Surface chemistry analyzed using FTIR and observed fiber modification over untreated fiber. Mechanical properties of this composite influenced by interfacial adhesion between fiber and matrix as substantiated after observing morphological structures with a Scanning Electron Microscope (SEM).

Mechanical properties like tensile and impact strength investigation performed to find the consequence after chemical treatment from the woven jute fabric resulting in 48.38%, 32.04% improved in tensile strength and modulus with 39.58% reduced impact strength in alkali silane combined treated composite over untreated optimized composites. Better fiber-matrix interfacial adhesion resulting in improved thermal stability of combined treated composite over alkali, silane and untreated composites jute glass fiber reinforced PCL composites. Eventually, a 165°C temperature, 7 MPa pressure and 9 minutes of heat pressing with 6 minutes colling can consider as a suitable parameter for this composite to produce outstanding lightweight woven jute and glass fiber reinforced PCL composites.

References

- Arbelaiz A, Fernandez B, Valea A, Mondragon I (2006) Mechanical properties of short flax fibre bundle/poly (ε-caprolactone) composites: Influence of matrix modification and fibre content. Carbohydr Polym 64: 224-232.

- Sarasini F, Tirillo J, Puglia D, Dominici F, Santulli C, et al. (2017) Biodegradable polycaprolactone-based composites reinforced with ramie and borassus fibres. Comp Struct 167: 20-29.

- Rafiquzzaman M, Islam M, Rahman H, Talukdar S, Hasan N (2016) Mechanical property evaluation of glass jute fiber reinforced polymer composites. Polymer Adv Technol 27: 1308-1316.

- Cheung HY, Ho MP, Lau KT, Cardona F, Hui D (2009) Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Composite Part B Eng 40: 655-663.

- Chen Y, Chiparus O, Sun L, Negulescu I, Parikh DV, et al. (2005) Natural fibers for automotive nonwoven composites. J Ind Text 35: 47-62.

- Hassan ML (2003) Recycling of jute textile in phenol formaldehyde jute composites. J Appl Polym Sci 90: 3588-3593.

- Orue A, Jauregi A, Pena-Rodriguez C, Labidi J, Eceiza A, et al. (2015) The effect of surface modifications on sisal fiber properties and sisal/poly (lactic acid) interface adhesion. Engineering 73: 132-138.

- Luo S, Netravali AN (1999) Interfacial and mechanical properties of environment-friendly “green” composites made from pineapple fibers and poly (hydroxybutyrate-co-valerate) resin. J Mater Sci 34: 3709-3719.

- Sawpan MA, Pickering KL, Fernyhough A (2012) Flexural properties of hemp fibre reinforced polylactide and unsaturated polyester composites. Composite Part A Appl Sci Manufactur 43: 519-526.

- Wang H, Memon H, AM Hassan E, Miah MS, Ali MA (2019) Effect of jute fiber modification on mechanical properties of jute fiber composite. Materials 12: 1226.

[Crossref] [Google Scholar] [PubMed]

- Kumaar AS, Senthilkumar A, Saravanakumar SS, Senthamaraikannan P, Loganathan L, et al. (2022) Mechanical properties of alkali-treated Carica papaya fiber-reinforced epoxy composites. J Natur Fiber 19: 269-279.

- Jarukumjorn K, Suppakarn N (2009) Effect of glass fiber hybridization on properties of sisal fiber-polypropylene composites. Composite Eng 40: 623-627.

- Velmurugan R, Manikandan V (2007) Mechanical properties of palmyra/glass fiber hybrid composites. Appl Sci Manufactur 38: 2216-2226.

- Huq T, Khan A, Noor N, Saha M, Khan RA, et al. (2010) Comparative studies on the mechanical, degradation and interfacial properties between jute and E-glass fiber-reinforced PET composites. Polymer-Plastic Technol Eng 49: 1128-1135.

- Adhikari RK, Gowda BK (2017) Exploration of mechanical properties of banana/jute hybrid polyester composite. Mater Today Proceed 4: 7171-7176.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi