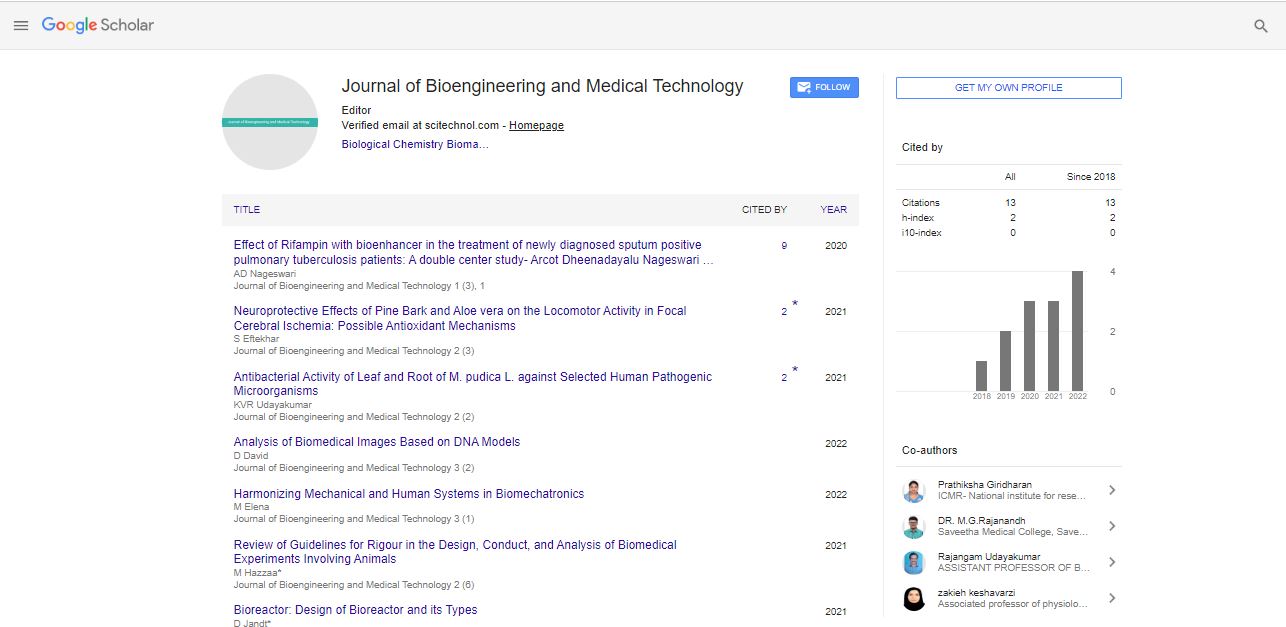

Short Communication, J Bioeng Med Technol Vol: 4 Issue: 1

Cellular Engineering is the Application of Materials Patterned on a Nano and Micro-Metric Scale

Ben Ahmed*

Department of Mechanical Engineering, KN Toosi University of Technology, Tehran, Iran

*Corresponding Author: Ben Ahmed

Department of Mechanical Engineering, KN Toosi University of Technology, Tehran, Iran

E-mail: benahmed@gmail.com

Received date: 08 March, 2022, Manuscript No. JBMT-22-57164; Editor assigned date: 11 March, 2022, PreQC No. JBMT-22-57164 (PQ); Reviewed date: 25 March, 2022, QC No. JBMT-22-57164; Revised date: 09 May, 2022, Manuscript No. JBMT-22-57164 (R); Published date: 16 May, 2022, DOI: 10.4172/JBMT.100057

Citation: Ahmed B (2022) Cellular Engineering is the Application of Materials Patterned on a Nano and Micro-Metric Scale. J Bioeng Med Technol 3:3

Abstract

An animal's biological cells are arranged in various patterns, with the orientation and alignment of the cells varying depending on the tissue's function. Skin, for example, is composed of tightly packed cells, however this sheet can be extended (a bit) in the plane of the sheet. A tendon, on the other hand, is roughly cylindrical in shape and is made up of cells that are lined in the cylindrical axis' direction. Cues are delivered to proliferating cells that influence their eventual position and orientation during the development of the adult animal from the egg. These cues might be chemical in nature, such as the presence of adhesion-promoting proteins, or they can be merely physical, such as a cell's sensitivity to its surroundings' topography. Not just in developmental biology, but also in tissue engineering, an understanding of the signals that control cell placement and alignment is critical. The new cells must be aligned and positioned correctly if tissue is to be healed. Organ reconstruction is considerably more difficult; cells of various types must be oriented appropriately to one another, and the entire complex of tissue cells, blood vessels, and sensory cells (for example, nerve cells) must work together correctly.

Keywords: Adhesion; Hydroxyapatite; Microchip; Microstructure; Proliferation

Introduction

Methods for patterned adhesion and cell guidance

Pattern definition is the initial step in the production of a patterned substrate. Here, a focused beam of radiation is scanned over the resist and turned on and off as needed to define the pattern in a radiationsensitive substance (a resist). Electrons are the most common choice for main pattern definition radiation because electron beam lithography can achieve a resolution of 10 nm and electrons are easily scanned and switched on and off, allowing transmission speeds of up to 25 million picture elements (pixels) per second [1]. In a current high resolution electron beam writing system, an electron beam can be deflected over an area of around 1 by 1 mm; after writing such a field, the sample table is moved under interferometric control, and the fields are stitched together to produce the entire pattern. In the best machines, stitching accuracy is currently around 20 nm. Surprisingly, this stitching precision is insufficient for some biological applications [2].

The basic pattern definition stage in silicon microelectronics photolithography is to construct a (photo) mask, which is a glass plate with a pattern in a light-absorbing metal layer. A focused optical beam is used to create some photo masks [3]. This mask is lit with a flood stream of light, allowing the design to be printed onto a photoresist coated wafer. This parallel method allows for a considerably faster pattern transfer into the resist [4].

Primary pattern definition using a (expensive) electron beam machine can be avoided in some situations by using 'Natural lithography,' in which the pattern is formed via a natural process. Allowing 50 nm gold beads to fall into a derivatized surface that causes them to stay, for example, can result in a random pattern of 50 nm diameter circles. Wherever they may be used, such tactics are beneficial [5].

After the pattern has been defined as a relief pattern in the resist, it can be transferred by adding or subtracting material. The resist is used as a stencil in additive pattern transfer. To generate a pattern of adhesive peptides, for example, the substrate could be coated first with a silane layer to attach a following peptide, then with resist [6]. The resist grew into a relief pattern when exposed to light through a mask, and the entire sample was coated with peptide. A pattern in peptide is left once the photoresist is removed in an appropriate solvent. Lift-off occurs in electron device manufacturing when metal is deposited onto a patterned resist pattern and the resist is dissolved in a solvent [8].

Description

In subtractive processing, the resist is utilized as a masking layer to prevent etching, as its name suggests. Wet chemicals generally etch isotropically, making high aspect ratio features difficult. Dry etching is the process of etching in a low pressure gaseous rf discharge with the help of ions to speed up the creation of radicals that react with the exposed substrate to produce volatile chemicals [9].

The gas is chosen so that it can decompose in the discharge to produce useful radicals; for example, CHF3 produces F radicals, which etch fused silica (SiO2 a useful substrate for cell growth) by forming SiF4 and O2, both of which are gases at room temperature and can be pumped away in a vacuum system. Dry etching has the advantage that changing the etching conditions pressure, flow, rf power, and so on can frequently change the profile of the etched feature [10].

A relief profile can be created in a material using lithography and dry etching. This can then be used directly in cell research.

However, it is frequently more practical to go one step further and use the produced relief design as a stamp, die, or mould to transfer the pattern onto the actual material for the cells. For acceptable statistics, cell experiments require a somewhat large play park an area of 10 by 10 mm2 is frequently required. When this area is made up of densely packed nanometric sized features, the amount of electron beam time required is frequently significant [11]. Many polymeric materials are incompatible with the solvents used with photo resist, even if the necessary pattern may be created by printing resist with light [12].

For example, a die consisting of a 7 m wide groove and 3 m deep ridges was created in fused silica during work to make grooves in a biodegradable polymer for use in prosthesis for the rehabilitation of tendons. Between the die and a flat sheet of fused silica, a sheet of biodegradable polymer was inserted and heated until the polymer melted. The grooved polymer was removed and used once it had cooled. The recreation of the die's characteristics was extraordinarily accurate even 20 nm flaws were precisely duplicated. This method is similar to mould injection (which is used to make CD discs), in which molten polymer is injected onto a die and then cooled [13].

Embossing is another option for using the die. In a press, a die is pressed into the heated polymer [14]. An electron beam machine was used to write a pattern in PMMA (an electron beam resists) that was then over-coated with 30 nm of nickel chromium [15]. The fused silica was etched in CHF3 after the metal was lifted off. The pillars have an 80 nanometer base diameter and a 200 nanometer center to center spacing [16]. The somewhat tapered profile is advantageous for easy removal of the die from the polymer. The sharpness of the holes created by this die was determined to be outstanding [17].

Mechanical transfer includes things like moulding and embossing. Whiteside's group demonstrated that mechanical transfer may also be utilized to transfer chemical patterns on a substrate [18]. The essence of this very elegant technique is that a die is cast in silicone rubber, and this silicone rubber stamp is inked with the desired protein or bit of protein (peptide); the protein is transferred to the substrate with the pattern of the stamp when the stamp is pressed onto a substrate preconditioned with a sticky layer [19,20].

Conclusion

Pediatric TBIs are specifically moderate to slight in severity. Road site visitor’s twist of fate is the principle motive, accompanied with the aid of using falls predominantly from storey homes. The full size range of pedestrian injuries begets a clarion name to defend youngsters with the aid of using instituting and imposing suitable site visitor’s regulations. Likewise the want to position toddler safety measures whilst constructing story homes have additionally been underscored with the aid of using this look at. Irrespective of the severity of damage, a practical method of ok resuscitation and group of suitable remedy measures yields profitable results. Pediatric TBI is related to numerous exclusive traits that fluctuate from adults and are as a result of age associated anatomical and physiological differences, sample of accidents primarily based totally at the bodily cap potential of the toddler and problem in neurological assessment in youngsters.

References

- Wu SJ, De Jonghe LC, Rahaman MN (1996) Sintering of nanophase g-Al2O3 powder. J Am Ceram Soc 79:2207–2211. [Crossref]

- Wilkinson CDW, Riehle M, Wood M, Gallagher J, Curtis SG (2002) The use of materials patterned on a nano and micro-metric scale in cellular engineering. Mater Sci Eng C 19: 263–269. [Googlescholar][Crossref]

- Wan Y, Wang Y, Liu Z, Qu X, Han B, et al. (2005) Adhesion and proliferation of OCT-1 osteoblast-like cells on micro and nano-scale topography structured poly(l-lactide). Biomaterials 26: 4453–4459. [Googlescholar][Crossref][Indexed]

- Turner AM, Dowell N, Turner SW, Kam L, Isaacson M, et al. Attachment of astroglial cells to microfabricated pillar arrays of different geometries. J Biomed Mater Res 51:430–441. [Googlescholar] [Crossref][Indexed]

- Stanto MM, Rankenberg JM, Park BW, McGimpsey WG, Malcuit C (2014) Cell behavior on surface modified Polydimethylsiloxane (PDMS). Macromol Biosci 14: 953–964. [Googlescholar][Crossref][Indexed]

- Spatz JP, Geige B (2007) Environmental sensing through focal adhesions. Method Cell Biol 83:89–1 [Googlescholar][Crossref][Indexed]

- Rimondini L, Faré S, Brambilla E, Felloni A, Consonni C, et al. (1997) The effect of surface roughness on early in vivo plaque colonization on titanium. J Periodontol 68:556–562. [Googlescholar][Crossref][Indexed]

- Puckett SD, Taylor E, Raimondo T, Webster TJ (2010) The relationship between the nanostructure of titanium surfaces and bacterial attachment. Biomaterials 31:706–713. [Googlescholar] [Crossref][Indexed]

- Parent CA, Devreotes PN (1999) A cell’s sense of direction. Science 284:765–770.[Googlescholar] [Crossref][Indexed]

- Milner KR, Siedlecki CA (2007) Submicron poly (L-lactic acid) pillars affect fibroblast adhesion and proliferation. J Biomed Mater Res A 82A: 80–91. [Googlescholar][Crossref][Indexed]

- Liu DM, Troczynski T, Tseng WJ (2001) Water-based sol-gel synthesis of hydroxyapatite: process development. Biomaterials; 22: 1721–1730. [Googlescholar][Crossref][Indexed]

- Klabunde KJ, Stark J, Koper O, Mohs C, Park DG, et al. (1996) Nanocrystals as stoichiometric reagents with unique surface chemistry. J Phys Chem 100: 12141–12153. [Googlescholar] [Crossref]

- Kidambi S, Lee I, Chan C. Controlling primary hepatocyte adhesion and spreading on protein-free polyelectrolyte multilayer films. J Am Chem Soc 126:16286–16287. [Googlescholar] [Crossref][Indexed]

- Karuri NW, Liliensiek S, Teixeira AI, Abrams G, Campbell S, et al. (2004) Biological length scale topography enhances cell substratum adhesion of human corneal epithelial cells. J Cell Sci 117: 3153–3164. [Googlescholar][Crossref][Indexed]

- Harrison RG (1911) On the stereotropism of embryonic cells. Science 34: 279–281. [Googlescholar][Crossref][Indexed]

- Hadrich A, Lautié A, Mhiri T (2001) Vibrational study and fluorescence bands in the FT-Raman spectra of Ca(10-x)Pb(x)(PO4)6(OH)2compounds. Spectrochim Acta A 57:1673–1681. [Googlescholar][Crossref][Indexed]

- Habibovic P, Yuan H, van den Doel M, Sees TM, van Blitterswijk CA, et al. (2006) Relevance of osteoinductive biomaterials in critical-sized orthotopic defect. J Orthop Res 24:867–876. [Googlescholar][Crossref][Indexed]

- Fujita S, Ohshima M, Iwata H (2009) Time-lapse observation of cell alignment on nanogrooved patterns. J R Soc Interface 6: 269–277. [Googlescholar] [Crossref][Indexed]

- Delgado-Ruiz RA, Calvo-Guirado JL, Abboud M, Ramirez-Fernández MP, Maté-Sánchez JE, et al. (2014) Porous titanium granules in critical size defects of rabbit tibia with or without membranes. Int J Oral Sci 6:105–110. [Googlescholar] [Crossref][Indexed]

- Dalby MJ, Riehle MO, Johnstone H, Affrossman S, Curtis ASG (2002) In vitro reaction of endothelial cells to polymer demixed nanotopography. Biomaterials 23: 2945–2954. [Googlescholar] [Crossref][Indexed]

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi