Research Article, J Fashion Technol Textile Eng S Vol: 0 Issue: 4

Development of a Universal Solar Energy Harvesting System Suited for Textile Integration Including Flexible Energy Storage

Kuhlmann JC1*, de Moor HHC2, Driesser MHB2, Bottenberg E1, Spee CIMA2 and Brinks GJ1

1Saxion University of Applied Sciences, Academy Creative Technology, Research group Smart Functional Materials, Enschede, Netherlands

2Avans University of Applied Sciences, Centre of Expertise for Sustainable Innovation, Research group Solar Production Technology and Equipment Development, Breda, Netherlands

*Corresponding Author : Jan-Carlos Kuhlmann

Saxion University of Applied Sciences, Academy Creative Technology, Research group Smart Functional Materials, Enschede, Netherlands

Tel: +31 62 506 5511

E-mail: j.c.kuhlmann@saxion.nl

Received: December 11, 2017 Accepted: February 27, 2018 Published: March 02, 2018

Citation: Kuhlmann JC, de Moor HHC, Driesser MHB, Bottenberg E, Spee CIMA, et al. (2018) Development of a Universal Solar Energy Harvesting System Suited for Textile Integration Including Flexible Energy Storage. J Fashion Technol Textile Eng S4:012. doi: 10.4172/2329-9568.S4-012

Abstract

With the growing interest in smart textiles the need for a lightweight energy supply that is compatible with textile properties is increasing. Here we describe a proof of concept for a universal solar harvesting system which is scaled for the integration into clothing including flexible energy storage and flexible solar cells. The flexible solar cells show efficiencies of above 10 % and are integrated as individual strips in order to minimize the effect on the bending and draping properties of the textile. The integrated batteries are lithiumion based and include an electrolyte that guarantees safety when in proximity to the human body.

Keywords: Smart textiles; Solar cells; Batteries; Energy

Introduction

This work is part of the ongoing Dutch RAAK PRO research project TexEnergie [1]. Within this project the goal is to explore the feasibility of the integration of energy generation and storage within textiles. The framework of this project is defined by the participating companies that are interested in the possibilities of solar generation in their textile product range. This results in a broad application field that ranges from workwear, to sportswear, to defence application, over to technical textiles for agriculture applications or sun shading. In order to be able to explore the feasibility of such systems we defined different concepts based on the dimension of the system. This conference paper describes the material and design considerations towards the fabrication of a proof of concept demonstrator for small scale applications, such as the integration in clothing.

System Design

The complete energy generation and storage system has been divided into subsystems in order to find suited components and to further improve each subsystem. These subsystems are energy generation, energy storage, interconnection, and electronics. A requirement for all subsystems is the use of technically mature and commercially available components that ensure a high technical readiness level of the resulting demonstrators. With the development of systems like the one foreseen here combining harvesting, storage, and incorporation of the required control technology is complex. Meeting utility and safety requirements is only possible with rigorous application of the principles of systems engineering [2]. This process further ensures to comply with the differing end-user requirements. For this reason, systems engineering is an important part of this research project. In this paper, however the emphasis is on showing the proof of principle with a strong focus on component selection and testing the basic functions.

Solar cell

Besides a high efficiency the most important requirement for the solar cells is the flexibility. Although there a lot of very promising developments in the field of flexible solar cells such as organic solar cells and perovskite solar cells with power conversion efficiencies (PCE) above 10 %, these technologies have not entered the market yet [3]. Therefore, we used amorphous silicon and flexible copper indium gallium selenide (CIGS) for our studies. Amorphous silicon solar cells are commercially available in many different form factors and show a good performance in low light conditions. However, the overall PCE is in the range of 3 to 5 %. Besides the integration in solid solar modules, the CIGS technology is also applied to flexible substrates. Typical PCEs are in the range of 10-15 %. Both types of solar cells can be directly laminated onto textile materials by using thermoplastic polyurethane (TPU) foils.

Battery

In order to ensure a secure a safe product the integrated battery should not contain corrosive materials that could leak upon malfunction of the system. Furthermore, especially for clothing application the integration of a flexible battery could reduce the footprint of the electronic system. Nowadays, most lithium-based batteries are not flexible and contain corrosive electrolytes, which make them not the first choice in this project. Recently several examples of lithium-based batteries were demonstrated that are flexible and contain solid non-corrosive electrolytes, but these developments are not commercialized yet [4,5]. Another import aspect is that the electronic properties of the battery are compatible with the maximum current that can be provided by the solar cells and the current that is needed for the application.

Interconnection

A variety of conducting textile materials has been introduced to the market in recent years. Unfortunately, in many examples the electrical resistance is rather high, which limits the applicability these materials for smart textile applications. In order to ensure a safe system that can be worn on the skin, the interconnections should be isolated and should not increase temperature. As a general rule, wearables that are in contact with the human skin should not rise more than 2Ã?Â?C above body temperature, thus not higher than 39Ã?Â?C. The upper limit for medical electronic equipment in contact with the human skin is 43Ã?Â?C as the skin is damaged at temperatures above [6,7].

Control electronics

The control electronics in the system should fulfil several essential functions, such as optimizing the solar cell performance by using a maximum power point tracker, controlling the charge and the discharge of the battery and monitor the generated, the available, and the consumed energy. Different devices that control the energy generation, storage and usage are commercially available and will be investigated for their use in the system. The read-out electronics have a lower priority in this project and will be based on an Arduino system with an own power supply.

Proof of Concept

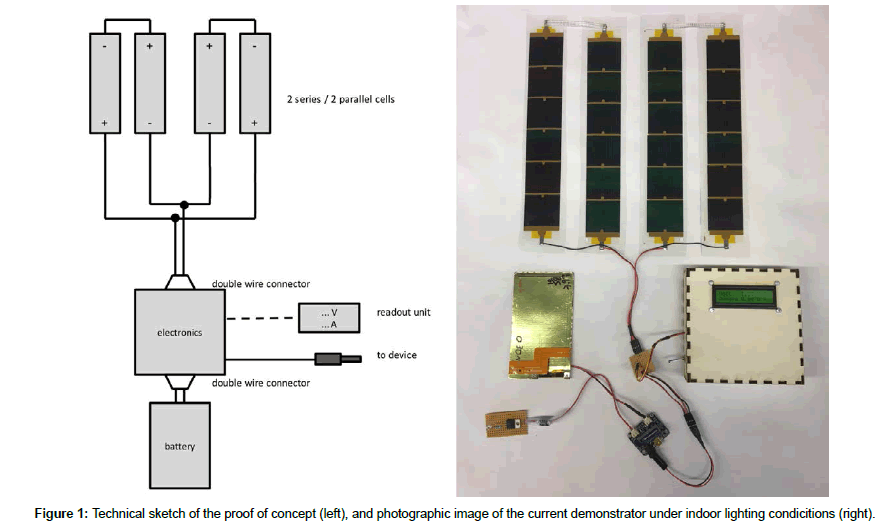

In consideration of the first mainly exploratory results a first proof of concept for small-scale application e.g. for clothing, was designed and fabricated. Individual stripes of flexible CIGS solar cells (295 x 44 mm) were laminated onto a fabric using TPU foil. The total active area covered with solar cells is approximately 500 cm2. Two stripes were connected in series which were connected two another pair in parallel configuration. As a connector for the series connection a conductive fabric ribbon which consists of three conductors containing of stranded tinsel wires (total 68 wt% stranded tinsel wires, 32 wt% polyester). This textile conductor shows a low resistance of 0.3 Ω/m. In order to keep the ohmic losses low, all three wires where used for one connection. The connections to the other electronic device were realized by using isolated stranded copper wires. In upcoming iterations of this demonstrator these wires will be replaced by textile based conductors.

The energy generated by the solar cells can be stored with lithium-based batteries that are flexible and contain a ceramic electrolyte which replaces the ordinary harmful materials. These solid-state lithium batteries have a thickness of 0.4 mm, are flexible, and show a capacity of 235 mAh at a voltage of 3.75 V. The further dimensions are 73 × 130 mm. According to the specification this battery type is suited to be charged and discharged at rates up to 1C. However, charging/ discharging tests showed that a stable performance is ensured at rates between 0.2C and 0.5C. Newer improved versions of these batteries have been developed, but these are not available yet. In order to be able to react to charges of up to 0.5 A generated by the solar cells, a stack of five batteries connected parallel were included in the demonstrator.

The current demonstrator is controlled by an Adafruit Solar Battery charger (MCP73871) which controls the and the battery charge management. In order to control the energy that is generated by the solar cells a read-out unit based on an Arduino board with a separate power supply is attached.

The individual devices in this demonstrator are connected using either flat FCC or JST connectors in order to be able to exchange parts for testing. A technical sketch and a photograph of the first-generation prototype are shown in Figure 1.

Preliminary experiments showed that the solar cells are able to generate 7.0 V and 0.45 A (3.15 W) in direct sunlight with an intensity of roughly 100 000 lx. This energy was sufficient to charge the battery and drive a LED which was attached as a demonstrator load. When tested indoor under fluorescent office lighting with a light intensity of about 500 lx, the performance decreased to 1.2 V and 0.04 A (0.05 W).

Conclusions

In conclusion, we designed and developed a proof of concept for energy generation and storage integrated in textiles. The first experiments on the performance of the solar cells show a good performance of 3.15 W which is higher than the estimated performance solely bases on the specifications of the solar cells. The measured indoor performance was much lower, which is in accordance with the highly decreased light intensity and the narrowed spectra of the light source. The following steps will focus on improved textile integration and the quantification of the overall system performance.

Outlook

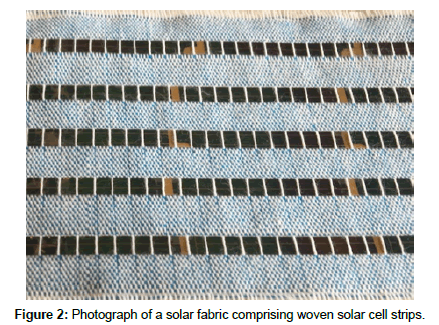

It should be clear from the foregoing that the ambition to integrate both harvesting and storage technology into textiles is an ambitious goal. As discussed above, elements of systems engineering will be applied to further develop demonstrators based on end user requirements. In this preliminary report, we did show that thin flexible systems can be achieved. However future work will also involve weaving of strips of carefully cut solar cells into textiles. Preliminary tests have shown that this is feasible and details of this work will be reported in due time. Figure 2 shows a photograph of woven solar cell strips which will be integrated into the prototype described in this work.

References

- Texenergie (2017) Energy collection and storage in textiles.

- Walden DD, Roedler GJ, Forsberg KJ, Hamelin RD, Shortell TM (2015) INCOSE systems engineering handbook: a guide for system life cycle processes and activities. (4th edtn), John Wiley and Sons, Inc., Indianapolis, USA.

- Green MA, Hishikawa Y, Warta W, Dunlop E, Levi D, et al. (2017) Solar cell efficiency tables (version 50). Progress in Photovoltaics: Research and Applications 25: 668-676.

- Panasonic (2016) Panasonic develops bendable, twistable, flexible lithium-ion battery.

- Jenax (2016) Flexible lithium polymer battery.

- International Organization for Standardization (2015) IEC 60601-1-11:2015 - Medical electrical equipment--Medical electrical equipment -- Part 1-11: General requirements for basic safety and essential performance -- Collateral standard: Requirements for medical electrical equipment and medical electrical systems used in the home healthcare environment.

- Moritz AR, Henriques FC (1947) Studies of thermal injury: II. the relative importance of time and surface temperature in the causation of cutaneous burns. Am J Pathol 23: 695-720.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi