Research Article, J Nucl Ene Sci Power Generat Technol Vol: 11 Issue: 5

Electricity Management for Building in Summer Using Smart Grid Technology Concept: A Case Study at University Of Phayao, Thailand

Nuttanon Pongpanit1 and Bunyawat Vichanpol2*

1Department of Mechanical Engineering, School of Engineering, University of Phayao, Thailand

2Department of Renewable Energy, School of Energy and Environment, University of Phayao, Thailand

*Corresponding Author: Bunyawat Vichanpol, Department of Renewable Energy, School of Energy and Environment, University of Phayao, Thailand E-mail: bunyawat.vi@up.ac.th

Received date: 22 November, 2021, Manuscript No. JNPGT-21-47987; Editor assigned date: 25 November, 2021, PreQC No. JNPGT-21-47987 (PQ); Reviewed date: 09 December 2021, QC No. JNPGT-21-47987; Revised date: 22 January 2022, Manuscript No. JNPGT-21-47987 (R); Published date: 01 April 2022, DOI: 10.4172/2325-9809.1000273

Citation:Vichanpol B, Nuttanon P(2022) Electricity Management for Building in Summer Using Smart Grid Technology Concept: A Case Study at University Of Phayao, Thailand. J Nucl Ene Sci Power Generat Technol 11:5.

Abstract

The study demonstrates an improvement guideline for building energy management using photovoltaic under the smart grid technology concept, aimed at reducing peak demand of the summer in Thailand. The Faculty of engineering building at University of Phayao, located in Phayao province, was a case study area. The improvement guideline was applied by operating the Battery Energy Storage System along with Demand Side Management. The results of using only selfenergy production revealed that the self-consumption was increased from 78.89% to 94.27% while the peak demand could be decreased from 75.36% to 41.04%.

Keywords: Building energy management, Photovoltaic, Peak demand, Battery energy storage system, Demand side management

Introduction

Thailand's electricity demand has risen dramatically from 20,538 megawatts of peak demand in 2005 to 30,853 megawatts in 2019, while overall electricity production has doubled from 26,450 megawatts to 43,253 megawatts [1]. Annual peak demand occurs in the summer, between March and June, when solar radiation potential is greatest. According to 2017 data on sub-district solar radiation, Phayao province, which was used as a case study area, receives an average daily solar radiation of approximately 19 to 21 MJ/m2-day, which means that the air conditioning system in the building absorbs more electricity than Photovoltaics (PV) can produce.

Currently, electricity consumption design in medium and large buildings is complicated according to area and users compared to a small building. Therefore, energy saving building presents a greater challenge. Even if the PV system is fully installed, it would not be able to satisfy the electricity demand of users in the building. Previously, building design in Thailand did not consider energy consumption and energy saving in buildings, resulting in inefficient energy consumption in a large number of old buildings. Building Energy Management System (BEMS) should be considered when developing and redesigning the energy consumption system. BEMS is an efficient energy management system that optimizes energy consumption by preventing or minimizing energy use in the building, but the system will not operate over the limits of the building and effect on users’ health. BEMS with a Smart Grid System called SG-BEMS Model was applied to link the alternative electricity from renewable energy to the grid with stability and capability. Additionally, this model is capable of adjusting the primary control center for energy demand in a building, responding to demand, and increasing the electricity system's versatility. As mentioned earlier, this model could thus contribute to a decrease in overall energy consumption in buildings.

The aim of this study is to demonstrate an improvement guideline for building energy management using photovoltaics within the context of the smart grid technology concept, with the goal of lowering summer peak demand in Thailand. The case study area was the Faculty of Engineering building at the University of Phayao in Phayao province.

Objective and scope of the study

In this work, data from the Smart Grid UP system was evaluated to establish a guideline for energy management in building integrated PV system for solving the high energy demand in summer of the EN2-EN3 prototype building at University of Phayao.

Materials and Methods

An evaluation of power demand and supply pattern in prototype building

Although it has the highest peak demand in the summer, it also has the highest electricity production from PV. Hence, the high electricity output from PV can cover summer's excess energy demand [2]. However, the relationship between collected data of energy demand and energy supply from Smart Grid up over the course of a day showed an inconsistent with each other as shown in Figure 1, resulted in an inefficient energy usage in the prototype building. The data was collected from roof-top PVs with a capacity of 60 kWp and the building's energy demand every 10 minutes between 7:00 and 18:00 on May 2, 2017.

Figure 1:Energy supply and demand pattern of a prototype building.

Summer electricity generation from photovoltaics began at 7:00 am while energy consumption activity in buildings began at 8:00 am Between 7:00 and 13:00 on the test day, energy supply from PV generation surpassed energy demand by approximately 74.30 kWh; however, this equated to an energy loss of approximately 27.71 percent of daily electricity production [3]. This trend showed an inefficient energy management system that failed to balance demand and supply. The relationship between electricity generation from Smart Grid Up (Active Power) and the building's energy demand was plotted in Figure 2 at various times of the day.

Figure 2:The plot between electricity generation from Smart Grid Up (Active Power) and energy demand of the building.

According to the preliminary test results shown in Figures 1 and 2, there was a substantial fluctuation in solar energy generation capability. Also due to weather conditions which is unconnected to the solar radiation that rapidly changes, in intensity [4]. This results in a change in the level of electrical power generated related to the primary factor influencing power generation, which is the strength of solar radiation and the temperature of the solar panel. The solar panel's high temperature will result in a decrease in power generation efficiency. Figure 3 depicts the transition in the data collection. According to the data, the primary source of electrical power consumption is air conditioning, which is a function of the thermal load outside the building and thermal mass. This issue resulted in the building retaining heat and accumulating moisture at building framework. Thus, only the shift in temperature outside cannot influence energy demand in buildings [5].

Figure 3: The relationship between solar radiation and PV module temperature.

As previously illustrated, preliminary studies of energy consumption in a prototype building were shown in Figures 1, 2, and 3. As a result, it was determined that the air conditioner system consumed approximately 86.94 percent of the energy available at 1,500,265 Btu/hr. The system's maximum energy demand was estimated to be at least 139.15 kW. While the lighting system consumed 8.06%, the other systems consumed less than 5%, indicating that this was a low-energy-demand building. Thus, the primary objective of this work was to develop guidelines for energy management systems in buildings that utilize air conditioners as the primary energy consumption system. This guideline is divided into two sections: (1) an examination of the energy performance and production of solar panels with Smart Grid UP in May 2017, the month with the highest energy demand in Thailand; and (2) the establishment of an appropriate management protocol and cost reduction.

Assessment of solar energy production performance and pattern from Smart Grid UP

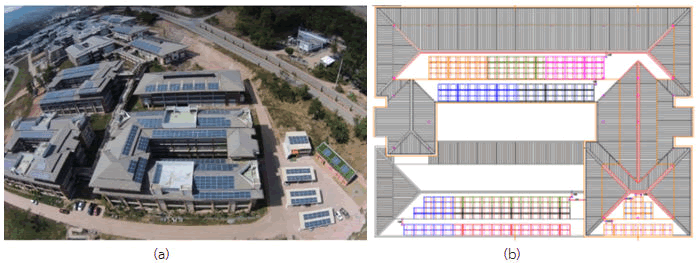

Solar energy systems totaling 500 kW were installed on the roofs of all 11 buildings. This study focused exclusively on the prototype building (EN3-4) that has installed a 60-kW PV system. The system's main component is a polycrystalline silicon solar panel (SHARP, model ND-AA 250) and an inverter (SMA brand, model STP25000TL-30), as illustrated in Figure 4.

Figure 4: PV module installation and PV module outline on the roof of EN3 and EN4 building; (a) Photograph from drone and (b) Drawing of prototype building from AutoCAD File.

In May 2017, data from the Smart Grid UP system were recorded and collected. It contains information about the generation of electricity, the amount of solar radiation, and the temperature of the PV panel. Following that, these data were used to create a simulation model of PV energy production potential in order to forecast power output at various times during clear skies (estimated from solar radiation intensity >10 hours over 500 W/m2). This enables estimation of the average amount of electric power generated during the study area's operation from 7:00 to 18:00. The relationship between produced power (Pe) and solar radiation intensity is dependent on the estimated solar panel temperature, as shown in equation 1 [9].

Pe=a+bIT+cIT2+dTm+eITTm+fIT2Tm (1)

Where IT is solar radiation intensity and Tm is the temperature of the PV panel.

An energy management system in the building appropriation with energy consumption

The purpose of this section is to identify a suitable energy management model within the framework of the smart grid technology concept, which was divided into two parts. The first part examines methods for optimizing the use of electric energy in order to increase the energy efficiency of the prototype building with existing air conditioning systems and thus reduce overall system power demand and usage. The latter part was a study how excess electricity (over energy) is utilized between the hours of 7.00 and 13.00. According to preliminary findings, excess energy could account for up to 25% of total power generation. Thus, the results of this section were used to determine the appropriate size of the Battery Energy Storage System (BESS) as a backup power source in energy management in order to reduce peak power demand during the day and reduce electricity consumption from the lighting system at night or on holidays.

Results and Discussion

Results of power generation potential and pattern using Smart Grid UP

The relationship between the energy produced and the average daily solar radiation intensity during the interesting month was observed using data from the daily power production potential, as shown in Figure 5. For May 2017, the average electricity production was 259.12 kWh/day, based on an average solar radiation intensity of 464.98 W/m2. According to the data, there were fluctuations in the capacity of electricity and the intensity of solar radiation. As a result, data demonstrating that the average solar radiation intensity was consistently greater than 500 W/m2 on clear sky days in May 2017 were used to assess the power generation potential, as illustrated in Figures 6 and 7. Additionally, the power generation ratio, the intensity of solar radiation, and the temperature of the panel were all considered.

Figure 5: Electricity generation and average daily solar radiation of May 2017.

Figure 6: A graph of relationship between PV module temperature and solar radiation.

Figure 7: Electricity from Smart Grid Up (Active Power) and solar radiation.

Additionally, the study discovered that the correlation between solar intensity and solar panel temperature was direct. This pattern was associated with two distinct time periods: 07.00-13.00 and 13.00-18.00. After 1 pm the differences occurred due to the accumulation of heat in the panel caused by solar radiation and the effect of the increasing of ambient temperature, which is hotter than in the morning. Figure 8 depicts the two relationships and explains them using the following equations:

07.00-13.00; Tm=(-2x10-5)IT2+0.0606IT+20.544; R Square=0.9852……………………(2)

13.00-18.00; Tm=(-2x10-5)IT2+0.0443IT+29.106; R Square=0.9837……………………(3)

Figure 8: The relationship between solar radiation and PV module temperature.

Rising temperatures resulted in an increase of approximately 0.07 percent/K in short circuit current (Isc), while the open circuit voltage (Voc) decreased by approximately 0.4%/K. As a result, power output reduced by 0.4-0.5 percent. Then, after evaluating the data set for May 2017, it was determined that the relationship between the produced power (Pe) and the intensity of solar radiation and the temperature of the solar panel as equation (4).

Pe=0.2436 IT-0.493Tm-0.00286ITTm……………… (4)

Where, regression statistics at R Square equals to 0.9699773, adjusted R Square is 0.969173, Standard Error=6.4629445 from Observations=1321. Following simulation using equation (4), Figure 9 compares the simulated data to the actual value.

Figure 9: Electricity generation potential and Active power from Smart Grid UP for 2 days.

The prediction of solar energy supply using the Smart Grid UP system demonstrated that it gave an accurately prediction and has a high degree of reliability during the prediction time period of 07.00-13.00 under constant solar exposure conditions, normal panel temperature, and surplus solar energy produced by PV is greater than the building's needs in contrast, after 1 pm the impact of heat accumulation on PV panels resulted in panel temperatures exceeding 45°C, rendering the forecast highly erroneous. As a result of evaluating the relationship described in Equation (4) in conjunction with the building's electric power consumption trends, it was determined that the excess electricity generated by PV in May averaged 66.18 kWh/day, or 21.11 percent of total electricity generation.

Results of energy management system which appropriate for energy consumption

Guideline of electricity consumption improvement: In general, the building system is comprised of electrical energy used for climate control in various areas of the building, referred to as Heating Ventilation and Air-Conditioning (HVAV), which accounts for more than 50% of the building's overall energy consumption [6]. According to this analysis, HVAV accounted for 85 percent of the total energy consumption in a prototype building. Consequently, the average daily peak demand in May 2017 was 59.63 W/m2, which occurred between 13:30 and 16:30, and the average daily power demand was 48.15 W/m2. The following factors contribute to low energy efficiency:

- The actual air conditioning system configuration incorporates a greater than sufficient allowance for heat load, resulting in the total system being installed at 1,500,265 Btu/hr. The real installation Btu is 48.02 percent more than the calculated value.

- Since the air conditioning system is modular and each area is operated independently by a local thermostat, it is difficult to control energy consumption to achieve optimum efficiency.

Due to the issues that occur, the study developed test energy management models specifically for air-conditioned areas in order to assess energy capacity use. The test area was equipped with a chilled water air conditioning system consisting of an Air-Cooled Chiller (ACC) with a Coefficient of Performance (COP) of 3.1 at 7.753 kW, R-22 as refrigerant, a chilled water pump with a capacity of 0.87 HP, and an Air Handling Unit (AHU) capable of supplying cool air at a maximum flow rate of 3,200 ft3/min (Figure 10).

Figure 10: A Chilled water for air conditioning system (1) Air-cooled chiller, (2) Chilled Water Pump and (3) Air Handling Unit.

Based on the concept of the SG-BEMS model, a sensing device was developed to collect data on energy demand on the floor in order to monitor and modify the electrical load of the air conditioning system, resulting in load response (Demand Response). The aforementioned methodology is used to develop Demand-Side Management (DSM) method for managing the area's air conditioning systems [7]. The ARDUINO Model MEGA 2560 R3 controller and temperature and humidity sensor package (THD series, Autonics) were chosen to monitor chilled water systems that matched the actual heat load inside the test chamber as shown in Figure 11.

Figure 11: A photograph of ARDUINO Board Model MEGA 2560 R3 system and temperature, and outdoor and indoor humidity.

To obtain a more precise value of the sensor, a PID cooling water consumption rate control is used in combination with the original air conditioner's On/Off control. This section's equipment includes a 3-Way Valve (1-1/2 ", Azbil) in conjunction with a flow control unit or electromechanical actuator as shown in Figure 12.

Figure 12: Three-way flow control valve from Asbil.

Initially, 1,000 lite chilling water in tank was held at a temperature around 7°C. The chiller operates between 06:00 and 07:00, because the building is not in service, but the test was conducted only during service time. Figure 13 illustrates the contrast power demand profile without DSM system (Day 1) and power demand profile after installed DSM system (Day 2) during 12: 00-16: 00.

Figure 13: Energy management results. Day 1: Power demand profile without DSM system and Day 2: Power demand profile after installed DSM system.

Following retesting and data collection were done. It was determined that the average daily maximum power demand per unit area of the study in the prototype building in May decreased from 58.03 W/m2 to 36.45 W/m2 or 37.25 percent. When the average reduction in power demand per unit area during the period 11.00-6.00 hrs was calculated, it was found to be 18.52 W/m2, which resulted in a decrease in the building's average electricity consumption during that period of approximately 0.015 kWh/m2 (assessment includes the power demand and the electric energy consumption of the chiller) [8].

The findings of this study can be used to develop a method for managing electricity demand. This is one method for enhancing a building's control system that is already in place. A well-designed control system can maintain an optimal balance of room temperature and energy usage, reducing power consumption by approximately 25% as compared to traditional systems.

Surplus electricity utilization: Surplus electricity produced by the load has two potential uses. To begin, surplus electricity can be sales, which can now be made at a non-burden rate of approximately 1.68 baht per kWh for self-electricity production for personal use (Refer to the Energy Regulatory Commission's (ERC) document: Details of the solar project for the year 2019 (residential type)). In this article, it is assumed that there is no additional investment required for system installation. The latter option is to store the energy in a battery, with the stored electrical energy being used during the day's peak demand time. For the building on an opening semester (Monday-Friday), the electricity cost was calculated at the time of use rate (TOU), while the holiday (off-peak duration) use electricity from the storage system to power loads from other facilities, such as lighting and other building systems, at an average cost of 4.2097 baht/kWh with a demand charge of 132.93 baht/kW during the off-peak time at a cost of 2.6295 baht/kWh. There are 116 off-peak days in 2019 (refer to the Provincial Electricity Authority's statement on Off-Peak Days for the 2019 cost TOU year).

The preliminary findings described in Section 4.1 regarding the study of the prototype building's excess energy in May were then used to create a relationship between power demand and the system's active energy, as illustrated in Figure 14.

Figure 14: Power demand pattern of the building and electricity generation from Smart grid UP (Active energy).

The generated energy can be classified into two categories: direct electricity to loads (self-consumption) and excess energy (Over energy) [9]. As a result, it was determined that the peak electricity production time of the day occurred between 9.00 and 12:00, allowing for the use of this data to construct a BESS system for power management in the event of a particular load-side excess power (Figure 15).

Figure 15: Surplus energy during 8.30-13.00.

As a result, in May, the Smart Grid UP system was used in conjunction with the electric energy demand model to ensure that energy generated was used efficiently and in accordance with the BESS system's investment. This model was used between 09.00 and 11.30 for battery charging with a maximum capacity of 45 kWh due to the continuity of electric power at the desired time from little fluctuation in input current and potential and a limited surplus energy. Power management utilizes battery power to power the load during peak hours on weekdays and traditional power during holidays, which have significantly different energy yields. The results of this study were primarily focused on building usage and the On-Peak range, with the simulation results illustrating the relationship between direct load power generation and BESS integration. The prototype building's energy demand is depicted in Figure 16.

Figure 16: Relationship between power generations operating, BESS and power demand pattern of prototype building.

Parts 4.2.1 and 4.2.2 provide data that can be used to enhance strategies and joint systems for photovoltaic-powered buildings. The effects of the pre and post-renovation power demand patterns are depicted in Figure 17.

Figure 17: Relationship between power generations by DSM operating with BESS and electricity demand pattern of prototype building.

When combining energy conservation steps such as DSM and BESS, the overall daily energy demand can be held below 50 kW. According to the study's findings in Figure 14, the overall daily power demand was approximately 10% lower than the consumption of the PV system with BESS alone. As a result, the study's findings can be summarized in Table 1.

Table 1: Energy management results of EN3-4 building using Smart Grid UP (at PV 60 kWp).

The study's findings on how to improve building energy management, as well as the potential for photovoltaic power generation in conjunction with the principle of smart grid technology, in order to minimize summer peak electric power demand. Solar radiation intensity had the potential to influence the ability of electricity and electric power generation, as well as the patterns of building electric power use. These two fundamental pieces of information, which vary according to area and application, can be used to develop energy management practices that are highly efficient. An analysis of the Smart grid UP system in a summer prototype building that uses grid power in combination with PV discovered direct load power generation. (Self-consumption) was just 247.35 kWh, or 78.89 percent of total capacity for electricity generation. During an overproduction time, it was determined that the excess electric energy had the capacity to charge the battery at 48.22 kWh for the BESS device. When the system was simulated, it was revealed that the produced energy consumption increased to 295.56 kWh or 94.27 percent of the system's total power generation capability. Furthermore, when improving the model of energy consumption for air conditioning, it was observed that the simulation of the energy consumption system is more effective. When evaluating the effectiveness of energy management in accordance with the above guidelines, an energy efficiency gain of approximately 10,942.88 baht (May only) can be calculated as a result of the reduction in electricity demand (Demand charge) at 41.36 kW or 5,498.49 baht and the effect of lower energy consumption during the on-peak period of 6,434.69 baht and the off-peak period of 6,434.69 baht [10].

Conclusion

According to an analysis of prototype buildings-integrated PV, energy requirements decreased by 11.63 percent as linked to the optimized BESS system design. The DSM system's controls minimize energy usage by 5.13 percent, with the maximum peak demand level reduced by 34.32 percent as associated with direct load alone. It can be summarized as follows as a study guideline.

A design approach that enables efficient energy management between grid-connected and pv power includes a master database that contains information about the solar capacity of the location and the electrical consumption patterns of the building. This is critical knowledge for investors when determining the optimal size of photovoltaic panels for actual use. It is mainly focused on direct loading, which generates a higher return per unit than device resale. The building's utilization pattern has an effect on the electric power consumption patterns in two related areas, which is critical for sizing the BESS device appropriately, avoiding the need to choose an overcompensated system for energy storage, which would increase the investment cost more than required.

Through the use of the DSM system as a critical component of the smart grid solution, the technology would be able to monitor the level of electrical load, thus improving energy efficiency and allowing the reduction and balance of energy supply to both energy demand and generated energy. Additional investment can be made in existing buildings that have already been constructed and can easily be converted for less complex usage. Further research would be driven by the potential for change and economic return.

Return on investment analysis did not include in the scope of this research. Additional study recommendations include an estimation of BESS's primary equipment expenditure, which is the substantial cost of the battery type. Two types of batteries are now preferred: lead-acid and lithium-ion. The latter offers superior features and is cheaper in the current period. Another factor influencing yield thinking is the government-determined electricity cost structure and resale rate, as well as the policy. From the determination of the electricity tariff in 2018 in accordance with the measure to encourage energy conservation (Demand Response Rate) (refer to the Thailand Smart Grid Network Development Master Plan 2015-2036), which resulted in an investment decision opportunity, either to build additional photovoltaic systems or to scale-up BESS.

Data Availability Statements

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Acknowledgements

The authors express their gratitude to School of Engineering, University of Phayao, Thailand for supporting the building use as prototype in this experiment.

References

- Chanikarn Y (2013) Energy efficient measures for buildings with grid-connected photovoltaic systems located in Bangkok, Thailand. Appl Mech Mater 361: 224-230.

- D Murayama, K Mitsumoto, Y Takagi, Y Iino, S Yamamori (2012) Smart grid ready BEMS adopting model-based HVAC control for energy saving. Transm Distrib Conf Expo 1-6.

- Bayindir R, Colak I, Fulli G, Demirtas K (2016) Smart grid technologies and applications. Renew Sustain Energy Rev 66: 499-516.

- Skoplaki E, Palyvos JA (2009) Operating temperature of photovoltaic modules: A survey of pertinent correlations. Renew Energy 34: 23-29.

- Guido Lorenzi, Carlos Augusto Santos Silva (2016) Comparing demand response and battery storage to optimize self-consumption in PV systems. Appl Energy 180: 524-535.

- Sadeghi H, Toghraie D, Moazzami M, Rezaei MM, Dolatshahi M (2022) Integrated long-term planning of conventional and renewable energy sources in Iran's off-grid networks. Renew Energy 182: 134-162.

- KC KB (2011) Assessing strategic water availability using remote sensing, GIS and a spatial water budget model: case study of the Upper Ing Basin, Thailand. Hydrol Sci J 56: 994-1014.

- Intriago Zambrano JC, Michavila J, Arenas Pinilla E, Diehl JC, Ertsen MW (2019) Water lifting water: a comprehensive spatiotemporal review on the hydro-powered water pumping technologies. Water 11: 16-77.

- Kiguchi M, Takata K, Hanasaki N, Archevarahuprok B, Champathong A (2021) A review of climate-change impact and adaptation studies for the water sector in Thailand. Environ Res Lett 16: 023004.

- Ongate N (2021) Prototype design of solar soil moisture controller to be used as an alternative energy for agriculture against the growth of vegetables in Khao Kho district, phetchabun province. SNRU J Sci Tech 13: 20-28.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi