Research Article, J Fashion Technol Textile Eng Vol: 8 Issue: 6

Comprehensive Drafts of Woven Fabrics

Oghale OO1* and Oluwafunmilayo OL2

1Department of Fine and Applied Arts, Delta State University, Abraka Nigeria

2Department of Fine and Applied Arts, Ambrose Alli University Ekpoma, Edo State, Nigeria

*Corresponding Author: Oghale Omojuwouvie OKPU

Department of Fine and Applied Arts, Delta State University

Abraka Nigeria

Tel: 08065518636

E-mail:Ookpu@yahoo.com

Received: June 10, 2020 Accepted: July 10, 2020 Published: July 30, 2020

Citation: Oghale OO, Oluwafunmilayo OL (2020) Comprehensive Drafts of Woven Fabrics. J Fashion Technol Textile Eng 8:3.

Abstract

The crux of this paper is based on the pattern drafting of woven fabrics. It is necessary because many textile designers or weavers cannot generate and develop their personal pattern drafts for weaving. It is obvious that they mainly copy other people’s designs to weave. This paper therefore has provided an easy and simple way to learn, focus and develop their original designs to weave. The practical production method is used to create, generate and develop the pattern drafts in this paper. The proper focuses on the components of the pattern draft will surely help to forecast and have a view of the appearance of the design before it is woven on the cloth. In conclusion, the weaver will be able to record and document his/her original works for posterity.

Keywords: Pattern draft, Basic unit, Lifting plan, Threading , Treadling drafts

Introduction

This paper examines the technicalities involved in the drafting of patterns for different structural designs of woven fabrics. It also discusses the factors necessary for the building plan, the interpretation of the notation used to the understanding of the weaver or textile designer. It also states the usefulness of these symbols to the textile designer or weavers because most of them cannot decipher the signs or symbols used for the building plan of woven fabrics.

Information is gathered from literary source, such as artistic journals, books and internet. The practical production technique is used to create, generate and concretized the building plans by the use of the weaving formula associated with the building plan. The factors or the components of the comprehensive pattern draft on point paper are discussed and illustrated as necessary.

This paper tries to simplify the pattern drafts as building plan of woven designs, to alleviate the fears of most textile designers, who are not conversant with the rules and regulations guiding the pattern drafting of woven fabrics. The draft enables the weaver to forecast or have a fair knowledge of the fabric to be produced as it involves accurate pattern on point paper. The pattern draft also helps the weaver to have deep understanding of the weaving process and eventually enables him/her to produce completely original designs. With this procedure, the weaver will keep a record to all his/her works. It has been observed that a careful study of pattern drafting enables the weaver to understand and develop new original designs for different productions thereby making analysis of weave structures very easy and possible.

This paper is hinged on Roland Barthes Semiotic theory in his book based on mythologies of 1957. Hall et al. [1] discussed Barthes ideology of signs ranging from speech, body language and symbols in paintings, music and Morse code. Hall further stated that Barthes semiotic theory broke down the process of reading signs and focus on their interpretation by different cultures and societies. According to Barthes, signs had both a signifier being the physical form of a sign as we perceive it through our senses or the signified or meaning that is interpreted. He also believed that every ideological sign is either a denotative sign system or a connotative sign. This is what the graphical notations of drafting plan in weaving is built upon. Only those who can understand and interpret the signs would be able to lay the foundation of the pattern drafting on the loom and weave the structural design as the woven fabric is formulation or fabricated.

Pattern Drafting

Pattern drafting according to Black et al. [2] is a set of mark or characters used to designate the order in which the threads are drawn into the heddle to form the weave. She also observed that there are a lot of variations in the recording of these patterns drafting. This depends on the various weavers in different countries, as well as different parts of the same country and at different periods devised their own methods of draft writing. Some resemble short hand in their brevity while others are long.

Brown [3] opined that amateur weaver is always confronted with mysterious diagrams marked up with blacken squares, or Xs or Os or numbers which are regarded as patterns drafts. These drafts represent a code by which the weaver can thread the heddles of a multiharness loom so that certain sequences of threads can be raised or lowered. It automatically means that two shaft loom cannot produce structural weaves because we do not need the code as threading the warp is alternately through heddles on the first and second harnesses. However, for the so-called structural weaves where sometimes very complicated sequences of threads are raised and lowered, the weaver needs a kind of simplified guidance and direction for threading the heddles and this is where the draft is indispensable. Hence Chetwynd et al. [4] stated that, it is very necessary for a weaver to understand the basic principles of drafting which is a formular.

Although pattern drafting is regarded as a system of notation used to represent graphically the appearance and mechanics of a weave, it is advisable for a weaver to be able to decode and understand the signs embedded in the drafting she further stated that drafting system is a very serious and tedious exercise if a weaver wants to be creative and innovative [5].

Bird J et al. [6] opined that “pattern drafts” are usually plotted on graph paper, so that one may see the design as it would appear on the face of the fabric. Chetwynd et al. [7] in his book “sample weaving” postulated that drafting on graph paper is an important method of bridging the gap between the origin design idea and the actual fabric. He believes it is quite frustrating when a weaver is unable to try an idea because he/she does not know how to thread the pattern on the loom. This is the aspect the researches called “laying of the foundation” or “dressing the loom” for the pattern drafting to be woven into fabric.

Discussion and Analysis

Point Paper (Design Paper)

It is like a general graph paper that is used for mathematical calculation. It is ruled with vertical and horizontal lines in a manner suitable for showing weaves and designs. Generally each space between vertical lines represents one warp yarn or end while the horizontal spaces/lines indicate the weft yarn or pick. It should be noted that the point paper/design paper is the main material for creating, generating and developing pattern drafting. Other accessories are pen, pencil, ruler and eraser which are used to draw, develop, arrange, and organize the signs of the draft according to the design formulation.

The principles or factors responsible for Pattern Drafting

Building plan of any house depends on the type of building which may be for a commercial, residential, recreational parks and markets. All these differ in their architectural planning. This also applies to the building planning of woven fabrics for dress wears, furniture and office wears. This also depends on the type of loom used for the formulation.

The pattern draft of this paper is directed to the manual four (4) shaft floor loom which is manipulated by the hands at the top and the leg on the pedals at the bottom. So the bottom shedding technique is being used from the starting point.

The following are the main factors or components of a detailed comprehensive pattern draft on a point paper. The Components of patterns drafting can also be created, generated and developed with the aid of a soft-ware program for drafting patterns in computer. It is not easily available hence the common use of manual creation are Basic unit, Unit pattern, Weave plan/Design, Draft (threading draft), Lifting plan, peg plan, tie-up, Pedals (draft)Treading draft, Sectional diagrams divided in two which are Warp and Weft

Before the weaver starts drafting he/she should adhere to the manner of selection. Even number should not follow even number, and odd number should not follow odd number in the selection of the numbers from 1, 2, 3 and 4 of each warp yarn to be threaded.

Now, just visualize the top of a four-shaft floor loom, you will be looking at the four harnesses as it will appear as in Figure 1.

Then draw the four harnesses on a point paper/graph paper. Every square represents a space where a single heddle could be threaded on these harnesses as in Figure 2.

Interpretation and Results

Basic Unit

This is the first unit of the pattern created, which is repeated to formulate the unit pattern. It shows how the arrangement of the picks (weft yarn) on the warp yarns on the four shaft/harnesses. This is shown on Figure 3. The dark areas show where the warp yarns are over the weft yarns.

Unit Pattern

This is the translation and development of the Basic Unit to the Unit pattern in a repeated form, to generate the design. Let us take the formation of a pattern of the following numbers, making sure that odd number do not follow odd number and even number do not follow even number: 12343234, 12343234. This means that the design repeats in every eight-warp end as shown in the unit pattern Figure 4 below.

Weave Plan

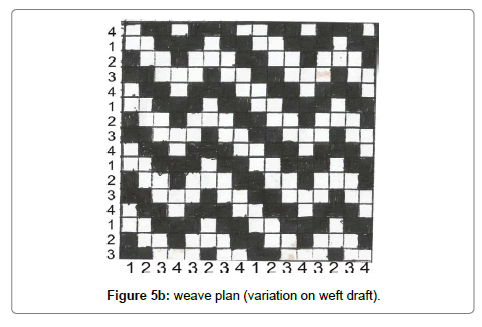

This is the visual appearance of the pattern created and it is the representation of the order of interlacing of the ends and picks. Each small square on the design/point paper represents a point of interlacing. When the warp is over (above) the weft, the small square in the design paper is painted black. When the weft is over the warp, the small square in the design paper is left blank as determined by the design pattern on Figure 5a & Figure 5b. This pattern will show exactly on the woven fabric as designed. The warp draft and the weft draft are the same – 12343234. This is repeated according to the width and length of fabric desired.

The Threading or Drawing- In Plan (Draft)

This is the graphical representation of the order in which the warp yarns are threaded through the eye of the heddles. This is referred to as a draw or a draft. Below is a straight draft notation on a four – harness loom showing a threading arrangement based on a unit of 4 warps repeated across the loom as shown on Figure 6.

When sitting on the loom, the first shaft or harness facing the weaver is regarded as shaft 1, next is 2, the next is 3 and so forth with their respective heddles. According to the above draft:-

Warp 1 is threaded through harness 1

Warp 2 is threaded through harness 2

Warp 3 is threaded through harness 3

And warp 4 is threaded through harness 4 and once one unit or repeat has been completed, the pattern begins again. The draft is normally read from the bottom to top as the harnesses occur from the front to the back of the loom.

Therefore for the draft of weave plan of 5a and 5b will read as follows:-

12343234 as a unit and it will be threaded again for the draft to be repeated as shown below in Figure 7.

The Lifting Plan/Peg Plan/Tie-Up

The lifting plan defines the selection of heddles to be lifted or lowered on each successive insertion of weft yarn. In a lifting plan, the vertical spaces represent the heald or heddle shafts and the horizontal spaces indicate the picks (weft). The lifting is derived from the weave plan of any pattern. The lifting below, in Figure 8 is derived from weave plan 5a. The horizontal squares or spaces painted represent where the warp yarn is over the weft yarn during weaving. Where the weft yarn is over the warp yarn, it is left blank.

Pedals/Treading (Draft)

This is the tying of the ropes/twines from the shafts to the lams down to the treadles. In fact this is the final factor to be considered as it is the order of pressing the treadles to create their respective sheds as shown on the pedal or Treadling Draft below as shown on Figure 9.

From the above graphical notation, the unshaded and shaded squares horizontally represent the shafts while the shaded and unshaded squares vertically represent the treadles or pedals. It shows that when Treadle one, represented by T1 is pressed down, shafts 1 and 2 (represented by Sh1 & Sh2) will be lowered.

So Treadle 1 will lower shafts 1 & 2

Treadle 2 will lower shafts 2 & 3

Treadle 3 will lower shafts 3 & 4

Treadle 4 will lower shafts 1 & 4

Normally plain weave is used as the binding force to make the structural weave more taut, strong and firm.

So Treadle 5 will lower shafts 1 & 3 and

Treadle 6 will lower shafts 2 & 4

Treadling Order

The treadling order indicates the order of lifting of a particular structure weave as it appears on the surface of the woven cloth. For example in Figure 5a lifting plan, the first(1) weft that is thrown on shaft 1, will show a slash. The slashes will show according to the treadles lowered to execute the pattern design. Therefore the treadling order should correspond with the lifting plan numbering on the right hand side by the weave plan. The treadling order is on Figure 10 and the fixture of the slashing is according to the pattern draft.

Sectional Diagrams

Warp

Weft

The sectional diagrams represent the warp and weft movement in the weave plan. The vertical shaded spaces represent the warp yarn over the weft thread or yarn while the unshaded (white) spaces on the horizontal lines represent the weft movement as it is woven on the fabric.

The Comprehensive Draft Pattern

The Result is a conglomeration of all the factors or components of pattern drafting as seen on Figure 11. At a glance you can see and meditate on how the pattern draft will look like and develop yours. It should be noted that if the comprehensive draft pattern is not well represented, the result on the woven fabric will be faulty. The draft pattern will not appear on the surface of the woven fabric just like that on the draft paper. There is no guess work on pattern drafting. It must be exact, using standardized woven structure formular, hence only a patient, stable, focus dedicated and diligent student or weaver can embark on pattern drafts for structural weave patterns.

Conclusion

The paper has discussed extensively on the components or factors used for pattern drafting. It has successfully simplified the whole process by explaining all the factors one after the other for easy understanding so that any textile designer or weaver willing to create, generate, develop and analyse his/her pattern drafts can easily do so. Continuous practicing of these graphical notations will make the individual develop and record all his/her original pattern draft for posterity. All these pattern drafts are used mainly by the multi-harness looms which are very efficient in terms of production and fastness as projected by Gyampoh A, et al. [8].

From all indication, pattern drafting is an interesting, creative and innovative experience worth knowing. It is a process of mental tasking which no TOM, DICK and HARRY can handle. It is mainly for practicing professional or weavers that are skillful [9]. Anybody who is willing to learn, create and develop the threading draft using the standard Basic Unit of Bottom shad can excel very well after many attempts of pattern drafting. Hence Seymor R [10] stated that the process of designing leads to innovative products which require skillful knowledge and Redmore N [11] also observed that weavers have continued to strive to improve and make new surface qualities.

Acknowledgment

The writers of this paper acknowledged all our colleagues that contributed in one way or the other to make sure that this write-up is successful, especially in the area of the interpretation of the pattern drafts. We are also very grateful to our families for their support financially, morally and prayerfully.

References

- Hall, Sean (2016) “Roland Barthes and His Semiotic Theory” UK Essays in Cultural Studies. Goldsmiths, University of London.

- Black, Mary E (1980) Key to weaving: A Textbook of Hand Weaving for the Beginning Weaver Macmillan Publishing Co. INC. New York.

- Brown, Rachel (1979) The Weaving, Spinning and Dyeing Book. Routledye & Kegan Paul Ltd London and Henley.

- Chetwynd, Hilary (1977) Weaving in easy steps A Studio Vista Book. Cassell & Collier Macmillan Publishes Ltd. New York.

- Okpu O (2014) “The Introduction” Exploring Four-shaft loom for production of Structural Drafts for weaving fabrics, Ph.D Exhibition Catelogue, Ajiginni Margaret Irobunor Delta State University, Abraka.

- Bird J (1997) Creative Projects for the Home Country Fabric Style. Trafargar Squares Publishing USA.

- Chetwynd, Hilary (1969) Sample Weaving. A Studies Vista. Cassell & Collier Macmillan Publishers Ltd, New York.

- Gyampoh A, Albert (1999) Contemporary Adaptation of the Nigerian Traditional Textile Industry in Delta State. First Rhythms 1999 Independence Art Exhibition. Society of Nigerian Artists, Delta State Chapter.

- Gyampoh A, Albert (2020) Textile Consultant, Personal Interview 15/5/2020

- Seymor R (2002) what is Design, Design Council’s: Design in business week. Retrieved 20 Nov. 2019.

- Redmore Nicole (2011). Textile Design: Principles Advances and Application. Wood head Publishing Ltd, Oxford, UK.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi